Centrifugal rotating casting machine with infrared temperature detection function

A technology of infrared temperature and rotary casting, which is applied in the direction of casting equipment, indicating equipment/measuring equipment configuration, manufacturing tools, etc., and can solve the problems of inconvenient putting in/out melting crucible metal castings, high pot wall temperature, and low work efficiency, etc. , to achieve the effects of simple and easy-to-understand touch interface, uniform metal smelting, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now the present invention is further described in conjunction with description of drawings and embodiments:

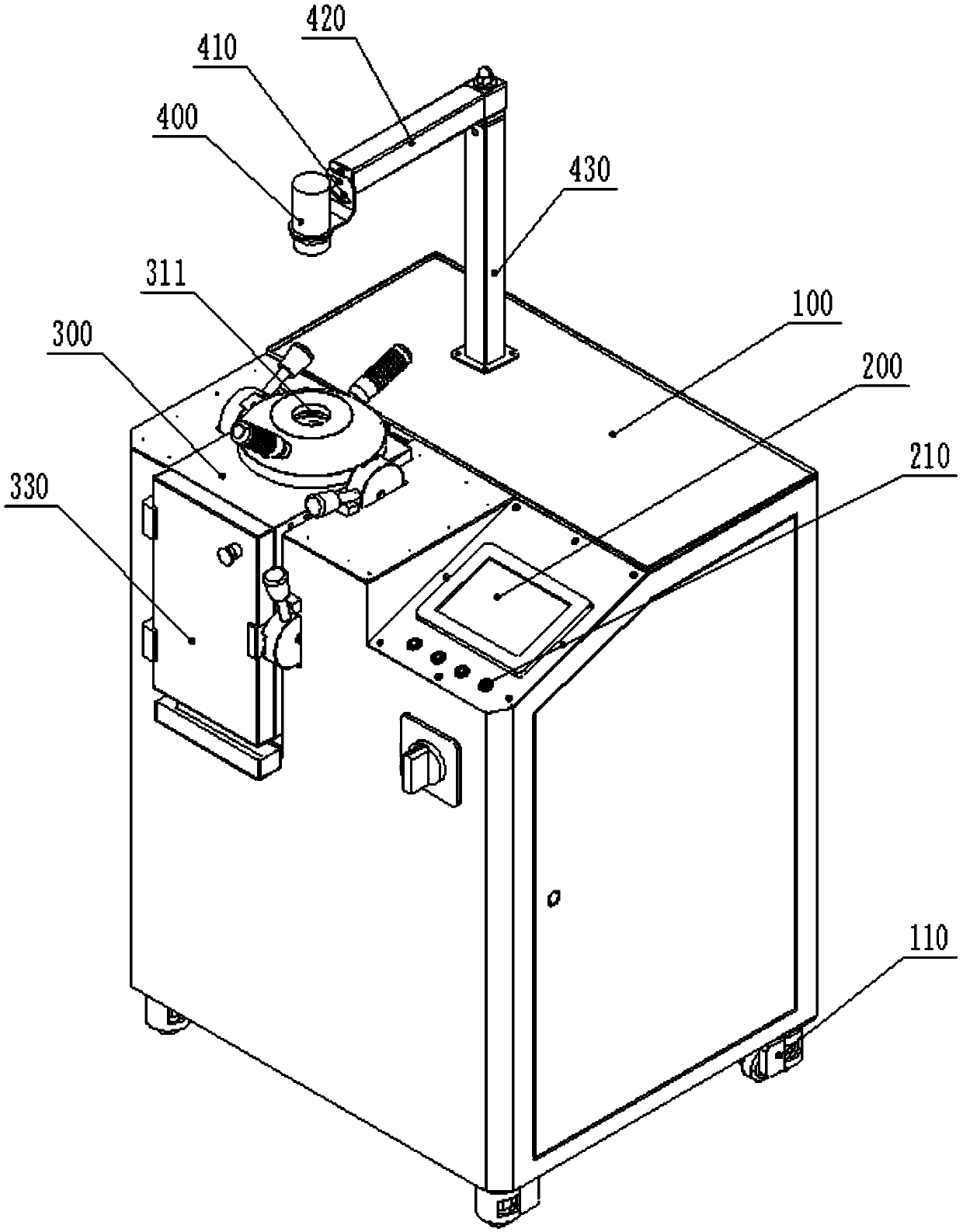

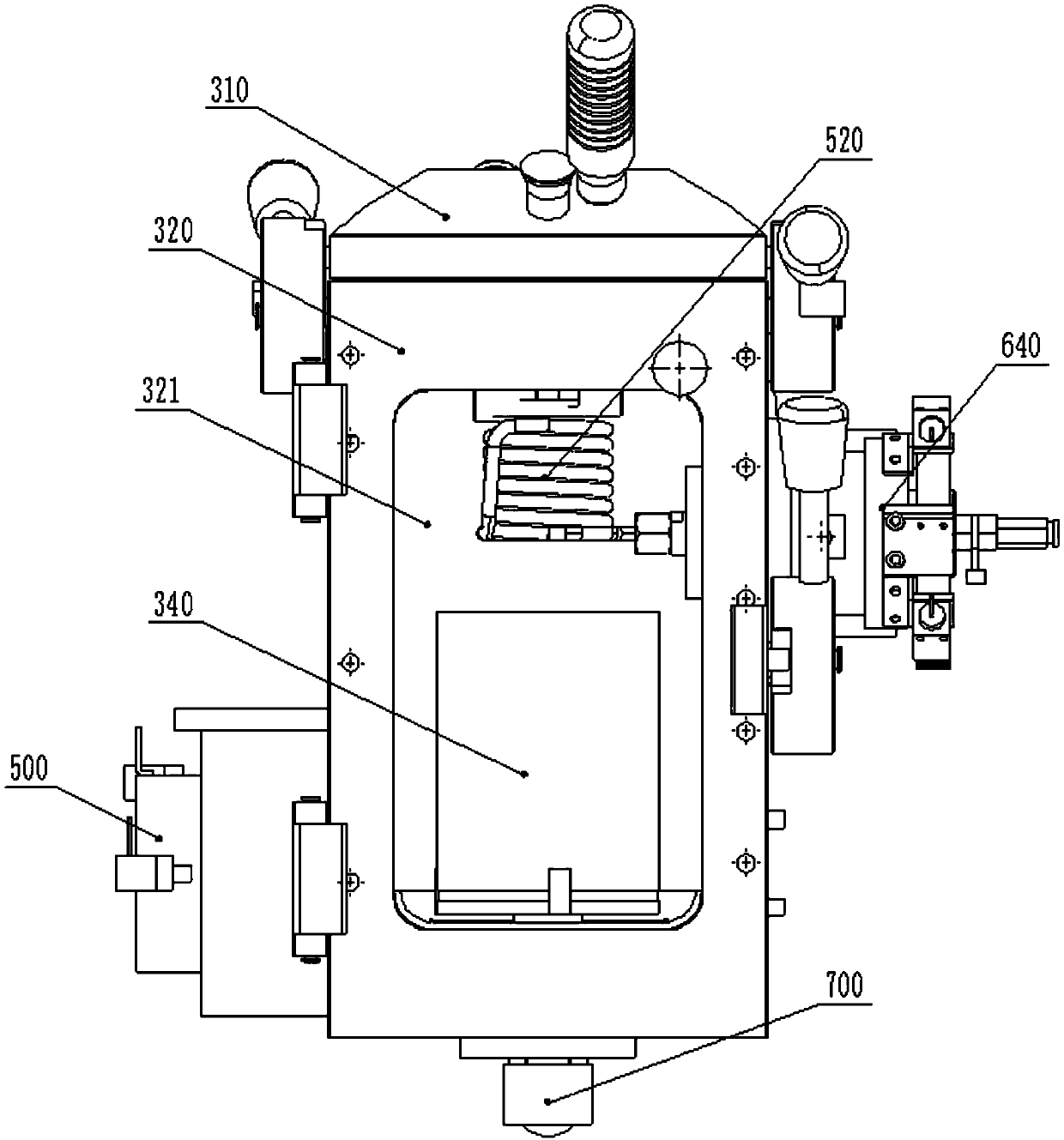

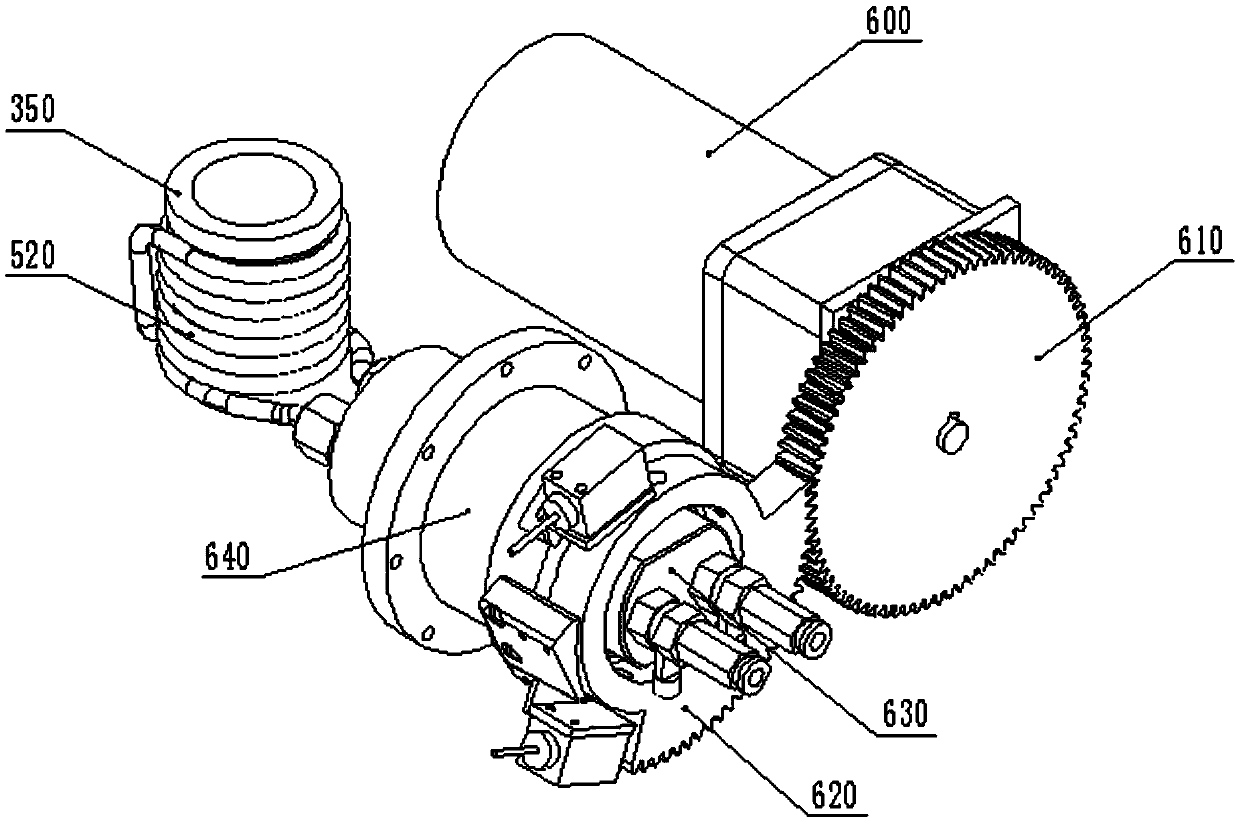

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , a centrifugal rotary casting machine with infrared temperature detection, comprising a chassis 100, a casting pot 300, a surrounding heating device, a crucible dumping device, a centrifugal rotating device, a cooling water circulation device, a vacuuming device, an air pressurizing device and an intelligent control system.

[0025] The casting pot 300 includes a pot body 320, a pot cover 310 and a revolving door 330, the pot cover 310 is hinged to the upper end of the pot body 320, and the pot cover 310 is provided with an observation window 311; the pot body 320 There is a steel cup take-out port 321 on one side, and the revolving door 330 is set in front of the steel cup take-out port 321 and is hinged to one side of the pot body 320; the casting pot 300 is provided with a melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com