Inorganic thermoelectric device having room temperature flexibility and preparation method thereof

A room temperature flexible, thermoelectric device technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric device node lead-out materials, etc., can solve the problem of low performance of pure organic thermoelectric materials, low power generation and refrigeration efficiency , can not meet the actual needs and other problems, and achieve the effect of simple preparation method, improved performance and suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

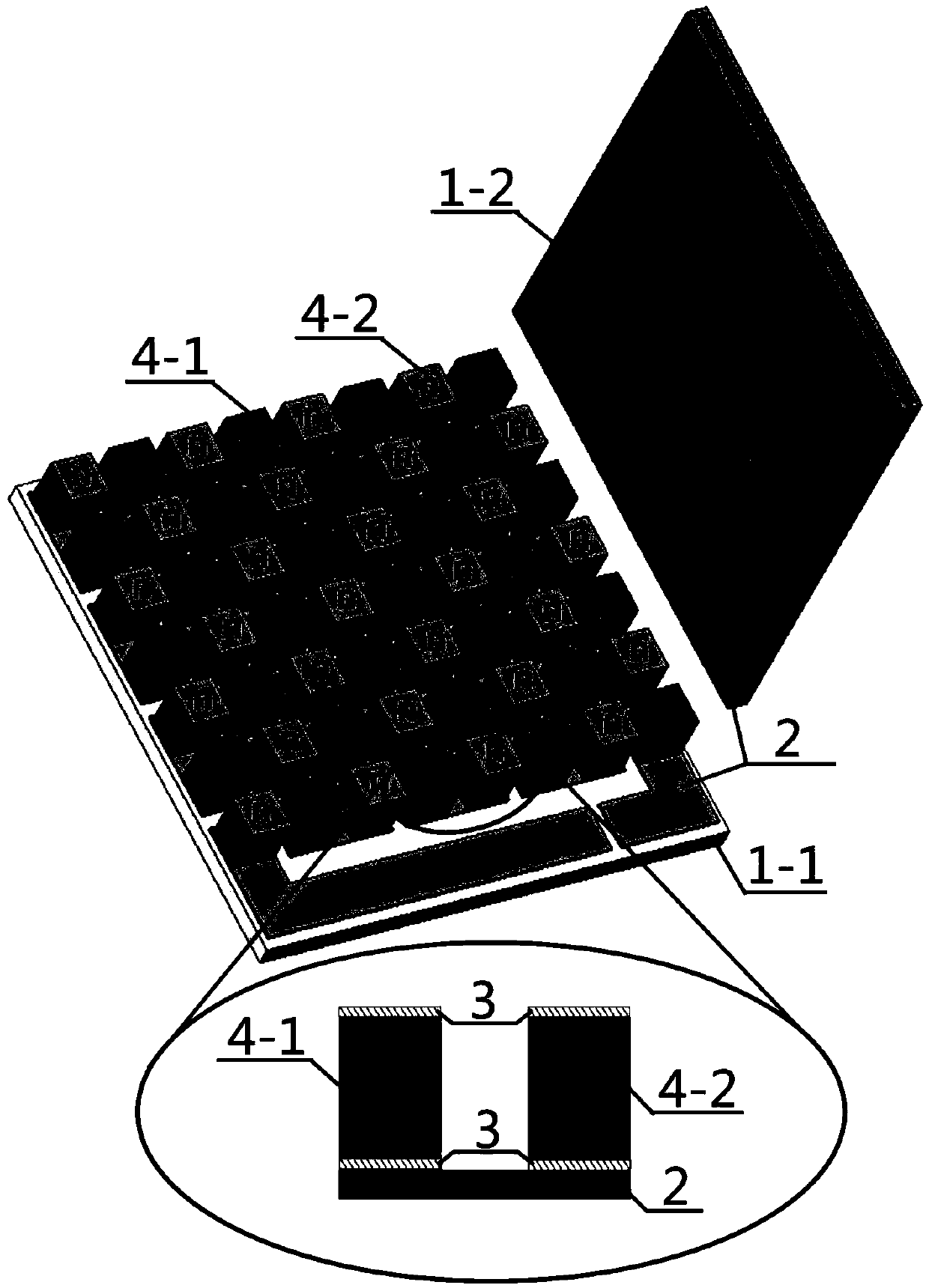

[0035] An inorganic thermoelectric device with room temperature flexibility, which includes from bottom to top: a lower substrate 1-1, an electrode 2, an anti-diffusion layer 3, and a p-type thermoelectric bulk material 4-1 with room temperature flexibility (p-Cu 2 Se) or an n-type thermoelectric bulk material with room temperature flexibility 4-2 (n-Ag 2 Se), the anti-diffusion layer 3 and the upper substrate 1-2; wherein, the opposite side of the lower substrate 1-1 and the upper substrate 1-2 are respectively provided with several electrodes 2 according to the circuit requirements, and the other side of each electrode 2 is connected with the chamber Soft and flexible thermoelectric bulk materials (p-type thermoelectric bulk material 4-1 and room temperature flexible n-type thermoelectric bulk material 4-2) are fixedly connected, and anti-diffusion is set between the contact surface of electrode 2 and thermoelectric bulk material Layer 3, the p-type thermoelectric material 4...

Embodiment 2

[0054] An inorganic thermoelectric device with room temperature flexibility, the structure of which is roughly the same as that of Example 1, except that the thermoelectric bulk materials used are p-type thermoelectric bulk materials with room temperature flexibility and n-type thermoelectric bulk materials with room temperature flexibility. type thermoelectric block material, the specific preparation method includes the following steps:

[0055] 1) Evaporate metal Cu thin film electrodes on 0.4mm thick glass fiber cloth, the specific parameters are as follows: the vacuum degree is 1×10 - 4 Pa, evaporation current 80A, substrate rotation speed 30r / min, the thickness of Cu thin film electrode on the substrate is about 120μm after 3min;

[0056] 2) On the ZPG-400A arc spraying machine, the size is Φ20×0.5mm 3 p-Ag 5 Te 3 and n-Ag 2 The upper and lower surfaces of Te dense block material are sprayed with a layer of anti-diffusion layer Mo, specifically: use Mo wire with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com