Processing equipment for coating raw materials

A technology for processing equipment and raw materials, which is applied in the field of processing equipment for coating raw materials, can solve the problems of high labor cost, low efficiency, uneven particle size of ore raw material powder, etc., and achieve the effect of reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further detailed explanation through specific implementation mode below:

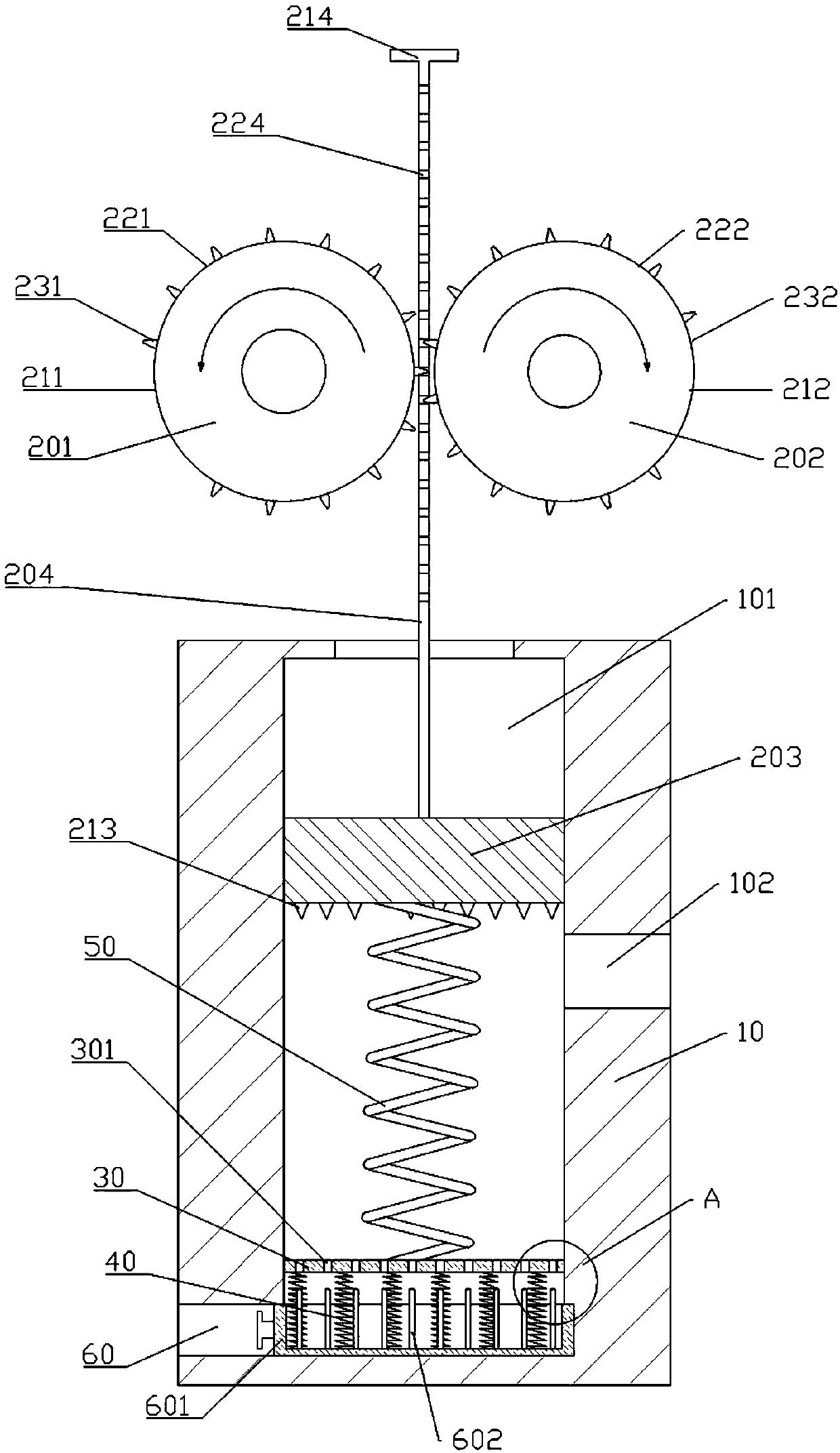

