Method and apparatus for treating oily sludge

A treatment method and technology of a treatment device, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of non-reusable wastewater, short process flow, and insufficient sludge treatment. Reach the standard and other issues to achieve the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

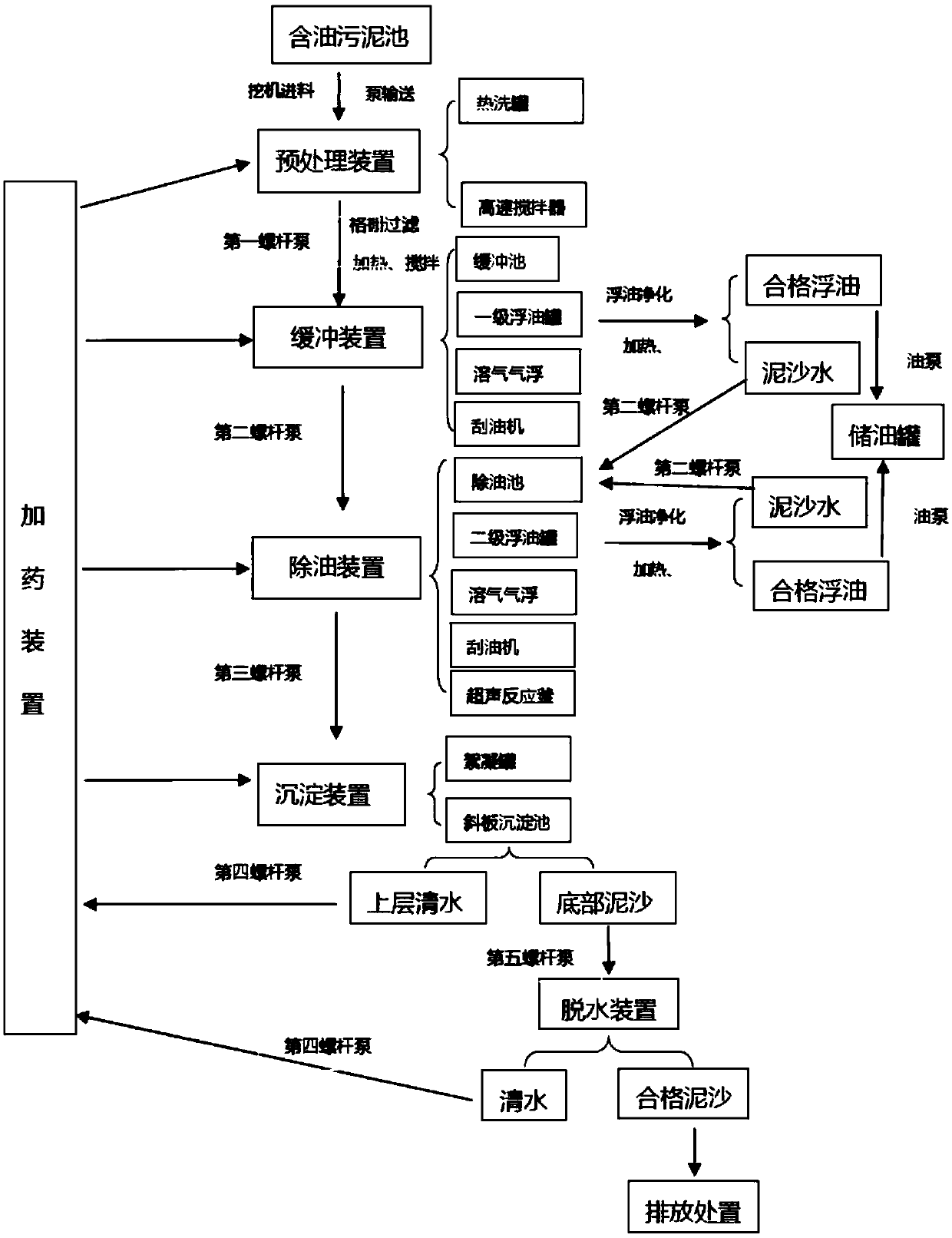

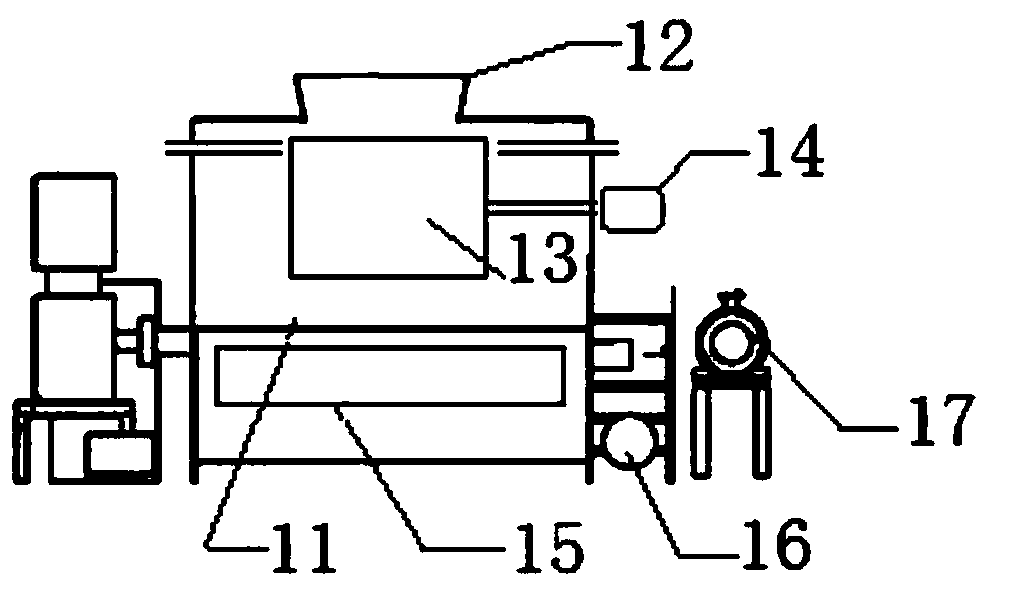

[0052] Such as figure 1 In the example of the present invention, a kind of processing method of oily sludge of the present invention mainly comprises the following steps:

[0053] 1) Remove impurities, add medicament and water, stir and mix for demulsification;

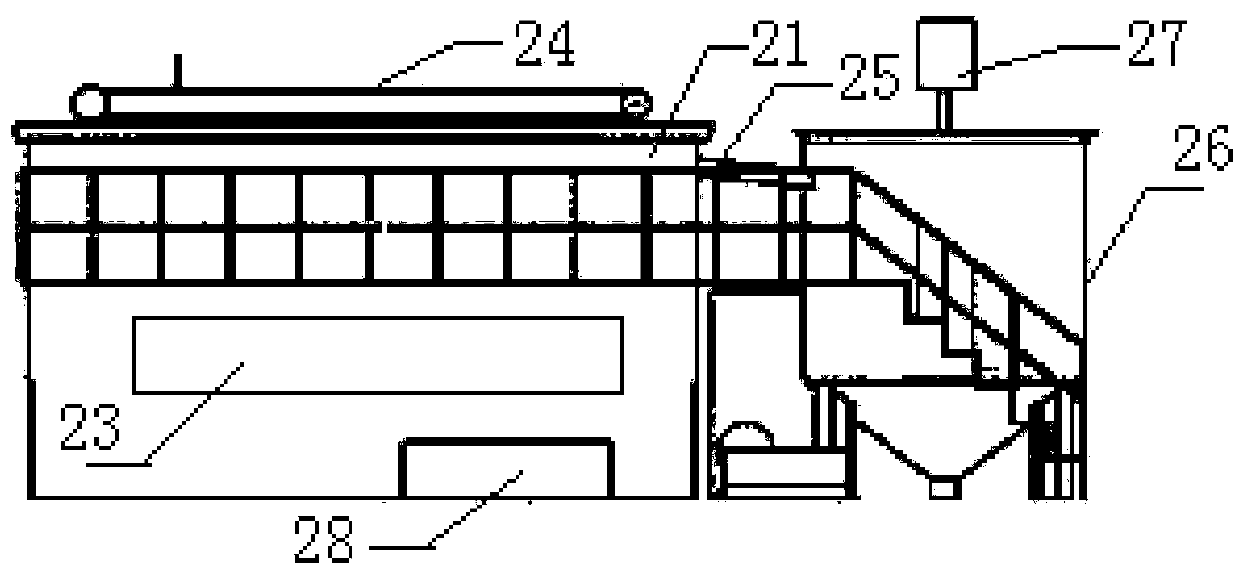

[0054] 2) Under the condition of horizontal stirring in the mixed solution obtained in step 1), the oil phase is initially recovered by dissolved air flotation;

[0055] 3) The mixed solution obtained in step 2) is oxidized by ultrasonic and ozone, and the residual oil phase is recovered again, and the sludge is initially concentrated and dehydrated by flocculation and precipitation;

[0056] 4) The supernatant obtained in step 3) is recovered, and the sludge is dehydrated again by a dehydrator to complete the treatment, and the water produced by the dehydrator is recovered, and the water extracted twice is reused for dispensing to realize recycling.

[0057] Specifically, the concrete process route among the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com