Single-component polyurethane adhesive and preparation method and application thereof

A polyurethane adhesive, one-component technology, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

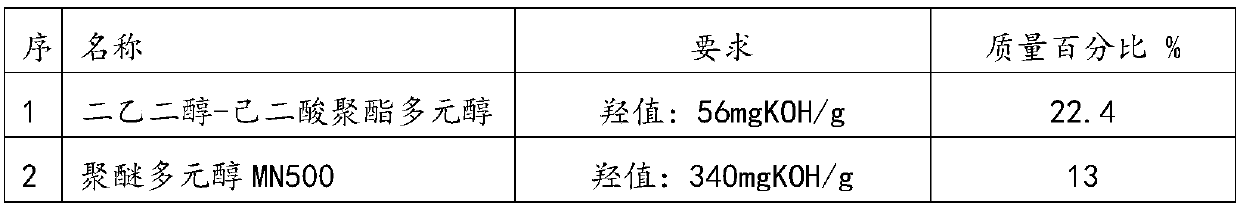

[0043] In this example, the preparation process of the one-component polyurethane adhesive material of the present invention is described in detail. The preparation process includes the following steps: 1) ingredient list and performance; 2) production process; the above-mentioned two steps will be described in detail below .

[0044] 1) Ingredients and performance table

[0045] Ingredients list and ingredients basic data

[0046]

[0047]

[0048] 2) Production process

[0049] (1) Add polyester polyol, polyether polyol, ethyl acetate and KH560 into the reaction kettle in sequence according to the proportion. Start the stirrer and keep it at 300 rpm for 30 minutes.

[0050] (2) Add MDI-100, raise the temperature to 50°C within 1 hour, and dissolve it completely.

[0051] (3) Gradually raise the temperature to 70-80°C. After reacting for 1 hour, check the NCO% every half hour. When it reaches 2.3-2.6%, the reaction can be considered complete;

[0052] (4) Cool down...

example 2

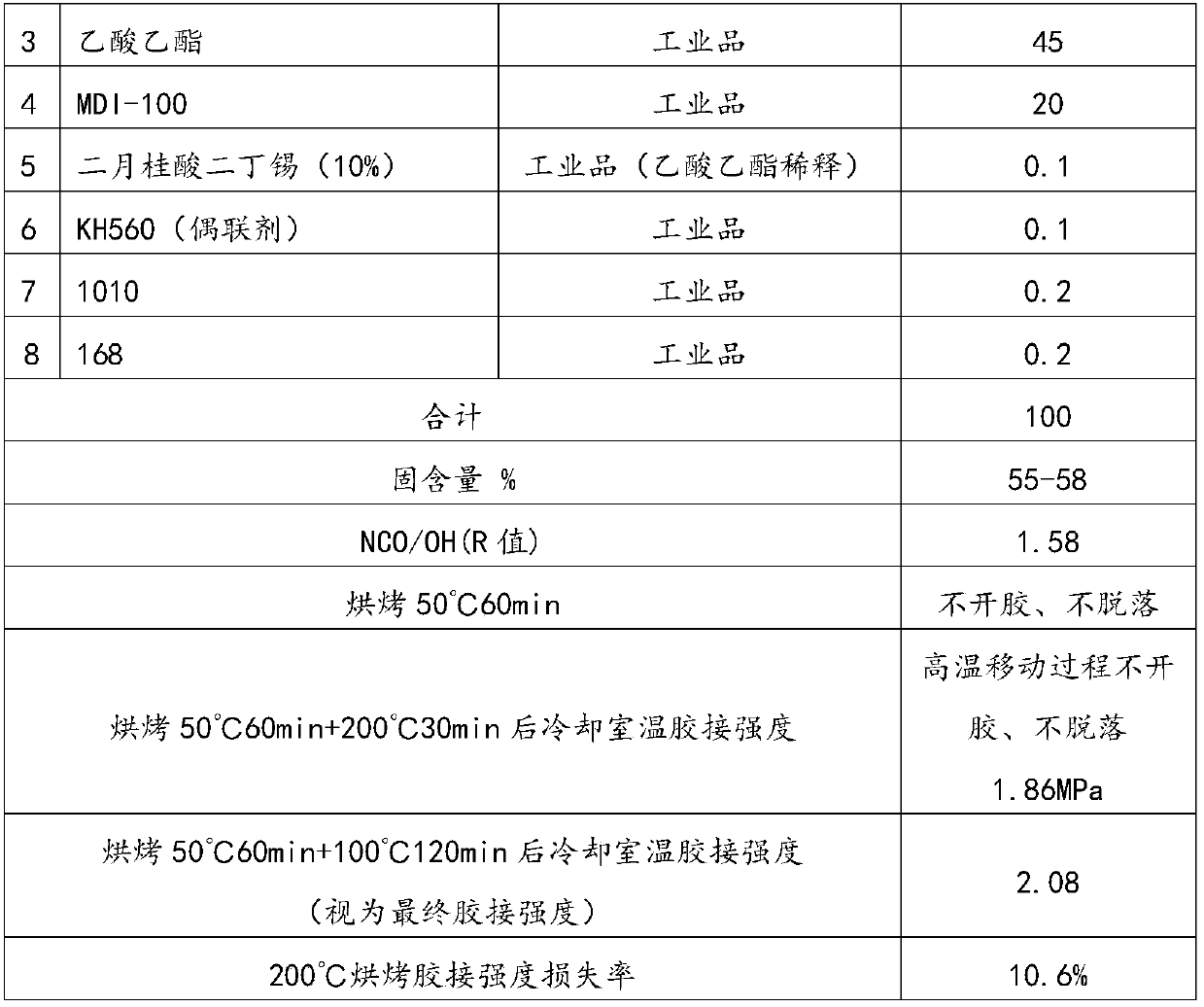

[0054] It can be seen that although Example 1 can meet the requirements of mechanical properties, does not break off, does not fall off, and the production process is relatively simple (MDI-100 is not sealed), but the overall bonding strength is low. Due to the high dosage and high price of MDI-100, Instance 1 has a higher overall price. Therefore, in this example, PAPI is used to enhance the overall functionality, and a closed method is used to reduce the risk of curing and gelling. The preparation process includes the following steps: 0) PAPI sealing; 1) ingredient list and performance; 2) production process;

[0055] The above three steps will be described in detail below.

