General modular teaching practice device for chemical production lines

A general-purpose module and production line technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of lack of innovation ability, limited experimental ability, backward chemical production technology and equipment, etc., to achieve diversified use modes and facilitate experiments Observing and exercising the effect of manipulative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the public works module, the reaction module, the crystallization module, and the sieve plate rectification module are connected sequentially to form a modular teaching practice device for an aspirin production line, such as Figure 14 shown.

[0038] The device can modularize and scale the aspirin production line and install it in the laboratory, which is convenient for practical teaching work, and can be freely assembled to exercise students' hands-on ability and creative ability, and the risk is greatly reduced.

[0039] In the reaction module, add acetic anhydride solution to the acetic anhydride raw material tank fy1, add salicylic acid to the reactor fy3, turn on the reactor fy3 and the acid anhydride pump fy2, add the acetic anhydride raw material tank to the reactor fy3 through the acid anhydride pump fy2, and then Add concentrated sulfuric acid to the reactor fy3 through the constant pressure funnel on the reactor fy3, turn on the heating circulat...

Embodiment 2

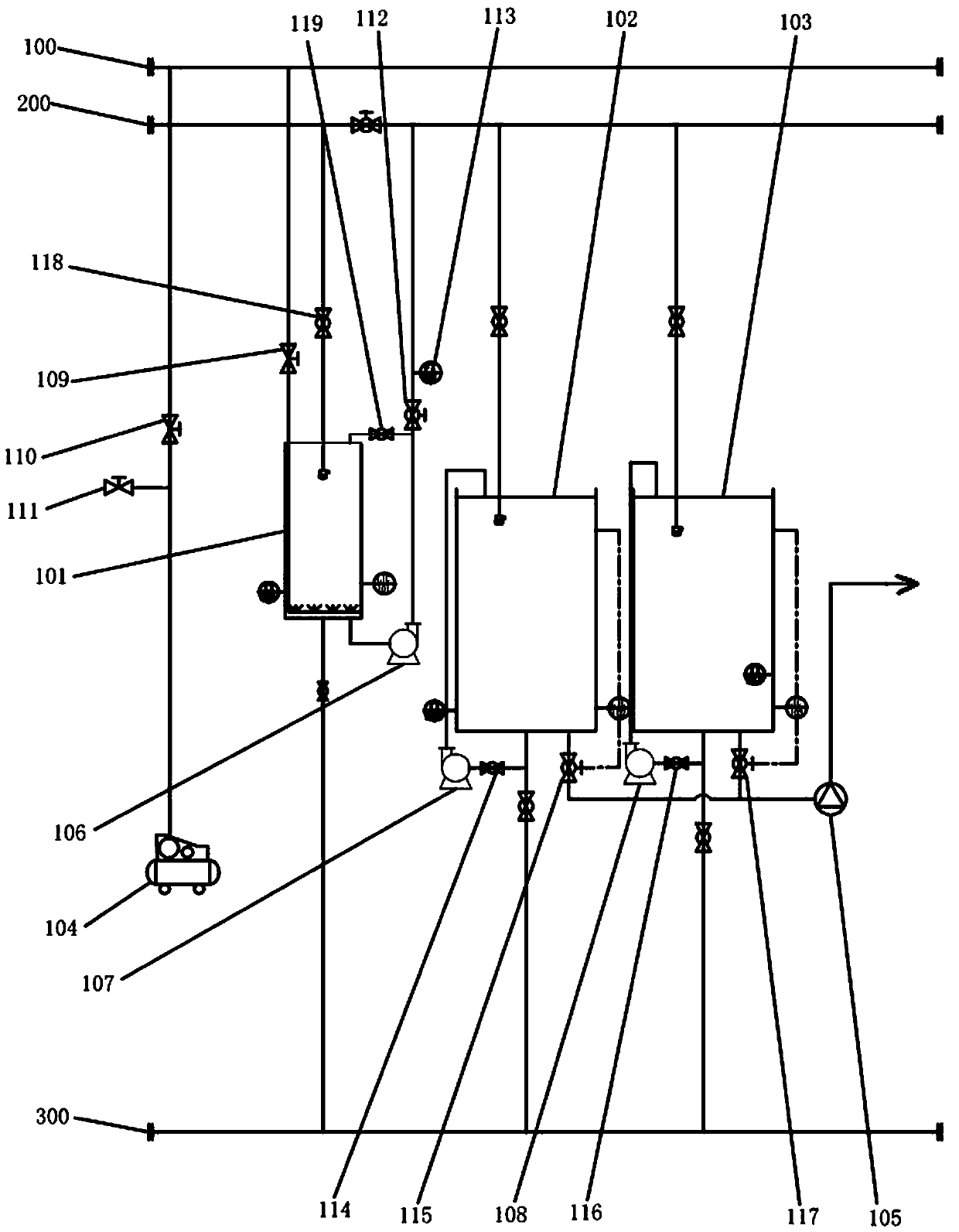

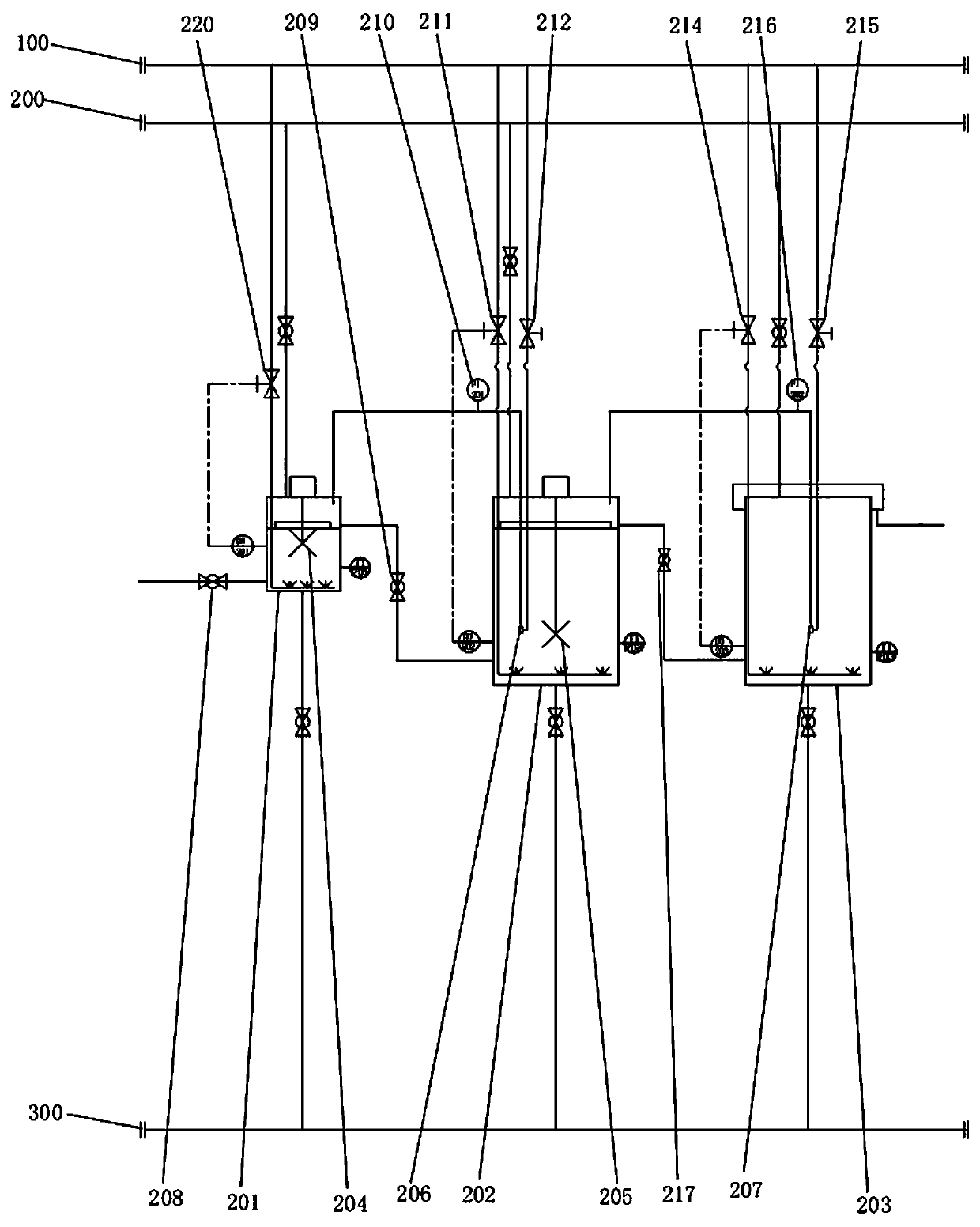

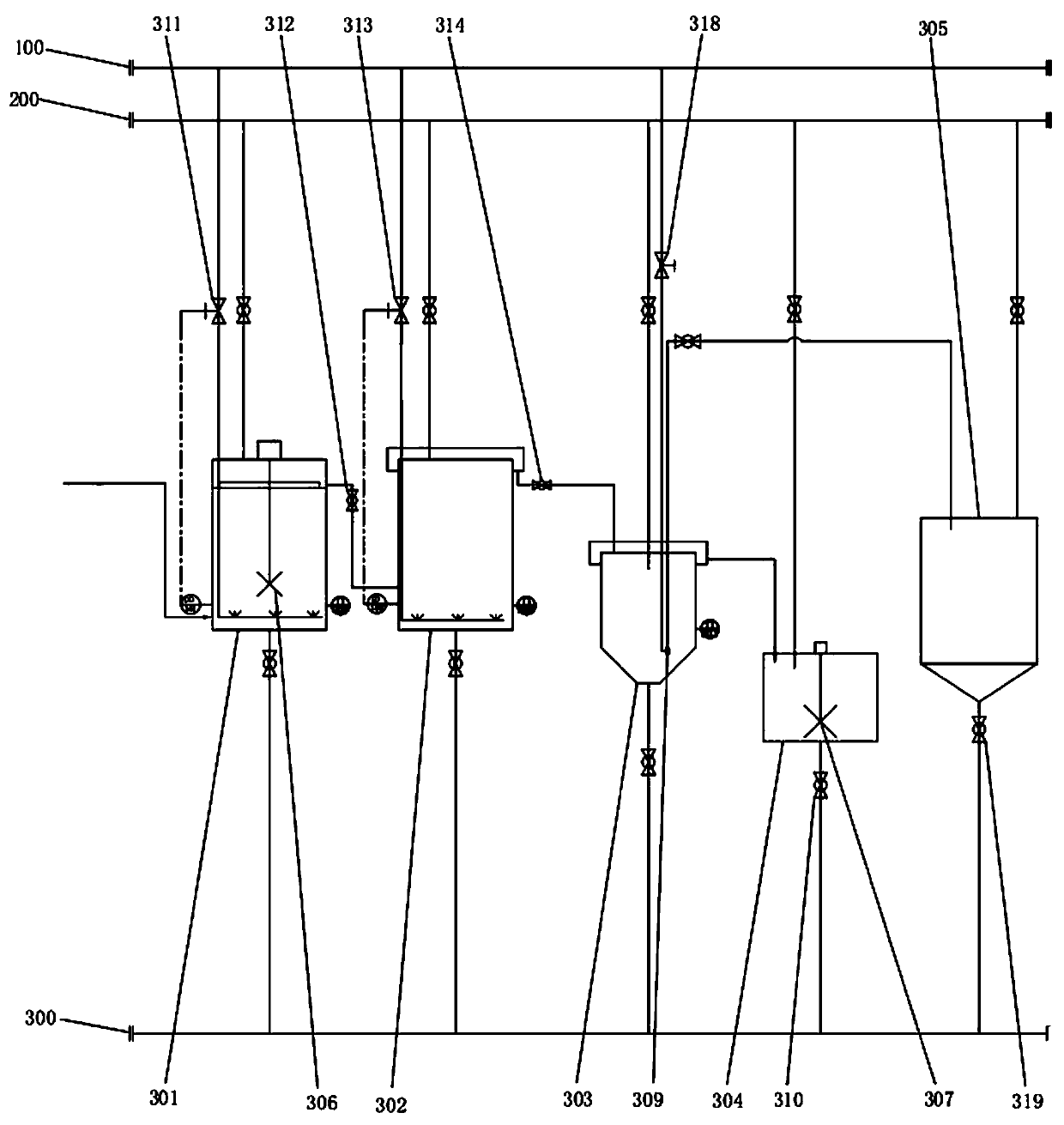

[0043] Embodiment 2: Connect the water distribution module, A2O module, and post-treatment module in sequence to form a teaching practice device for a sewage treatment production line, such as Figure 15 shown.

[0044] The practice method utilizing the teaching practice device of the sewage treatment production line comprises the following steps:

[0045] 1) Carry out practical operation of water distribution, including the following steps:

[0046] 1.1) According to practical requirements, manually set the upper limit and level difference of the circulating water tank 101 of the control system through the touch screen, and set the upper limit and temperature difference of the circulating water tank 101;

[0047] 1.2) Open the valve 118 to supply water to the circulating water tank 101. When the liquid level of the circulating water tank 101 rises to the actual required water level, open the valve 112, start the circulating water pump 106, and maintain the running state of t...

Embodiment 3

[0067] Embodiment 3: The public engineering module, the reaction module, the crystallization module, and the sieve plate rectification module are connected in sequence to form a modular teaching and practice device for a pharmaceutical intermediate production line.

[0068] For the specific operation process of the modular teaching practice device of the pharmaceutical intermediate production line, please refer to the Chinese invention patent with the application number: 201711173843.1 and the invention name: the teaching device for the benzamide production line. The teaching practice device has been publicly explained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com