A method for reusing waste water in magnetic material industry

A technology for industrial wastewater and magnetic materials, applied in ceramic wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as non-compliance with the water requirements of permanent ferrite manufacturers, poor pH value and water quality activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

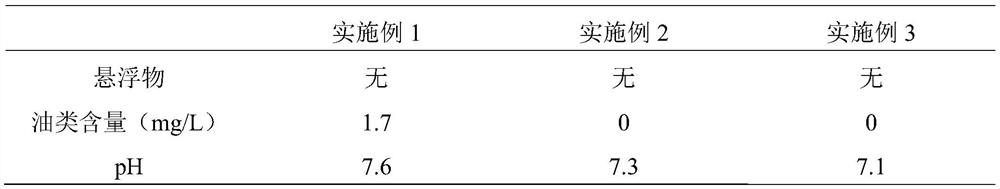

Embodiment 1

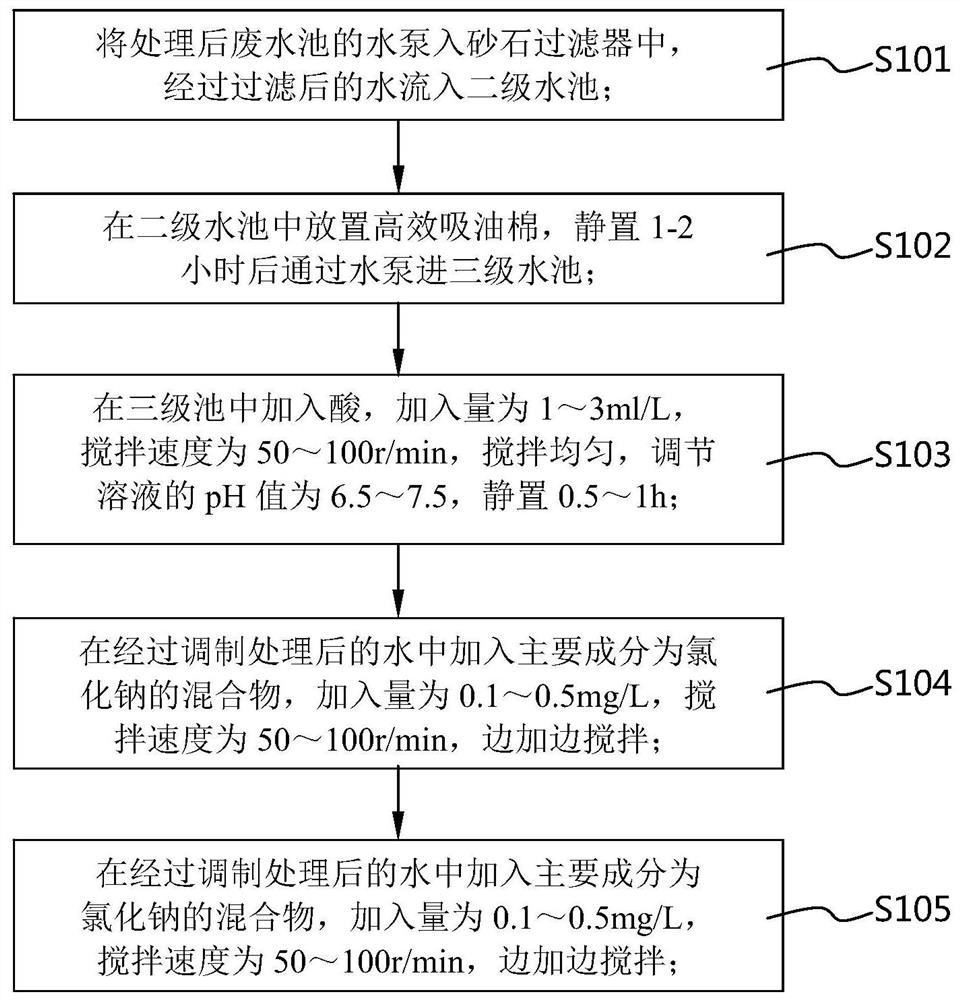

[0052] A method for treating emulsion wastewater in the magnetic material industry, the specific process is shown in figure 1 , follow the steps below:

