System and method for engine oil temperature estimation

A technology of engine and engine speed, applied in the direction of engine lubrication, engine components, combustion engine, etc., can solve the problems of engine component deterioration, suboptimal engine performance, engine life reduction, etc., to reduce the need and improve the accuracy of torque estimation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

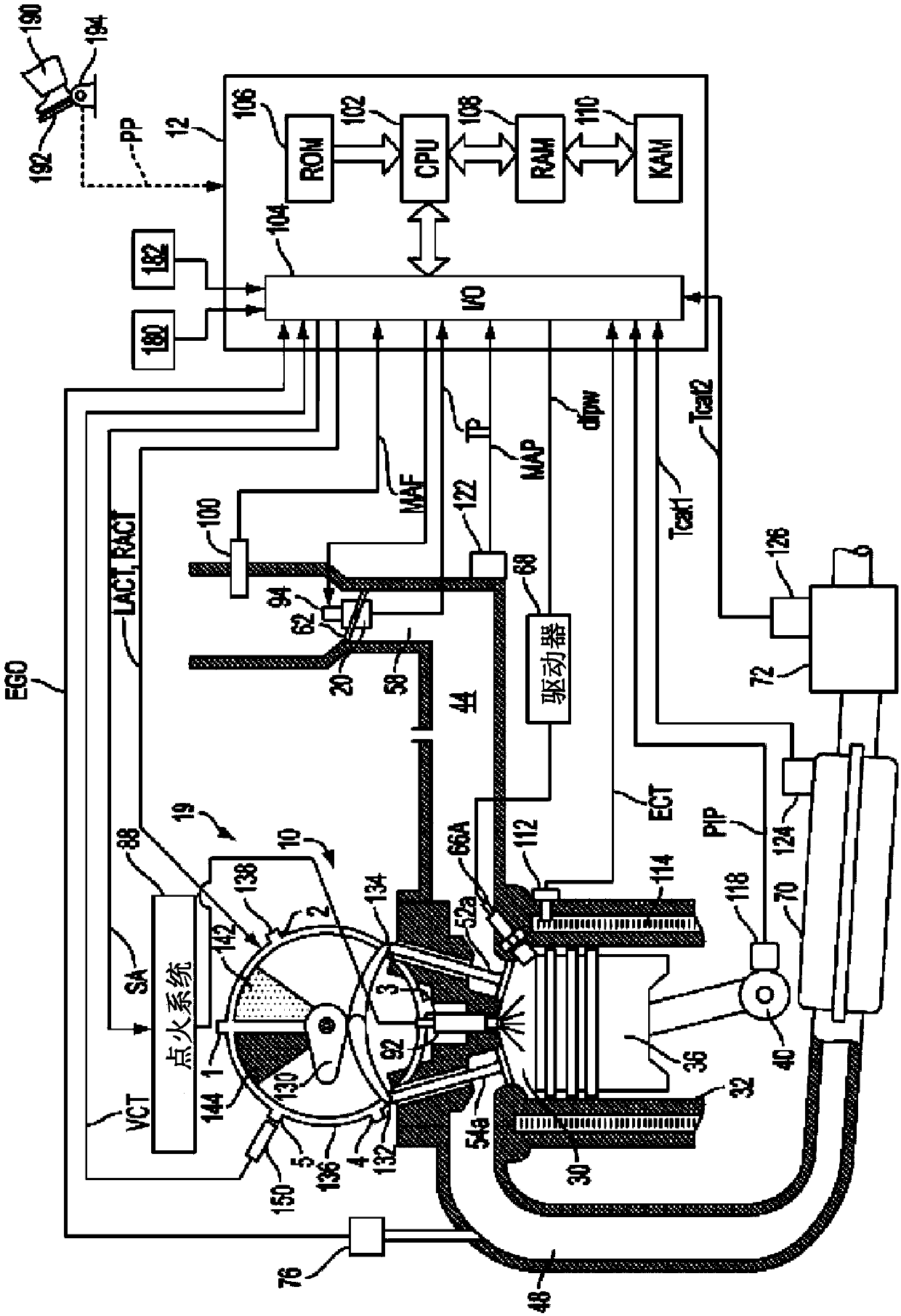

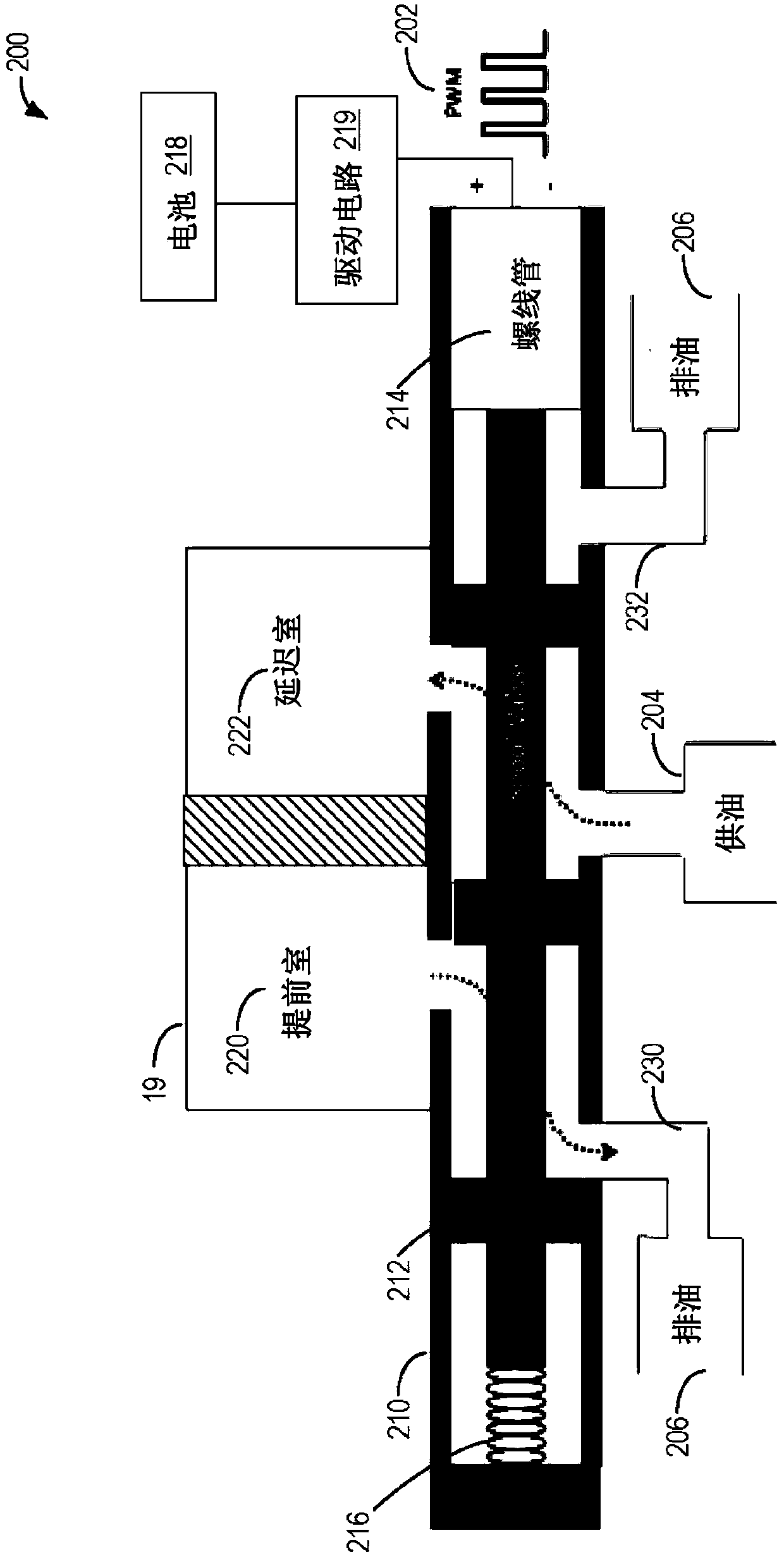

