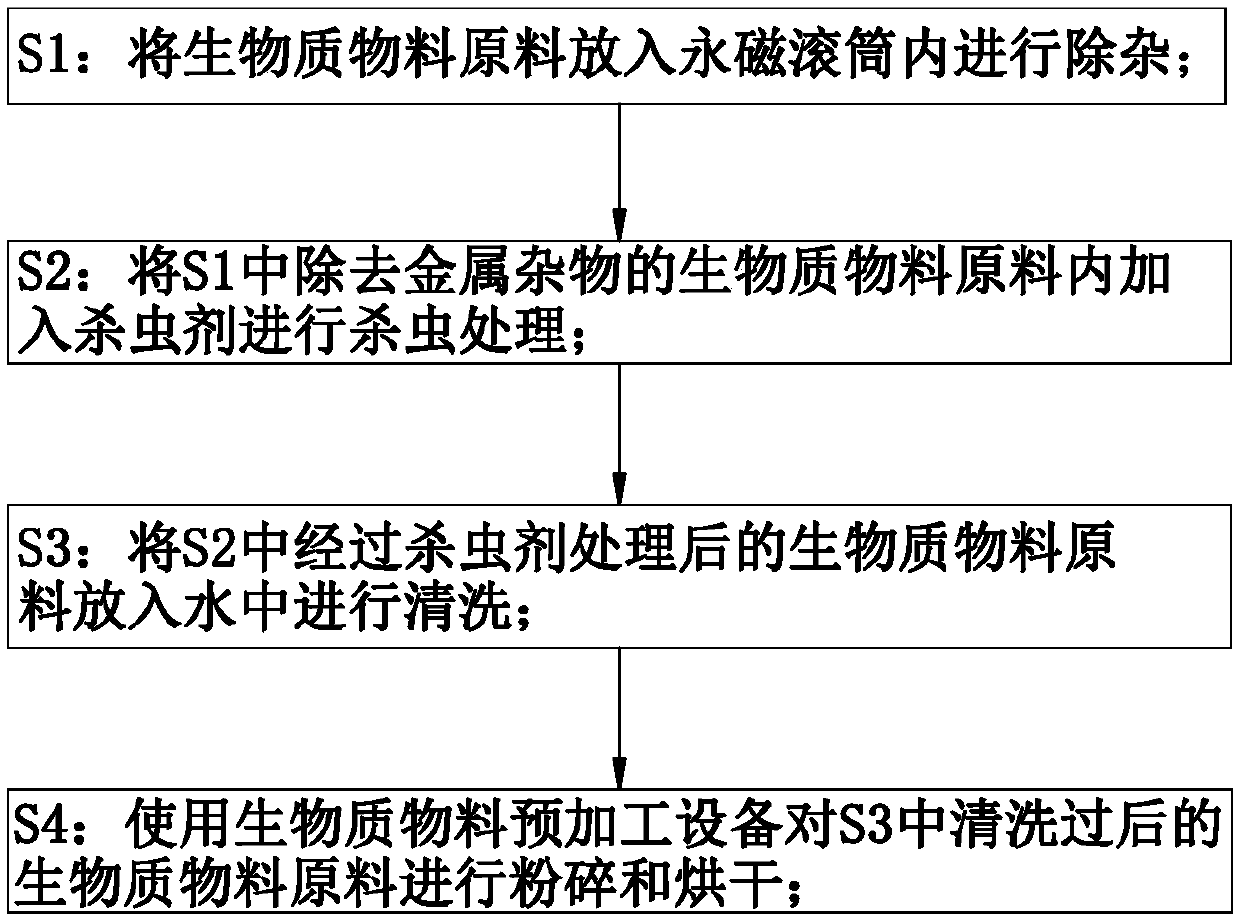

New energy biomass material pretreatment process

A biomass and pretreatment technology, applied in grain treatment, solid waste removal, chemical instruments and methods, etc., can solve the problems of low drying efficiency, no first treatment, single function of biomass material preprocessing equipment, etc. To achieve the effect of convenient operation and speeding up the frequency of flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