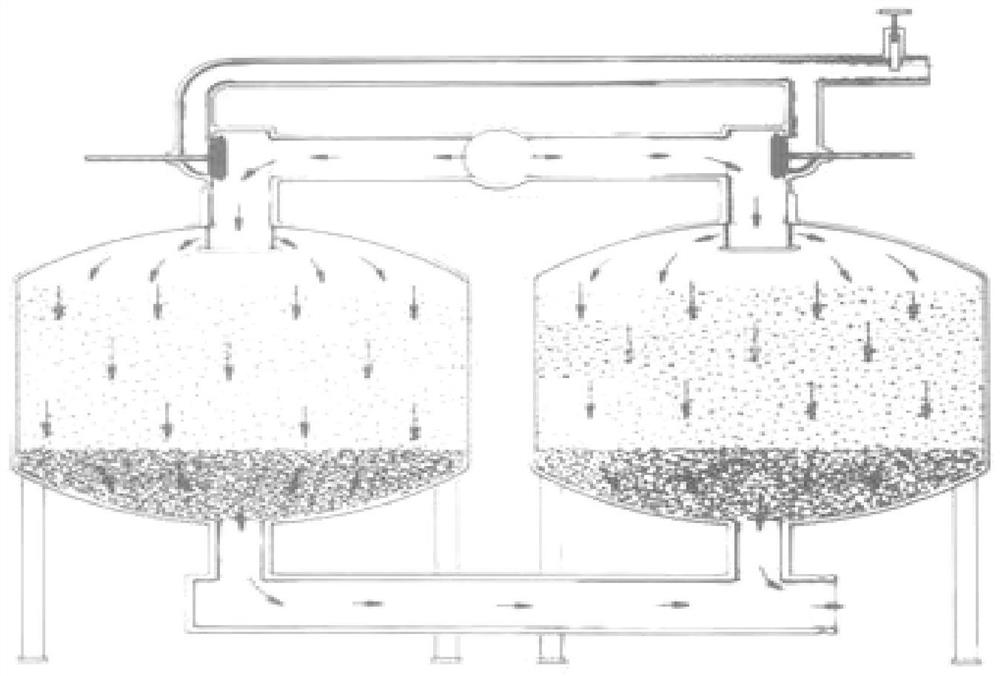

[0053] (1) The first step of filtration: pump the water from the treated wastewater pool (primary pool) into the gravel filter, and the filtered water flows into the secondary pool;

[0054] (2) The second step of oil absorption: place high-efficiency oil-absorbing cotton in the secondary pool, and after standing for 1 hour, pump it into the next pool (tertiary pool);

[0055] (3) The third step of preparation: add acetic acid with a concentration of 36% in the three-stage pool, the addition amount is 1ml / L, the stirring speed is 50r / min, stir evenly, adjust the pH value of the solution to 7.6, and let it stand for 0.5h ;

[0056] (4) The third step of salinization: add sodium chloride to the prepared water, the addition amount is 0.2mg / L, the stirring speed is 50r / min, and stir while adding;

[0057] (5) The water after t...

Embodiment 2

[0060] A method for treating emulsion wastewater in the magnetic material industry is specifically carried out according to the following steps:

[0061] (1) The first step of filtration: pump the water from the treated wastewater pool (primary pool) into the gravel filter, and the filtered water flows into the secondary pool;

[0062] (2) The second step of oil absorption: place high-efficiency oil-absorbing cotton in the secondary pool, let it stand for 1.5 hours, and then pump it into the next pool (tertiary pool);

[0063] (3) The third step of preparation: add acetic acid with a concentration of 37% in the three-stage pool, the addition amount is 2ml / L, the stirring speed is 70r / min, stir evenly, adjust the pH value of the solution to 7.3, and let it stand for 0.75h ;

[0064] (4) The third step of salinization: add sodium chloride to the prepared water, the addition amount is 0.4mg / L, the stirring speed is 70r / min, and stir while adding;

[0065] (5) The water after th...

Embodiment 3

[0068] A method for treating emulsion wastewater in the magnetic material industry is specifically carried out according to the following steps:

[0069] (1) The first step of filtration: pump the water from the treated wastewater pool (primary pool) into the gravel filter, and the filtered water flows into the secondary pool;

[0070] (2) The second step of oil absorption: place high-efficiency oil-absorbing cotton in the secondary pool, and after standing for 2 hours, pump it into the next pool (tertiary pool);

[0071] (3) The third step of preparation: add acetic acid with a concentration of 38% in the third-stage pool, the addition amount is 3ml / L, the stirring speed is 100r / min, stir evenly, adjust the pH value of the solution to 7.1, and let it stand for 1h;

[0072] (4) The third step of salinization: add sodium chloride to the prepared water, the addition amount is 0.5mg / L, the stirring speed is 100r / min, and stir while adding;

[0073] (5) The water after the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com