Driving circuit applied to aerospace high-power contactor

A technology for driving circuits and contactors, applied in circuits, relays, electrical components, etc., can solve problems such as space occupation, weight, and large driving current, and achieve the effects of avoiding voltage spikes, small driving current, and safe state detection circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

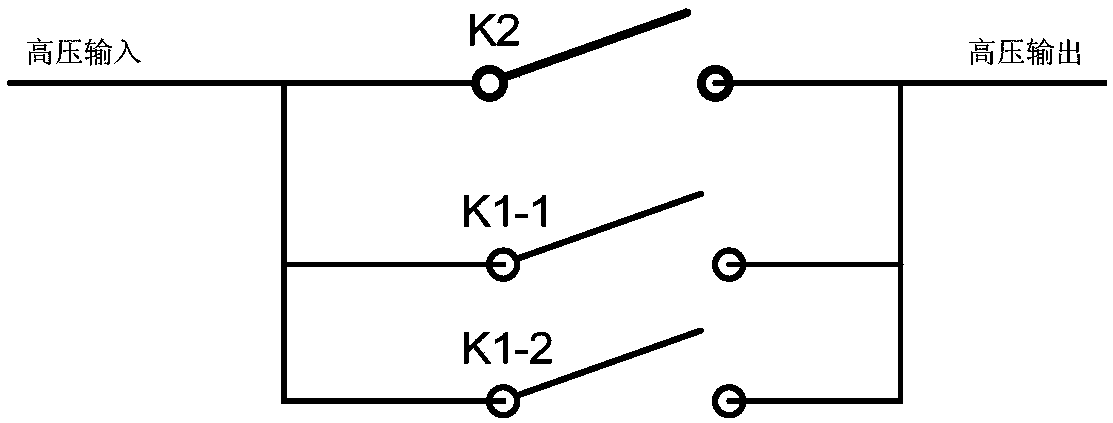

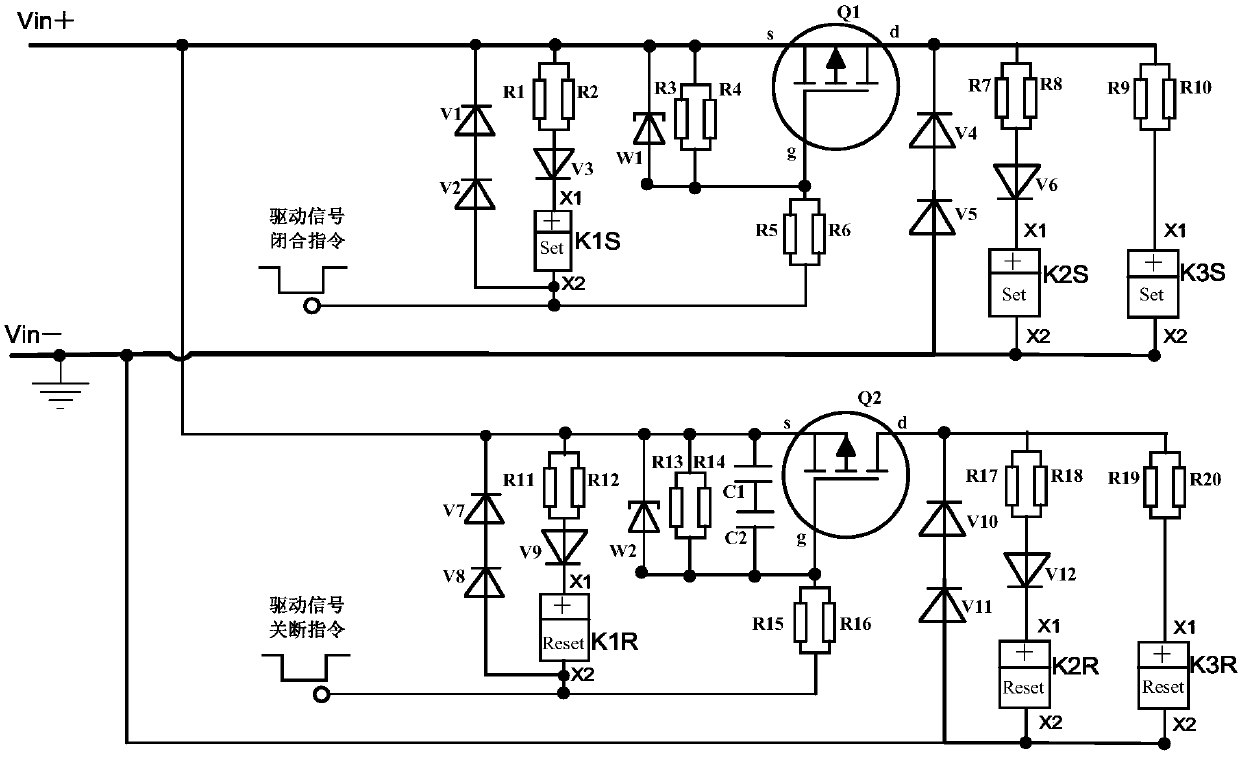

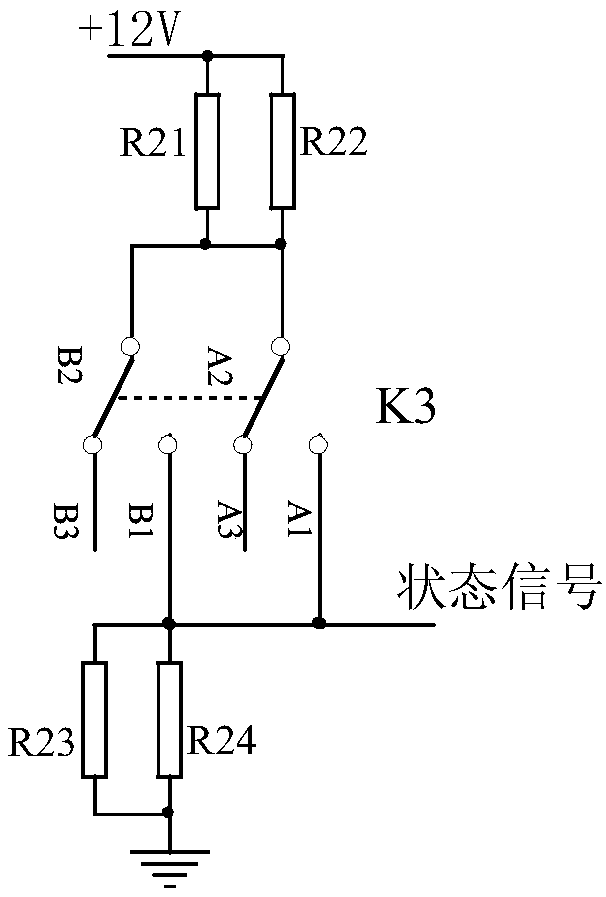

[0035] Although the rated current of the contacts of aerospace contactors is much greater than that of traditional relays, there are the following disadvantages in application: 1. The required driving current (driving power) is very large; 2. The overall size is large; 3. The weight is large; 4. The contacts of the contactor are single-point, and the driving circuit is also single-point, so the reliability is poor. The present invention proposes a drive circuit for aerospace high-power contactors, which uses relays and contactor power contacts in parallel. The point adopts parallel design, the contactor drive and the relay drive are mutually redundant, and the reliability is high. More ingeniously, through the drive delay design, it is ensured that when the receiving signal is a closing command, the contactor is closed before the relay, and the receiving signal is off. When the command is opened, the relay is disconnected before the contactor, which protects the relay with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com