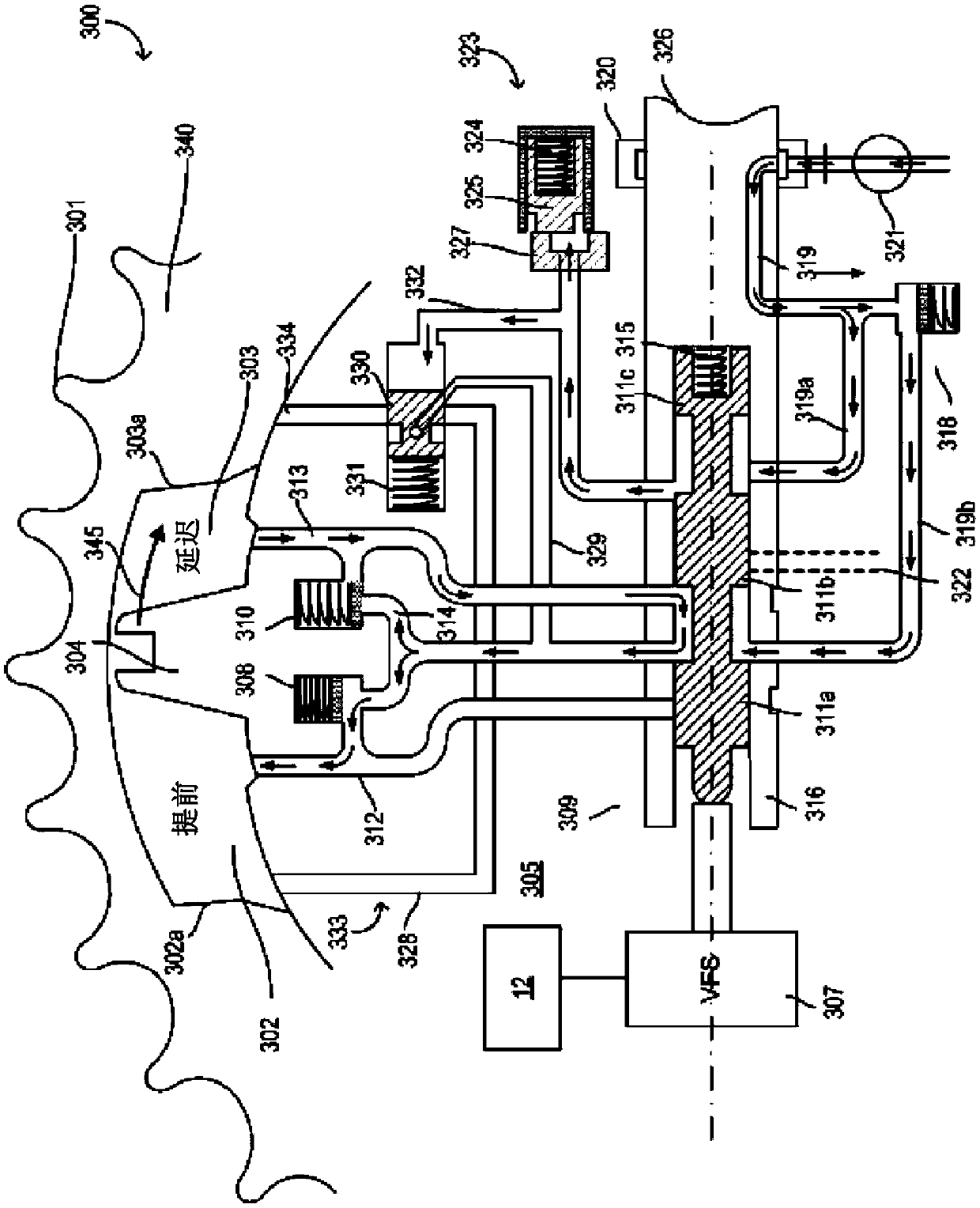

[0016] The following description relates to systems and methods for controlling a vehicle engine having a variable cam timing (VCT) device actuated using oil pressure via an oil control valve, such as Figure 1-2 shown. The engine controller can be configured to execute control routines such as Figure 4 ) to estimate engine oil temperature (EOT) under conditions where the default EOT estimation method is unreliable, such as due to sensor degradation or due to unreliable sensor output. The controller can apply a pulse width signal to know the zero duty cycle of the oil control valve ( Figure 5 ) and then based on the mapping relationship between VCT duty cycle and EOT ( Image 6 ) to infer EOT. refer to Figure 7-10 The example of shows an exemplary EOT estimation.

[0017] figure 1 An exemplary embodiment of a combustion chamber or cylinder of internal combustion engine 10 is depicted. figure 1 It is shown that engine 10 may receive control parameters from a control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com