Three-dimensional integrated circuit heat dissipation system using TSV and RDL

A technology for integrated circuits and heat dissipation systems, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of uneven heat dissipation of three-dimensional integrated circuits and large chip temperature gradients, achieve large coverage, improve heat dissipation efficiency, and improve heat dissipation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the specific embodiments.

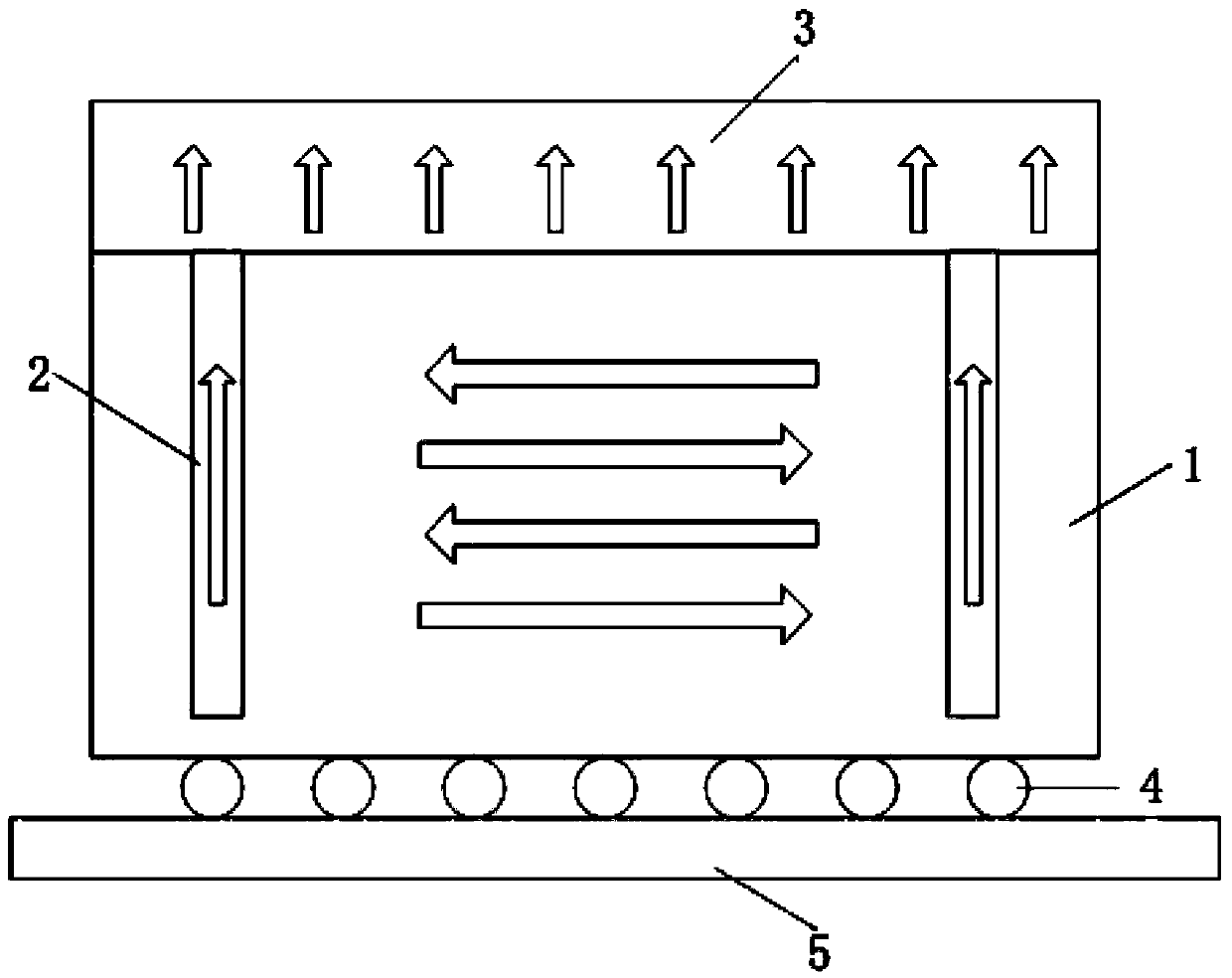

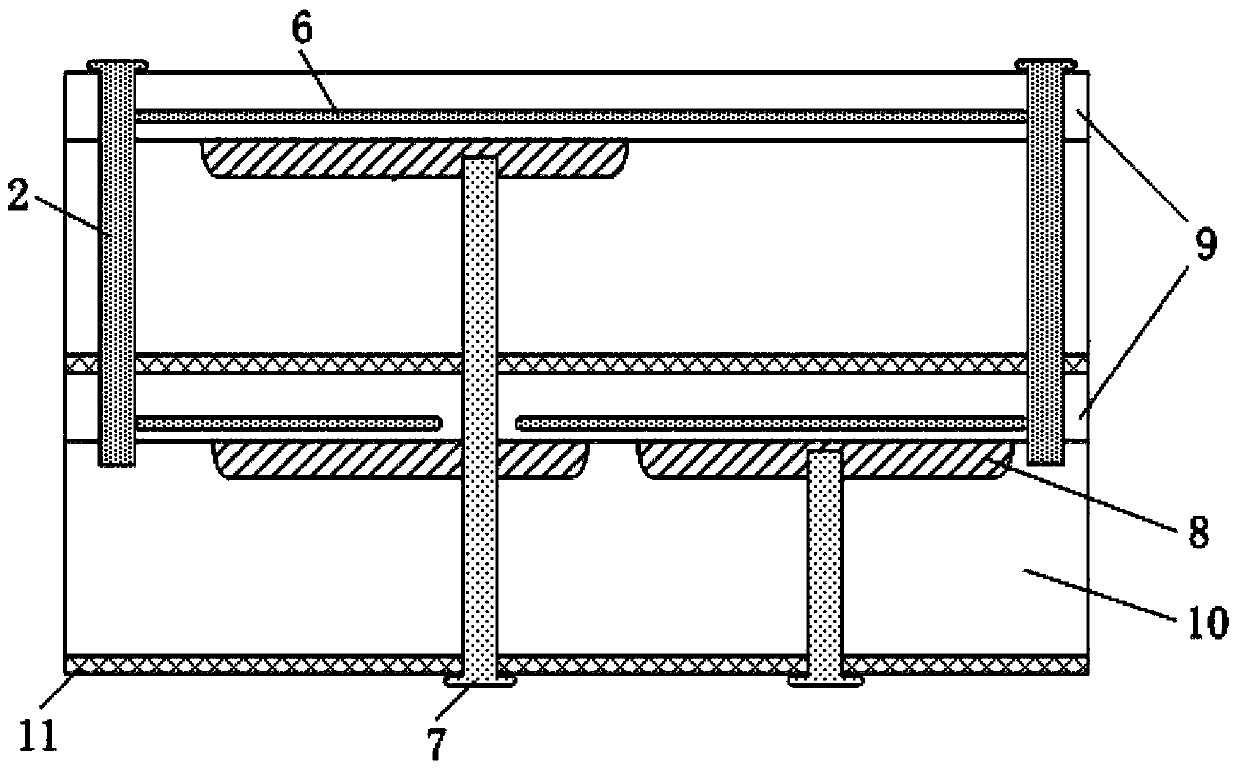

[0020] refer to figure 1 and figure 2 , the present invention is a three-dimensional integrated circuit heat dissipation system using TSV and RDL, wherein the three-dimensional integrated circuit 1 includes a bonding layer 11, a silicon substrate 10 and an active region 8 that are sequentially stacked, and the bonding layer can shield external interference, Improve the stability of the circuit; the silicon substrate is used to carry the active area to form an integrated circuit; functional devices such as transistors are distributed in the active area, which belongs to the core part of the integrated circuit.

[0021] A dielectric layer 9 is deposited on the surface of the silicon substrate 10, and a metal line 6 for absorbing heat in the active area 8 is deposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com