Imitation solid wood grain flotation printing process and device

A kind of wood and craftsmanship technology, which is applied in the field of imitation solid wood wood grain embossing technology and devices, which can solve the problems of reducing the use value of wood, the inability to position the wood grain, and the three-dimensional shape that cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

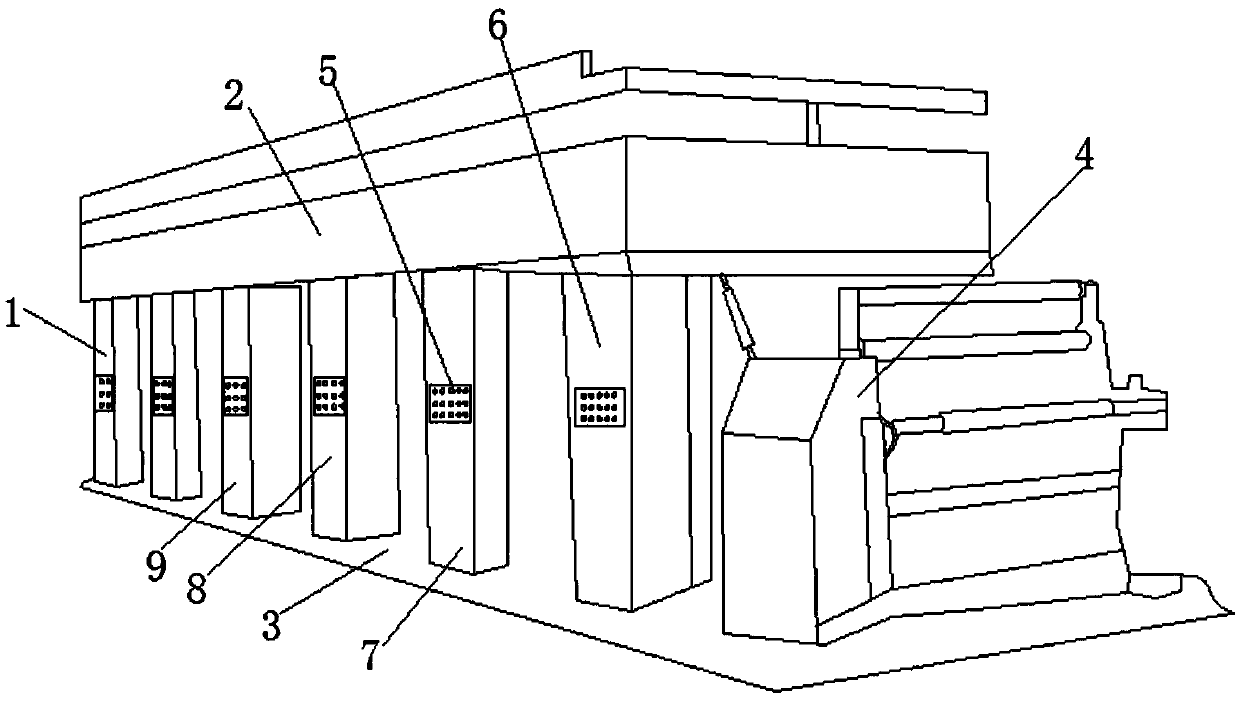

[0028] S1, for color matching, first put the corresponding toner into the fixed toner box 2 on the top of the printing machine 1;

[0029] S2, preheating, unwinding the raw material after preheating and entering the inside of the wood thorn front printing machine 6 for front printing; the preheating temperature is 40°C; the printing temperature is 25°C;

[0030] S3. Print the reverse side of the PVC film printed on the front side in S2; the printing temperature is 25°C;

[0031] S4, drying and rolling the PVC film that has been printed on the reverse side in S3; the temperature during drying and rolling is controlled at 50°C;

[0032] S5, the reverse side of the PVC film that has been dried and rolled up in S4 is printed with wood grain and bubble color; the printing temperature is 25°C;

[0033] S6, the PVC film that has been printed on the reverse side with wood grain bubble color in S5 is dried and rolled up again; the temperature during drying and rolled up is controlled ...

Embodiment 2

[0036] S1, for color matching, first put the corresponding toner into the fixed toner box 2 on the top of the printing machine 1;

[0037] S2, preheating, unwinding the raw material after preheating and entering the inside of the wood thorn front printing machine 6 for front printing; the preheating temperature is 45°C; the printing temperature is 25°C;

[0038] S3. Print the reverse side of the PVC film printed on the front side in S2; the printing temperature is 25°C;

[0039] S4, drying and rolling the PVC film that has been printed on the reverse side in S3; the temperature during drying and rolling is controlled at 50°C;

[0040] S5, the reverse side of the PVC film that has been dried and rolled up in S4 is printed with wood grain and bubble color; the printing temperature is 25°C;

[0041] S6, the PVC film that has been printed on the reverse side with wood grain bubble color in S5 is dried and rolled up again; the temperature during drying and rolled up is controlled ...

Embodiment 3

[0044] S1, for color matching, first put the corresponding toner into the fixed toner box 2 on the top of the printing machine 1;

[0045] S2, preheating, the raw material is unwound and then enters the inside of the wood thorn front printing machine 6 for front printing; the preheating temperature is 50°C; the printing temperature is 25°C;

[0046] S3. Print the reverse side of the PVC film printed on the front side in S2; the printing temperature is 25°C;

[0047] S4, drying and rolling the PVC film that has been printed on the reverse side in S3; the temperature during drying and rolling is controlled at 50°C;

[0048] S5, the reverse side of the PVC film that has been dried and rolled up in S4 is printed with wood grain and bubble color; the printing temperature is 25°C;

[0049] S6, the PVC film that has been printed on the reverse side with wood grain bubble color in S5 is dried and rolled up again; the temperature during drying and rolled up is controlled at 50°C;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com