Method for preparing broad bean sauce through synergistic fermentation of multiple bacteria

A collaborative fermentation and multi-strain technology, applied in the field of food processing, can solve problems such as single enzyme system, poor flavor and quality stability, and limited production process control, so as to increase volatile flavor substances, improve safety and reliability, Improvement effect of volatile flavor compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1--5

[0043] 1) Soak beans: Soak dried broad beans in water for 1 hour and drain;

[0044] 2) steamed beans: steam the broad beans obtained in step 1) for 60 minutes, and cool to 35.0°C;

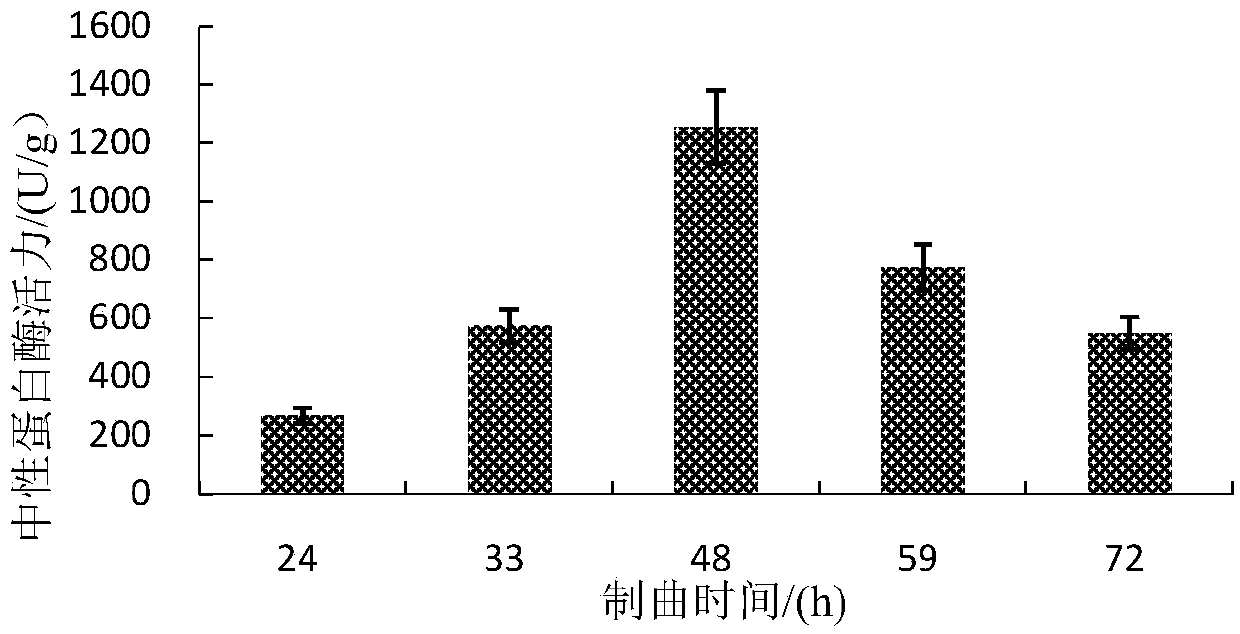

[0045] 3) Inoculation and cultivation: the broad beans obtained in step 2) are mixed with flour, inoculated with Aspergillus oryzae and Aspergillus niger spore powder, and cultured at 30.0°C for 24, 33, 48, 59 and 72 hours respectively;

[0046] The mass ratio of broad beans to flour is 15:1, the mass ratio of Aspergillus oryzae to Aspergillus niger is 1:1, and the inoculum amount accounts for 1% of dry broad bean splits;

[0047] 4) Song turning: Turning the song once every 16 hours, a total of 4 times, to get the finished song;

[0048] 5) Salt water fermentation: add brine to the koji obtained in step 4), the amount of salt accounts for 10% of the quality of the koji, and place it at 50°C for 8 days of incubation and fermentation;

[0049] 6) Synergistic fermentation: adjust the temperature t...

Embodiment 6--10

[0053] 1) Soak beans: Soak dried broad beans in water for 2 hours and drain;

[0054] 2) steamed beans: steam the broad beans obtained in step 1) for 50 minutes, and cool to 40.0°C;

