Anti-cracking arc surface bendwood machine for rosewood bending

A technology of arc-shaped surface and explosion-proof cracking, which is applied in the direction of wood bending, wood processing equipment, manufacturing tools, etc., can solve the problems of insufficient molecular vibration of acid branch wood, incomplete softening of acid branch wood, cracks on the surface of acid branch wood, etc., to achieve Prevent water loss, improve softening effect, and prevent rapid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

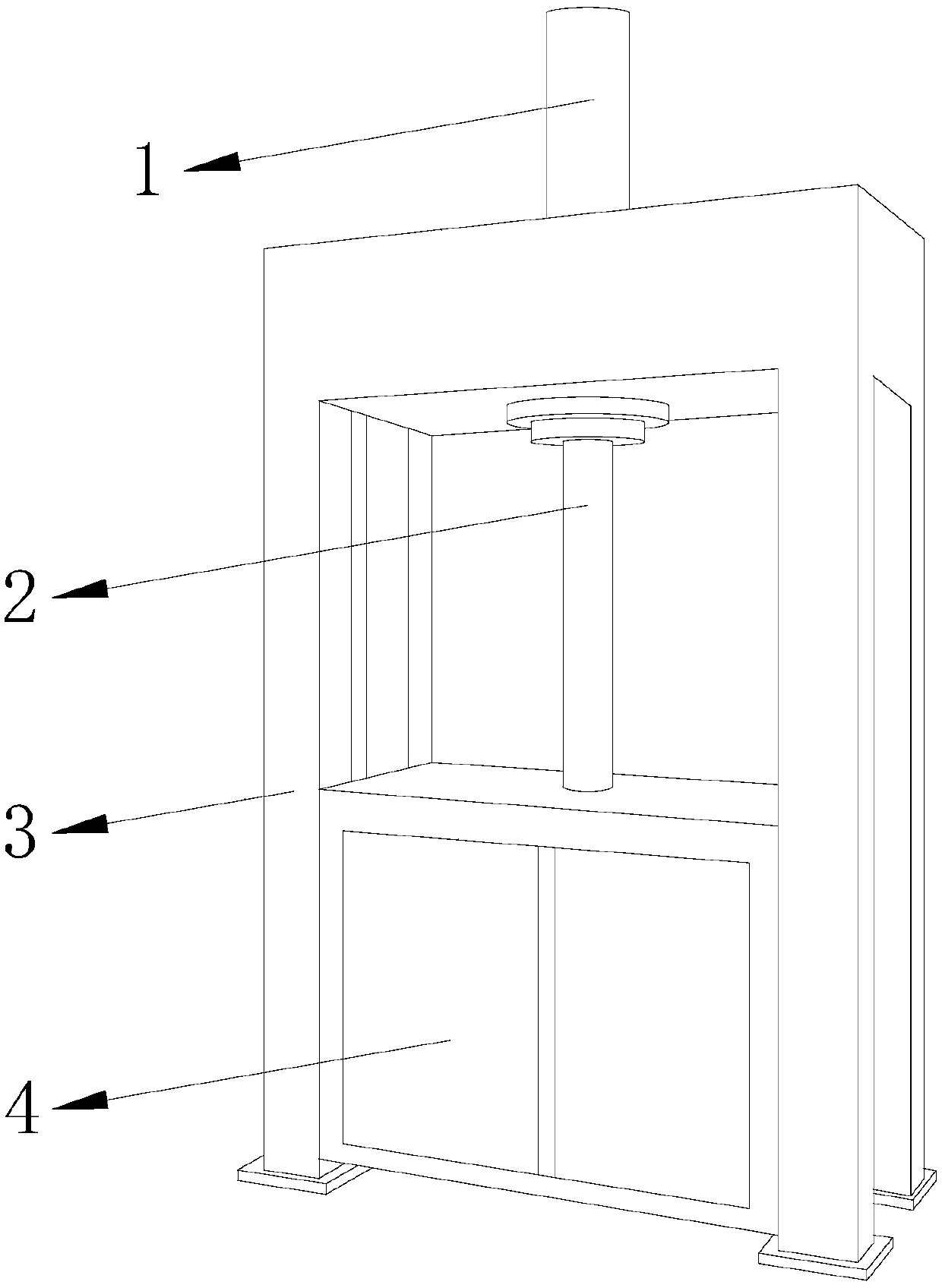

