A kind of potato flour production equipment

A technology for producing equipment and potato flour, applied in the field of potato flour production equipment, can solve the problems of wasting time, slow speed, etc., and achieve the effects of improving efficiency, simplifying manual operation steps, and saving production time and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

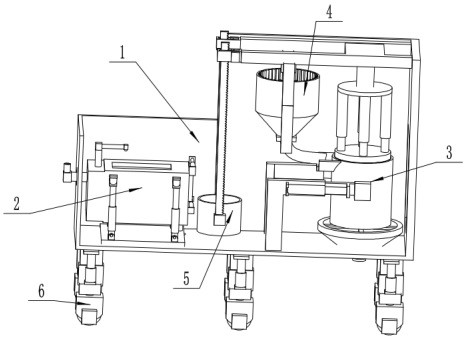

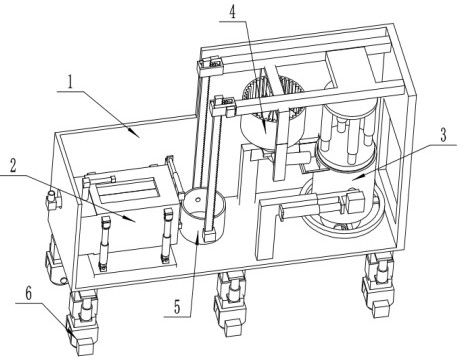

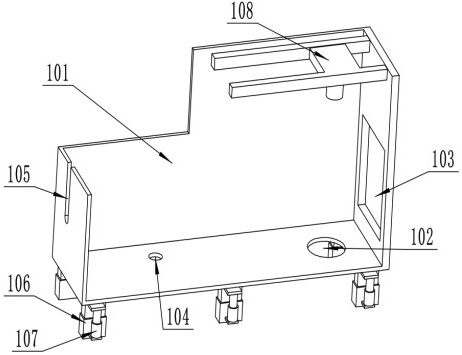

[0021] example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9As shown, a potato flour production equipment comprises a base 1, a cleaning and peeling part 2, a pressing part 3, a pulverizing part 4, a transporting part 5 and a walking part 6, and the cleaning and peeling part 2 is located in the main body of the base 1 The inside of the box 101 is at the left position, and the lower end surface of the bottom plate 201 is fixedly installed on the left position of the bottom plate of the main body box 101 of the base 1. The discharge pipe protrudes from the waste water discharge port 104 of the bottom plate of the main body box 101 ; the extrusion part 3 is located at the right position inside the main body box 101 of the base 1 , and the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com