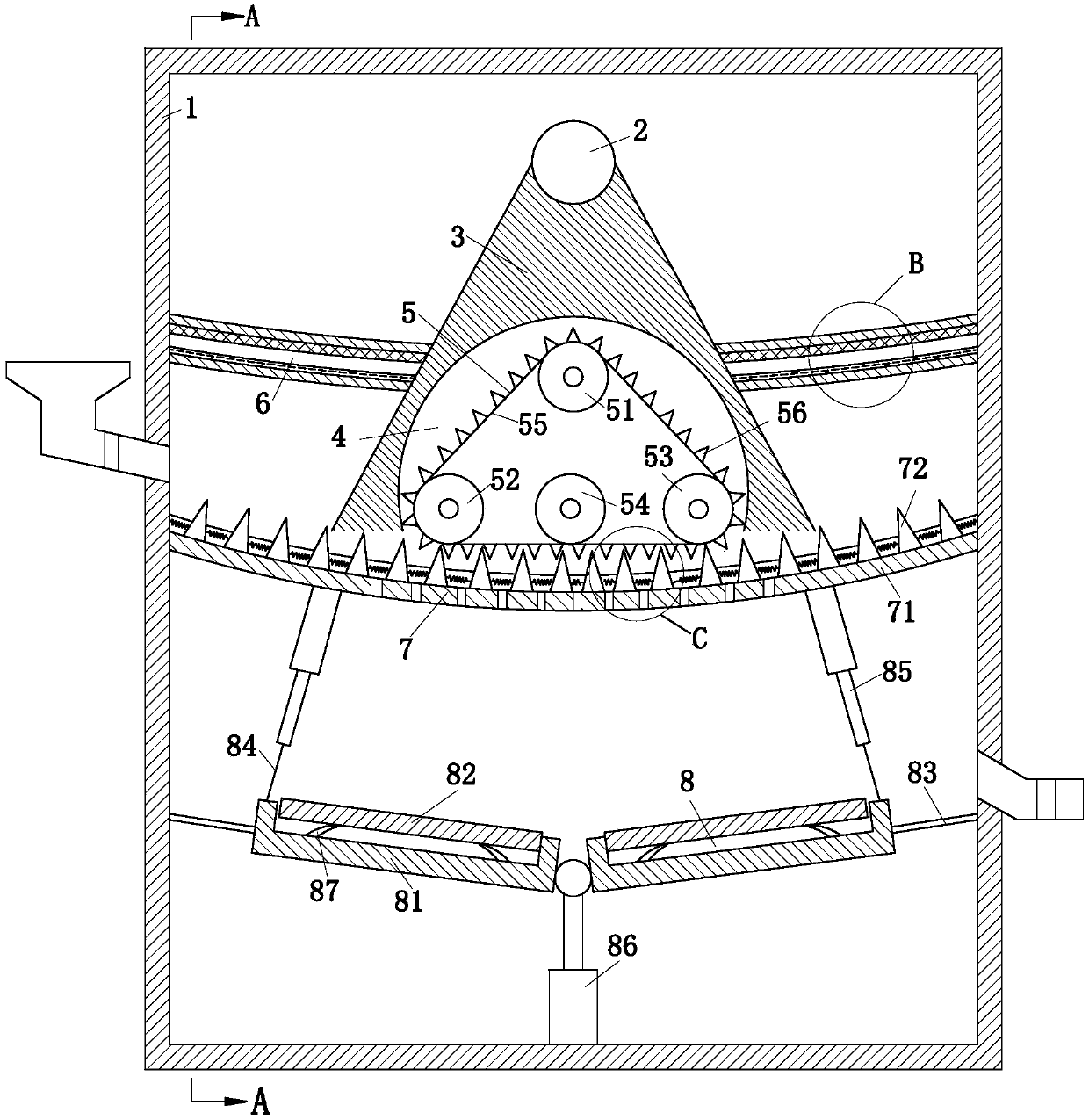

Examples

specific Embodiment approach

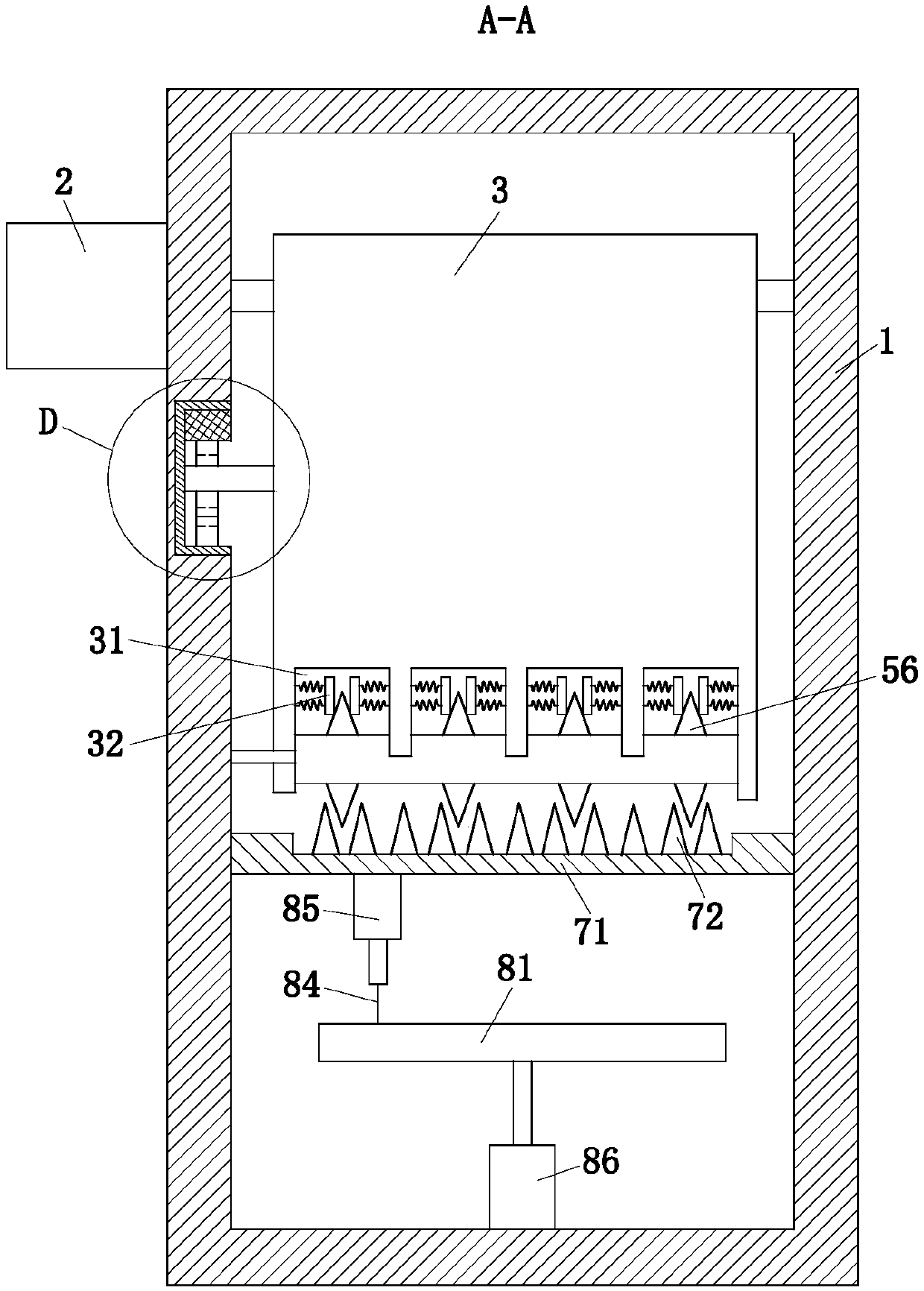

[0042] As a specific embodiment of the present invention, a No. 2 cylinder 86 is provided below the shaking plate 81, the bottom of the No. 2 cylinder 86 is fixedly connected to the bottom of the working box 1, and its output end is fixedly connected to the hinge joint. The cylinder 86 is used to work with the heating unit 8; the present invention can shorten the drying time of the biomass material and increase the drying rate of the biomass material by setting the No. 2 cylinder 86 to work with the heating unit 8.

[0043] As a specific embodiment of the present invention, a rubber tube 87 is provided in the gap between the shaking plate 81 and the heating plate 82, one end of the rubber tube 87 is fixedly connected to the shaking plate 81, and the other end is fixed to the bottom of the heating plate 82. connected; the output end of the No. 2 cylinder 86 provides power for the rubber tube 87 in the process of extending and retracting, and the rubber tube 87 is used to support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com