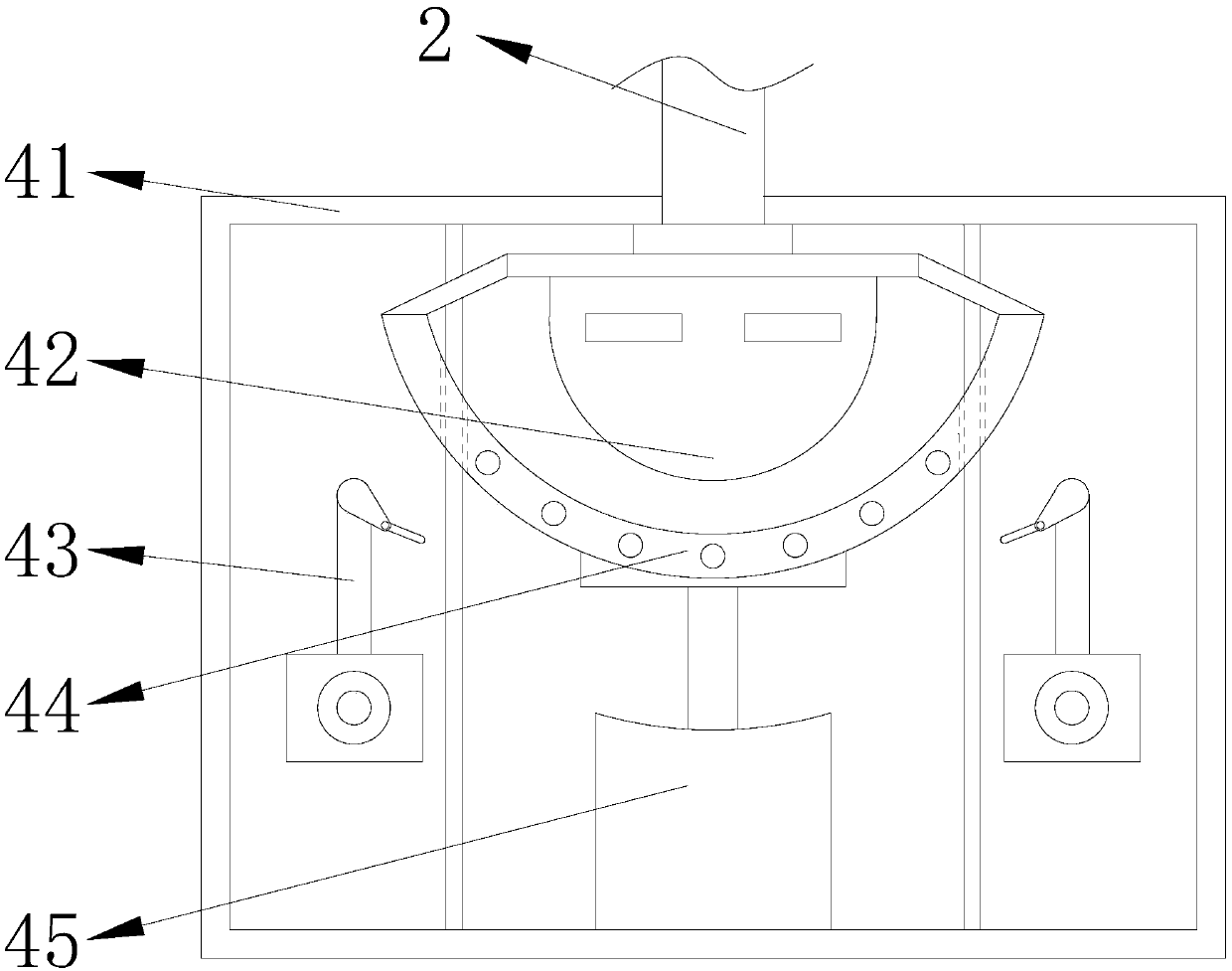

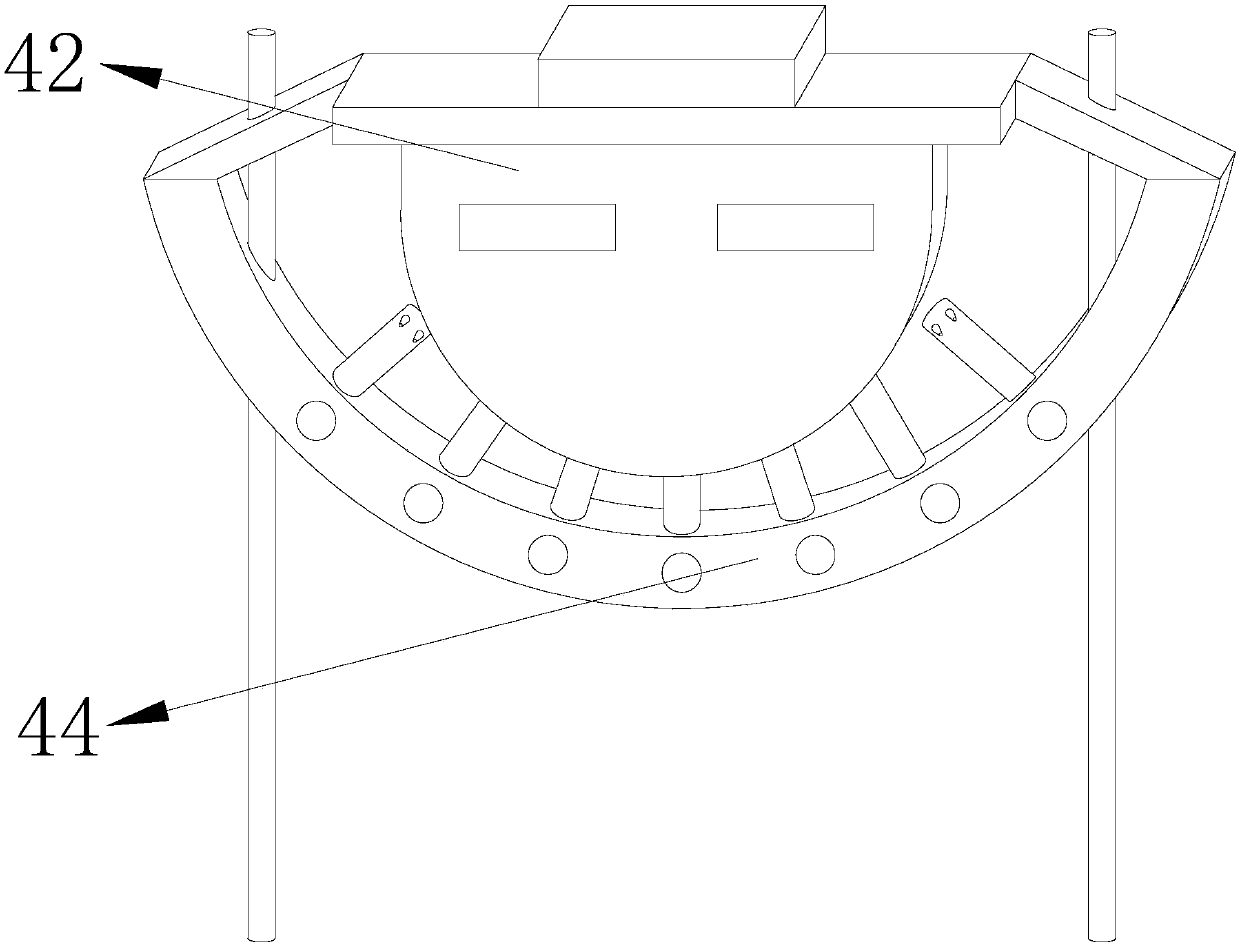

[0022] see Figure 1-Figure 9 , the present invention is an anti-explosion cracking arc surface bending machine for acid branch wood bending, its structure includes a pressing driver 1, a lifting connecting rod 2, a supporting main machine 3, and an explosion-proof cracking bent wood main machine 4, and the pressing driver 1 and The lifting connecting rod 2 is mechanically connected, the pressing driver 1 is fixedly installed on the top of the supporting host 3, the bottom end of the supporting host 3 is fixedly installed with an explosion-proof cracked wood host 4, and the lower end of the lifting connecting rod 2 is installed on the The inside of the explosion-proof cracked wood main unit 4 and adopt clearance fit, the explosion-proof cracked wood main unit 4 includes a protective shell 41, a metal barrel 42 pressed down on the circular arc surface, a fixer 43 at both ends of the wood, a pressurized spray mechanism 44, and a linkage molecule A vibrating mechanism 45, the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com