Forced cooling system for wind turbine unit pitch control cabinet

A wind turbine and forced cooling technology, which is applied to wind engines, engines, wind power generation, etc., can solve the problems of low cooling efficiency and achieve the effects of improving cooling efficiency, improving heat dissipation efficiency, and low energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

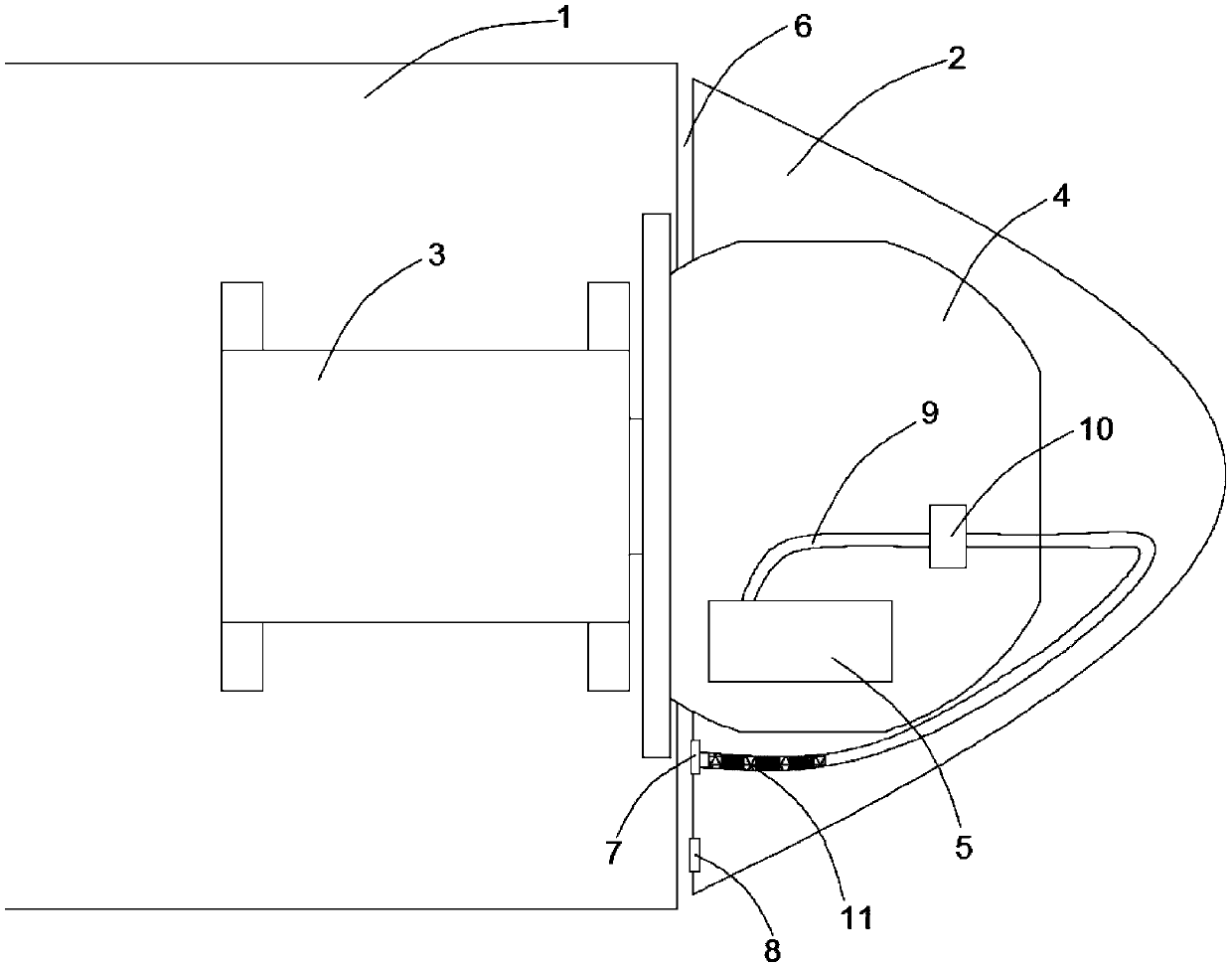

[0021] Such as figure 1 As shown, this embodiment provides a forced cooling system for a pitch control cabinet of a wind turbine, including a wind turbine and a pitch control device, and the wind turbine includes a nacelle 1 and a shroud 2 arranged on the top of the nacelle 1, and The control system includes a pitch control cabinet 5. A main shaft 3 is arranged inside the nacelle 1. The top of the main shaft 3 is connected with a hub 4 arranged inside the spinner 2. The pitch control cabinet 5 is arranged inside the hub 4. The spinner 2 and the nacelle There is a gap 6 of 3cm to 7cm between 1, the gap 6 directly communicates with the outside world, the side of the hub 4 in the gap 6 is provided with an air inlet 7 and a pressure-reducing port 8, and the air inlet 7 is connected to the air guide cover 2 The air inlet pipe 9 directly communicates with the pitch control cabinet 5, and the air inlet pipe 9 is provided with a blower fan 10.

[0022] Through the gap between the air...

Embodiment 2

[0024] Such as figure 1 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0025] There is a gap 6 of 5 cm between the wind deflector 2 and the nacelle 1 .

[0026] The outer diameter of the nacelle 1 is 5 cm to 7 cm larger than the outer diameter of the bottom surface of the wind deflector 2 .

[0027] The outer diameter of the nacelle 1 is slightly larger than the outer diameter of the bottom surface of the shroud 2, so that the external air flow can be blocked by the shunt of the shroud 2, and more cold air can enter the gap 6, so that the fan 10 can more easily suck in the outside air, reducing Energy consumption, improve practicality.

Embodiment 3

[0029] Such as figure 1 As shown, this embodiment is further optimized on the basis of embodiment 2, specifically:

[0030] The bottom surface of the hub 4 is evenly opened with a plurality of air inlets 7 in the circumferential direction, and each air inlet 7 is connected to an air inlet pipe 9 respectively, and all the air inlet pipes 9 are connected to the pitch control cabinet 5, and each air inlet pipe 9 is provided with There are fan 10.

[0031] A plurality of air inlet pipes 9 are evenly distributed inside the air guide 2, which can effectively improve the cooling efficiency. At the same time, the heat exchange through the air inlet pipes 9 can reduce the temperature in the air guide 2, thereby improving the temperature of all electrical appliances in the air guide 2. Component cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com