A method for one-step comprehensive recovery of NdFeB waste flash roasting

A flash roasting and NdFeB technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficult comprehensive utilization of leaching slag, inaccurate control of temperature and atmosphere, and decreased total recovery rate of rare earths, so as to achieve convenient and comprehensive utilization of iron resources , superior reaction kinetics conditions, and the effect of improving the total recovery rate of rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

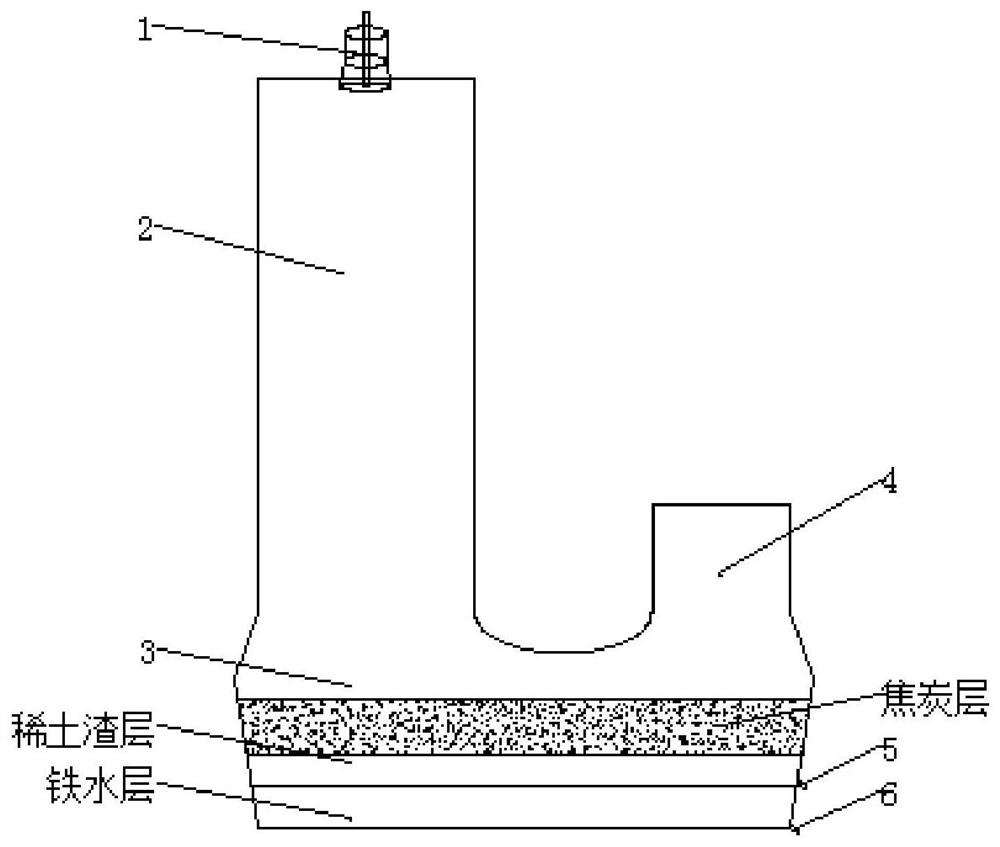

[0018] Embodiment 1: be the SiO of 80 purpose powdery neodymium-iron-boron waste materials and waste material weight 5% with particle size 2 After the powder is mixed, it is sprayed from the nozzle (1) into a reaction tower (2) with a height of 2.5 meters and a temperature of 1200°C together with a mixed gas of nitrogen and oxygen (oxygen content 50%). The material is highly dispersed and floats from the reaction tower. The upper end of the tower falls to the lower end, during this process, the oxygen partial pressure in the reaction tower is controlled to be 10 -20 Atm, the rare earth in the material is rapidly oxidized by oxygen-enriched air, the oxidation rate is 99.24%, 78% of the iron in the waste is not oxidized, 15% of the iron is oxidized into triiron tetroxide, and 7% of the iron is oxidized into trioxide Second iron. When the roasted product falls to the sedimentation tank (3) below the reaction tower, it passes through the hot coke layer at 1350°C above the sedimen...

Embodiment 2

[0020] After mixing the powdered NdFeB waste with a particle size of 100 mesh and CaO powder with a weight of 6% of the waste, it is sprayed together with a mixed gas of nitrogen and oxygen (oxygen content 95%) into a nozzle (1) with a height of 3.5 meters and a temperature of It is a reaction tower (2) at 1350°C. The material is highly dispersed and floats from the upper end of the reaction tower to the lower end. During this process, the oxygen partial pressure in the reaction tower is controlled to be 10 -15 Atm, the rare earth in the material is rapidly oxidized by oxygen-enriched air, and the oxidation rate is 99.65%. 71% of the iron in the waste is not oxidized, 18% of the iron is oxidized into triiron tetroxide, and 11% of the iron is oxidized into trioxide Second iron. When the roasted product falls to the sedimentation tank (3) below the reaction tower, it passes through the hot coke layer at 1450°C above the sedimentation tank, and ferric oxide and ferric oxide are r...

Embodiment 3

[0022] Be that the particle size is 200 mesh powdery neodymium-iron-boron waste materials and the SiO of waste material weight 3% 2 powder, 2% CaO powder, mixed with argon and oxygen mixed gas (oxygen content 65%) into a reaction tower (2) with a height of 5.5 meters and a temperature of 1500 ° C through a nozzle (1). Highly dispersed in a floating state from the upper end of the reaction tower to the lower end, during this process, the partial pressure of oxygen in the reaction tower is controlled to be 10 -10 Atm, the rare earth in the material is rapidly oxidized by oxygen-enriched air, the oxidation rate is 99.86%, 67% of the iron in the waste is not oxidized, 21% of the iron is oxidized into ferric oxide, and 12% of the iron is oxidized into trioxide Second iron. When the roasted product falls to the sedimentation tank (3) below the reaction tower, it passes through the hot coke layer at 1550°C above the sedimentation tank, and ferric oxide and ferric oxide are reduced t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com