Waste steel slag permeable base layer and laying method thereof

A technology of permeable base and permeable layer, which is applied to pavement details, roads, gutters/curbs, etc. It can solve the problems of low stability of sand cushion, blocking rainwater infiltration, and settlement of permeable bricks, etc., achieving simple laying, Energy saving and easy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

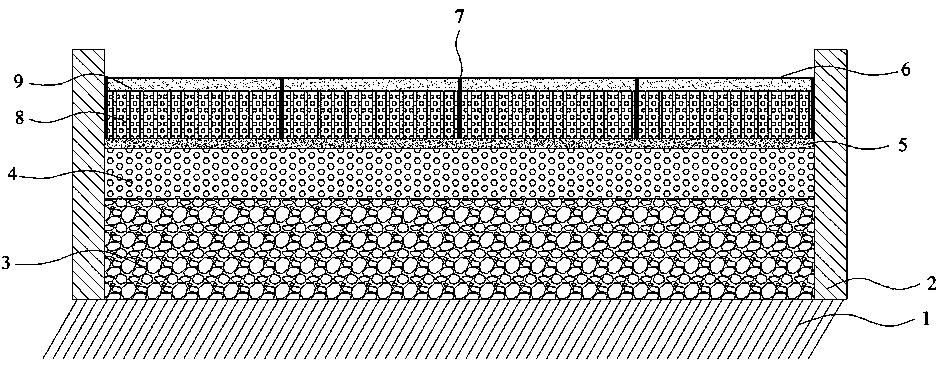

[0025] Such as figure 1 As shown, a waste steel slag permeable base layer includes a base layer 1, a curb 2, a crushed stone stabilization layer 3, a permeable concrete layer 4, a leveling layer 5, and a permeable brick 6. The base layer 1 is a cleaned road. Curb stones 2 are arranged on both sides of the base layer 1, the gravel stabilizing layer 3 is evenly laid between the curb stones 2 on the base layer 1, and the permeable concrete layer 4 is laid on the gravel stabilizing layer. On layer 3, the permeable concrete layer 4 is a permeable concrete structure with pores inside, the leveling layer 5 is laid on the permeable concrete layer 4, and the material of the leveling layer 5 includes waste steel slag and cement, The permeable brick 6 is laid on the leveling layer 5, the permeable bricks 6 are connected by a fine sand layer 7, and the fine sand layer 7 connects the permeable brick 6 and the curb stone 2. The permeable brick 6 includes a bottom water permeable layer 8 and...

Embodiment 2

[0038] Such as figure 1 As shown, a water-permeable base layer of scrap steel slag has a structure as described in Example 1.

[0039] A method for laying a permeable base layer of waste steel slag includes the following steps:

[0040] Step 1. Preparation before laying: clean the surface of the base layer 1 where the permeable base layer is to be laid, and set curbs 2 on both sides of the base layer 1;

[0041] Step 2. Laying the crushed stone stabilizing layer 3: The crushed stone stabilizing layer 3 is made of crushed stones with a particle size of 5-20 mm, and they are evenly laid on the surface of the base layer 1 cleaned in the step 1, and the surface is poured after laying. Water to wet the surface of the crushed stone stabilizing layer 3, and the thickness of the crushed stone stabilizing layer 3 is preferably 35 cm;

[0042] Step 3. Laying the permeable concrete layer 4: The permeable concrete layer 4 is a concrete structure with pores and permeable inside, and is evenly lai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com