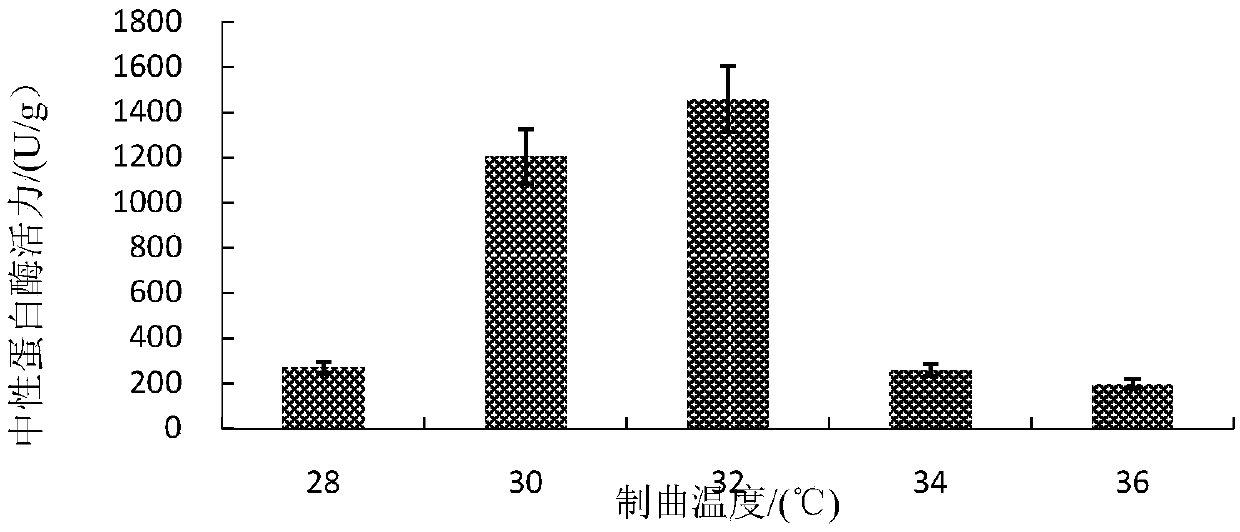

[0055] 3) Inoculation and cultivation: the broad beans obtained in step 2) are mixed with flour, inoculated with Aspergillus oryzae and Aspergillus niger spore powder, and cultured at 28, 30, 32, 34 and 36° C. for 48 hours;

[0056] The mass ratio of broad beans to flour is 5:1, the mass ratio of Aspergillus oryzae to Aspergillus niger is 1:1, and the inoculum amount accounts for 1% of dry broad bean splits;

[0057] 4) Song turning: Turning the song once every 24 hours, a total of 2 times, to get the finished song;

[0058] 5) Salt water fermentation: add salt water to the koji obtained in step 4), the amount of salt accounts for 12% of the koji quality, and place it at 40°C for 12 days of heat preservation and fermentation;

[0059] 6) Synergistic fermentation: adjust the temperature to 25°C,...

Embodiment 11--15

[0063] 1) Soak beans: Soak dried broad beans in water for 1.5 hours and drain;

[0064] 2) steamed beans: steam the broad beans obtained in step 1) for 55 minutes, and cool to 37°C;

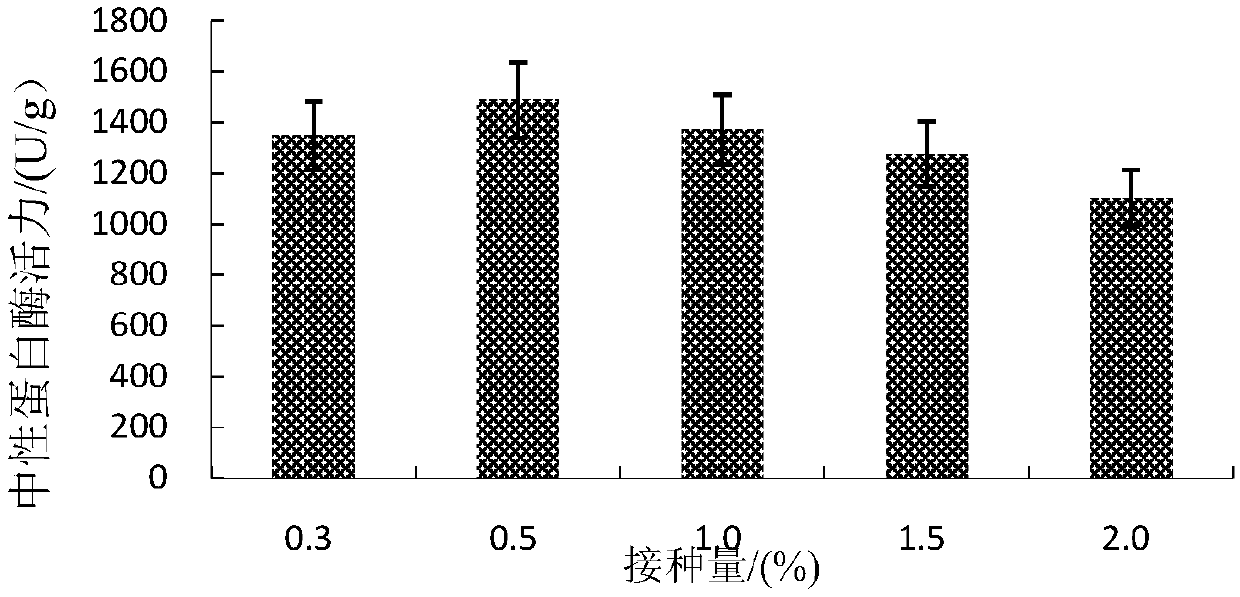

[0065] 3) Inoculation and cultivation: the broad beans obtained in step 2) are mixed with flour, inoculated with Aspergillus oryzae and Aspergillus niger spore powder, and cultured at a temperature of 32.0° C. for 48 hours;

[0066] The mass ratio of broad beans to flour is 10:1, the mass ratio of Aspergillus oryzae to Aspergillus niger is 1:1, and the inoculum amounts account for 0.3%, 0.5%, 1%, 1.5% and 2% of the mass of dry broad beans respectively;

[0067] 4) Song turning: Turning the song every 20 hours, a total of 3 times, to get the finished song;

[0068] 5) Salt water fermentation: add salt water to the koji obtained in step 4), the amount of salt accounts for 11% of the koji mass, and place it at 45°C for 10 days of fermentation;

[0069] 6) Synergistic fermentation: adjust the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com