[0056] 1) Ingredients list

[0057] Ingredients list and ingredients basic data

[0058]

[0059] 2) Production process

[0060] (0) PAPI sealing: Mix ethyl acetate and PAPI evenly at a weight ratio of 1:1, add phenol (phenol: PAPI weight ratio is 7:100), gradually raise the temperature to 60-80°...

example 3

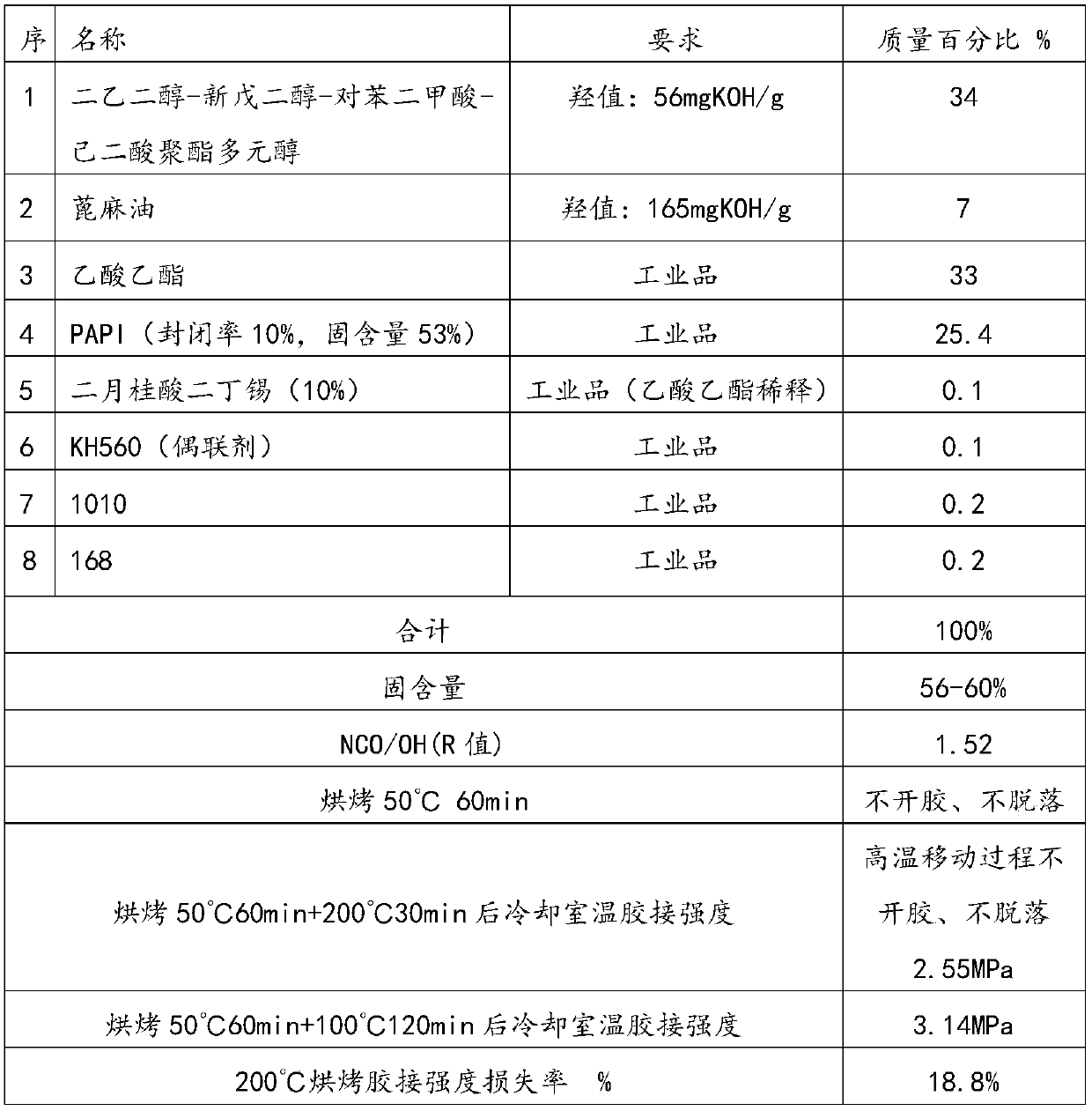

[0066] In this example, castor oil is used, and the technology of closed NCO% is used to achieve the bonding strength after baking at a high temperature of 200°C for 30 minutes to reach more than 2MPa, but the process is more complicated and the cost is higher. The preparation process includes the following steps: 0) pretreatment; 1) ingredient list; 2) production process; the above three steps will be described in detail below.

[0067] 1) Ingredients list

[0068] Ingredients list and ingredients basic data

[0069]

[0070] 2) Production process

[0071] (0) PAPI sealing: Mix ethyl acetate and PAPI evenly at a weight ratio of 1:1, add phenol (phenol: PAPI weight ratio is 7:100), gradually raise the temperature to 60-80°C, and wait until the phenol is completely dissolved. Detect the NCO% content every 1 hour, and if the detection reaches 13.7-13.8%, it is qualified, and the material is discharged for standby.

[0072] (1) Add polyester polyol, polyether polyol, ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com