Manufacturing process of 3D glass cover plate

A technology of glass cover plate and manufacturing process, which is applied in glass forming, glass manufacturing equipment, glass reshaping, etc. It can solve the problems of serious homogeneity, lack of novelty, and difficulty in meeting the high-quality appearance requirements of products. Achieve low manufacturing cost, meet appearance requirements, and meet high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

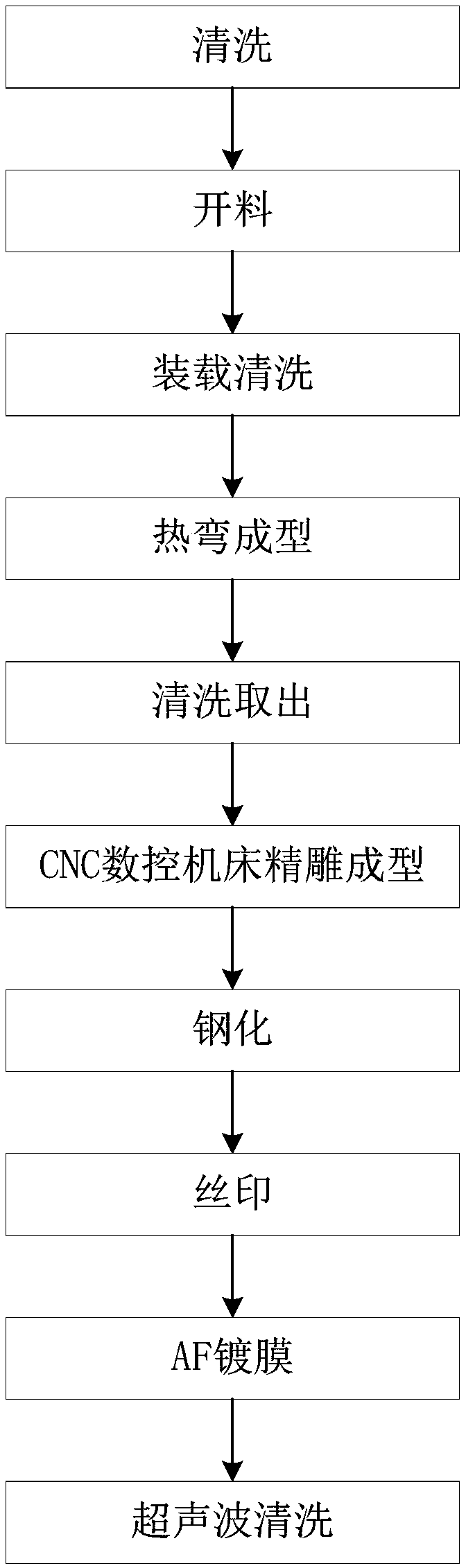

[0031] figure 1 It shows a flow chart of a manufacturing process of a 3D glass cover provided by an embodiment of the present invention, which is detailed as follows:

[0032] (1) Cleaning: Use high-pressure air flow or high-pressure water flow to clean and dry the surface of the raw glass for standby;

[0033] (2) Cutting: cutting the cleaned and dried raw glass into multiple glass sheets of the required appearance size;

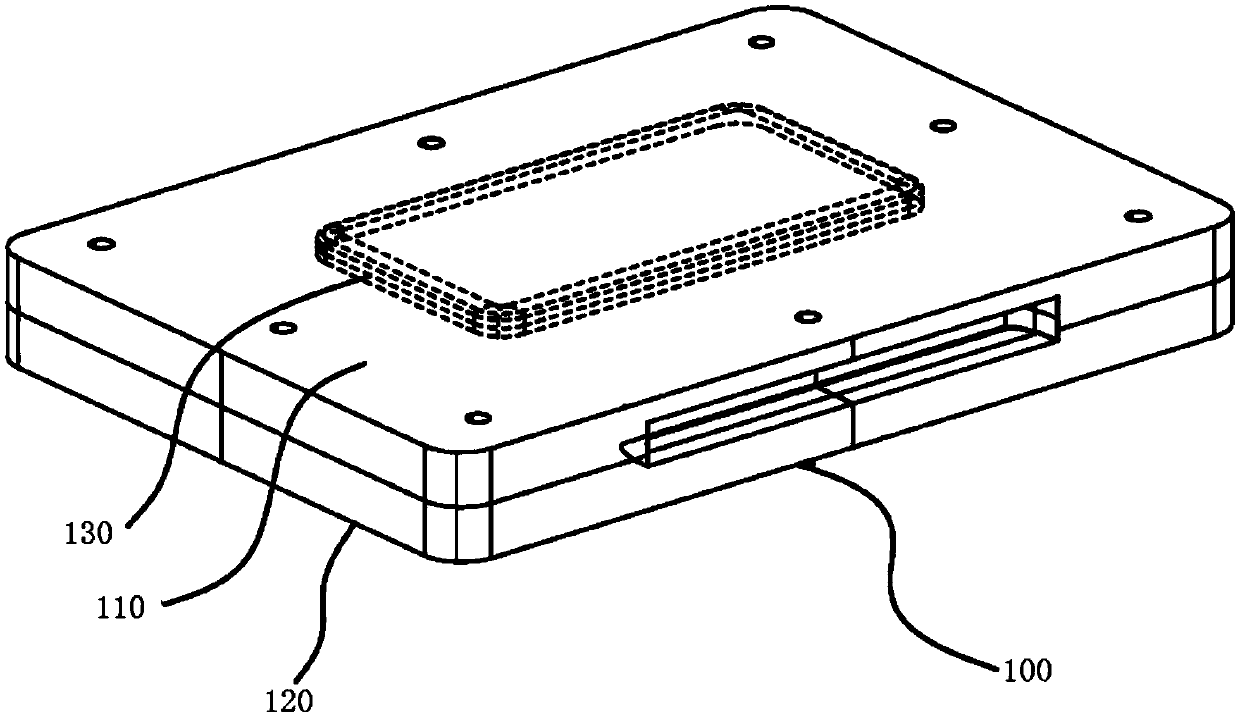

[0034] (3) Loading and cleaning: Use high-pressure airflow or high-pressure water flow to clean the surface of the glass sheet, and then set up a mold 100, such as figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com