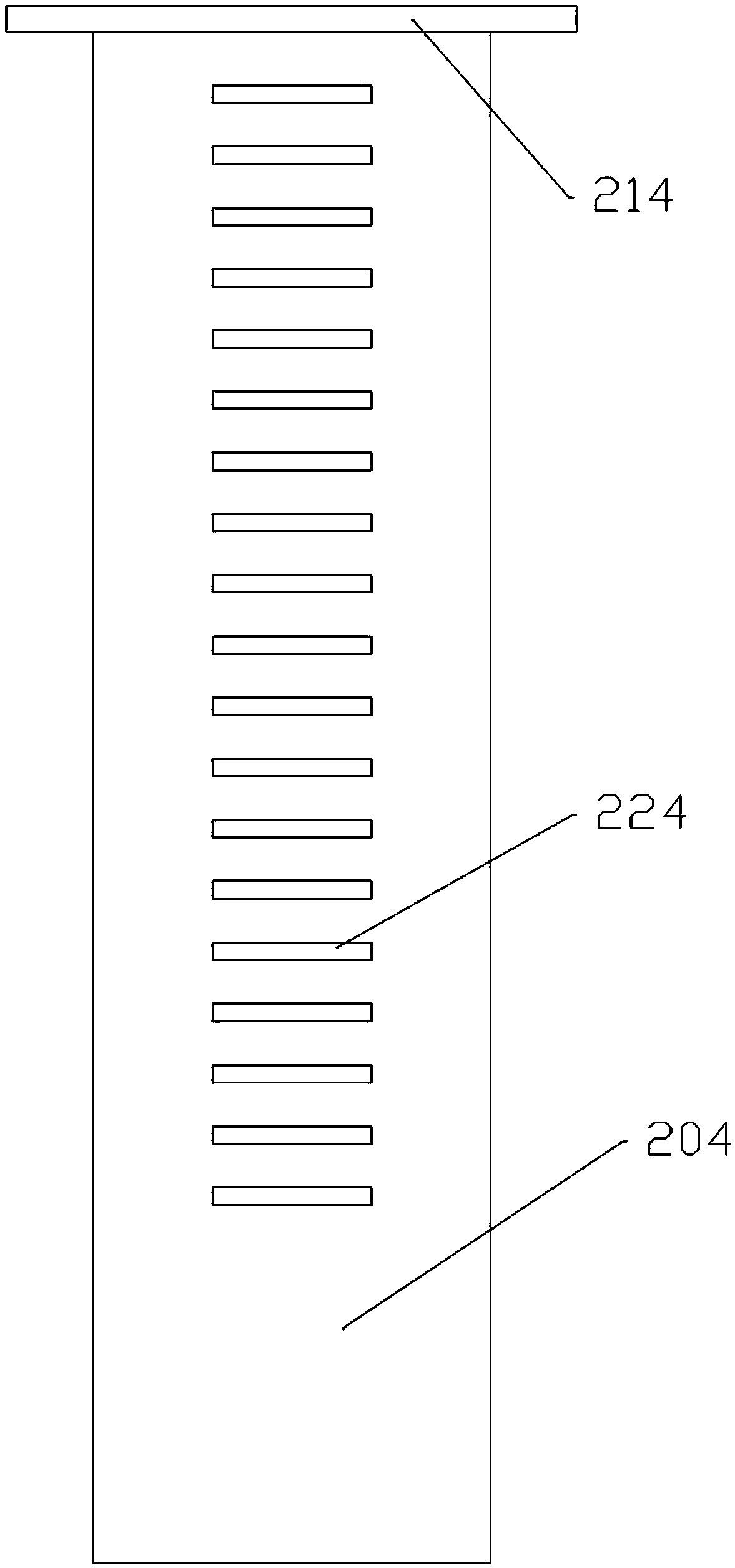

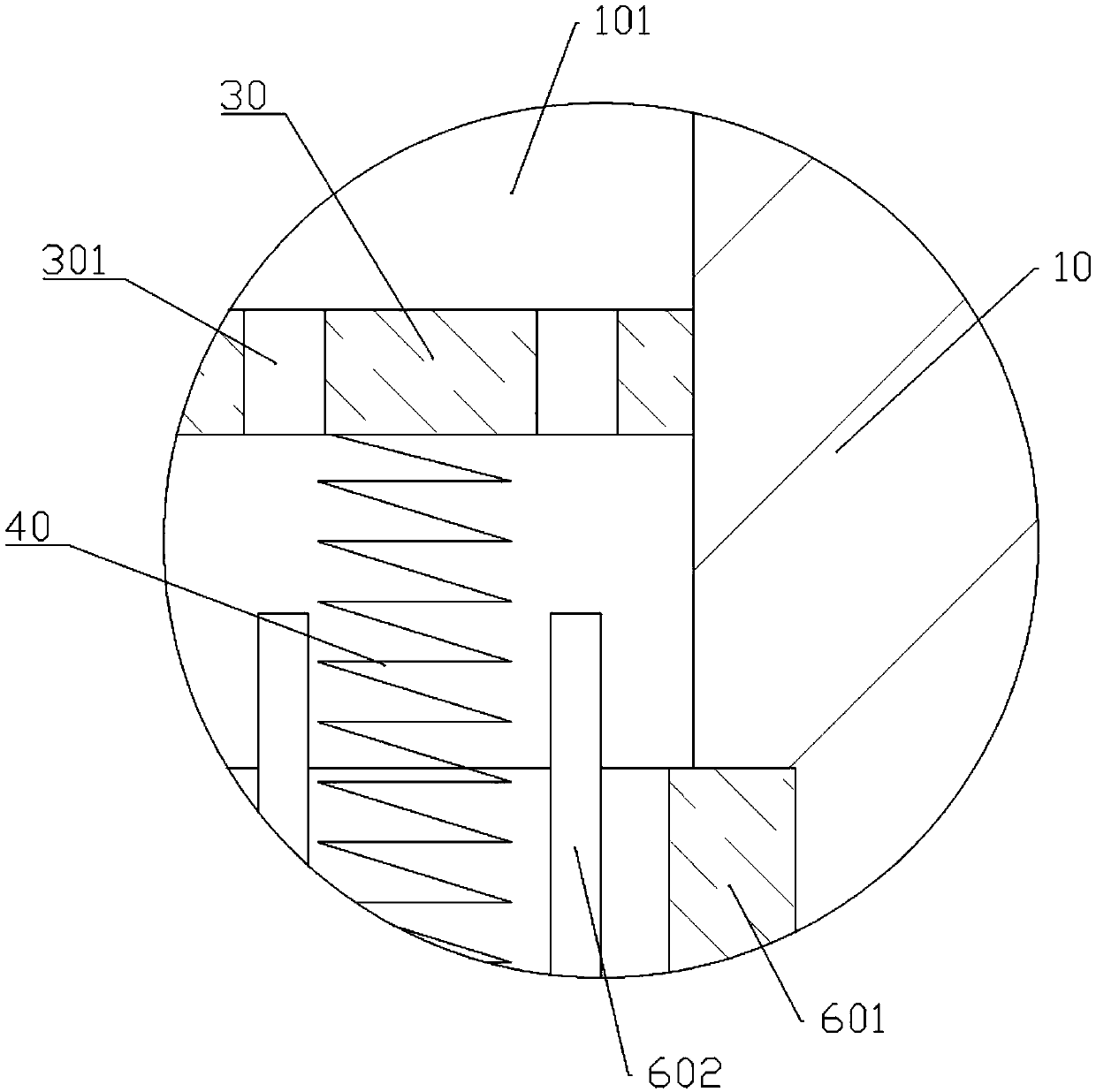

[0028] The reference signs in the drawings of the description include: punching barrel 10, piston cavity 101, feeding port 102, first roller 201, first smooth part 211, first transmission part 221, first tooth 231, second roller 202, first Two smooth parts 212, second transmission part 222, second teeth 232, stamping head 203, tapered teeth 213, moving plate 204, limit block 214, transmission hole 224, partition 30, filter hole 301, first spring 40 , the second spring 50, the collection cavity 60, the collection box 601, and the insertion rod 602.

[0029] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a processing equipment for paint raw materials, including a stamping barrel 10, a stamping mechanism and a vibration mechanism, a piston chamber 101 is formed in the stamping barrel 10, and a feeding port 102 communicating with the piston chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com