High-rate lead-acid storage battery built-in electrolyte formula and liquid injection process thereof

A lead-acid battery and electrolyte technology, applied in the field of electrochemical batteries, to achieve the effect of easy-to-obtain raw materials, simple addition process, and eliminate the phenomenon of over-dissolution of lead sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

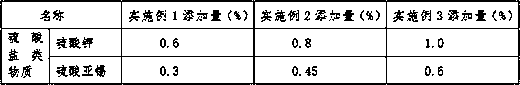

[0017] The high-rate lead-acid battery has a built-in electrolyte formula and its injection process. It is based on the conventional electrolyte and adds 0.9 to 1.6% of sulfate substances by mass percentage. The sulfate substances are composed of 0.6-1.0% potassium sulfate and 0.3-0.6% stannous sulfate. In order to verify the technical effect of the present invention, it is now described by three examples, and the specific addition amount is shown in the table below.

[0018] Table of Examples of Adding Sulfate Substances to Conventional Electrolyte

[0019]

[0020] According to the embodiment listed in the above table, the electrolyte is configured respectively, and its liquid injection process is carried out according to the following steps:

[0021] a. mix

[0022] The sulfate substances are added to the conventional electrolyte used, uniformly mixed under the condition of 200r / min for at least 10min.

[0023] b. Cool down

[0024] The above-mentioned mixed electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com