New preparation method for artificial stress corrosion crack accordant with true crack shape

A stress corrosion cracking and real stress technology, applied in the field of artificial stress corrosion cracking preparation, can solve the problems of difficult preparation of artificial stress corrosion cracking test specimens, unknown electrical conductivity in the crack area, uncontrollable crack size, etc., achieving easy realization and processing cost. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

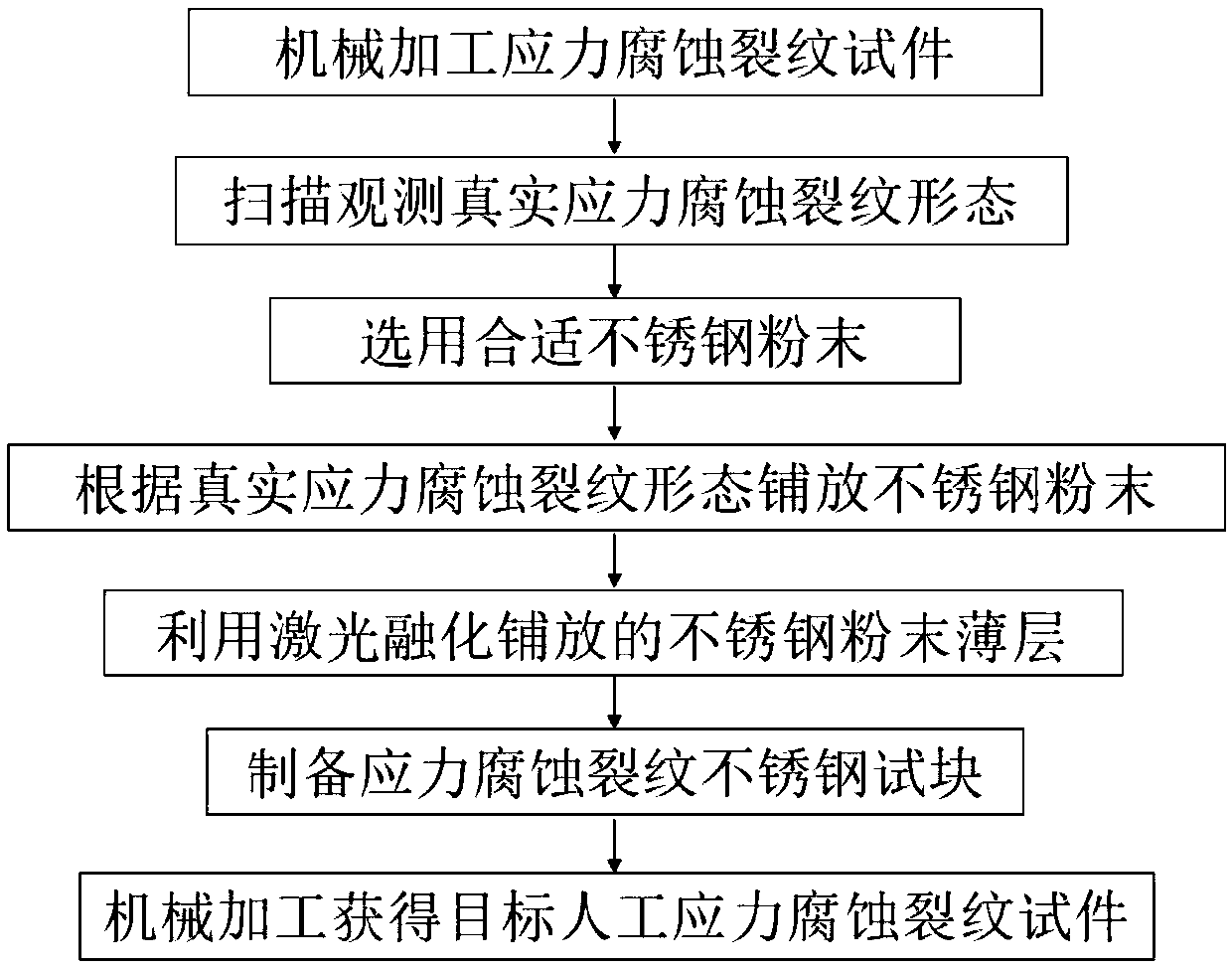

[0022] Such as figure 1 Shown is the flow chart of the present invention using 3D printing technology to prepare artificial stress corrosion cracks consistent with the shape of real cracks. Firstly, the real stress corrosion crack specimens are cut and processed, and the processed stress corrosion cracks are scanned and imaged in three dimensions by industrial CT. , to obtain the stress corrosion crack morphology map, and then use 3D printing technology to process and prepare artificial stress corrosion crack specimens consistent with the real crack morphology.

[0023] The following will combine figure 2 with image 3 The method of the present invention is further described in detail.

[0024] Step 1: Determination of real stress corrosion crack morphology, the specific steps are as follows:

[0025] 1) For example figure 2 The real stress corrosion crack test piece shown is machined, the part that does not contain cracks is removed, and the part that only contains stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com