A series-fed planar printed array antenna

An array antenna, plane technology, applied in the direction of antenna, resonant antenna, antenna array, etc., can solve the problems of interruption, communication system connection impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

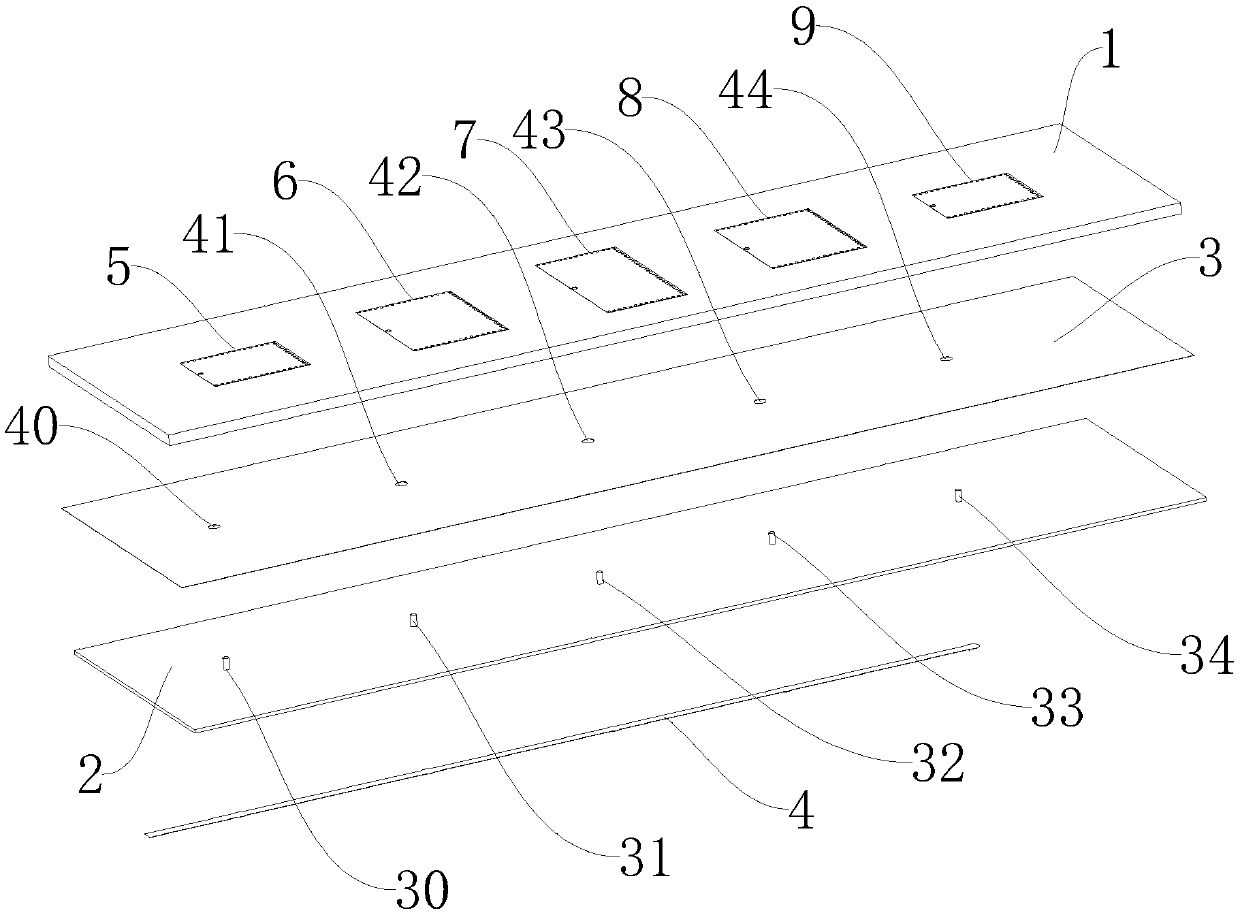

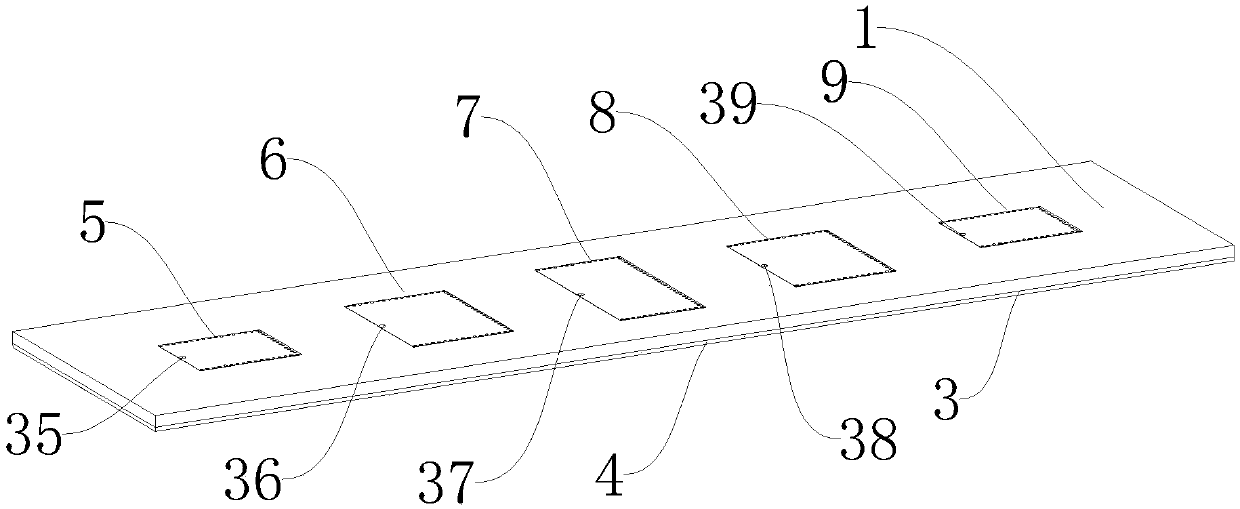

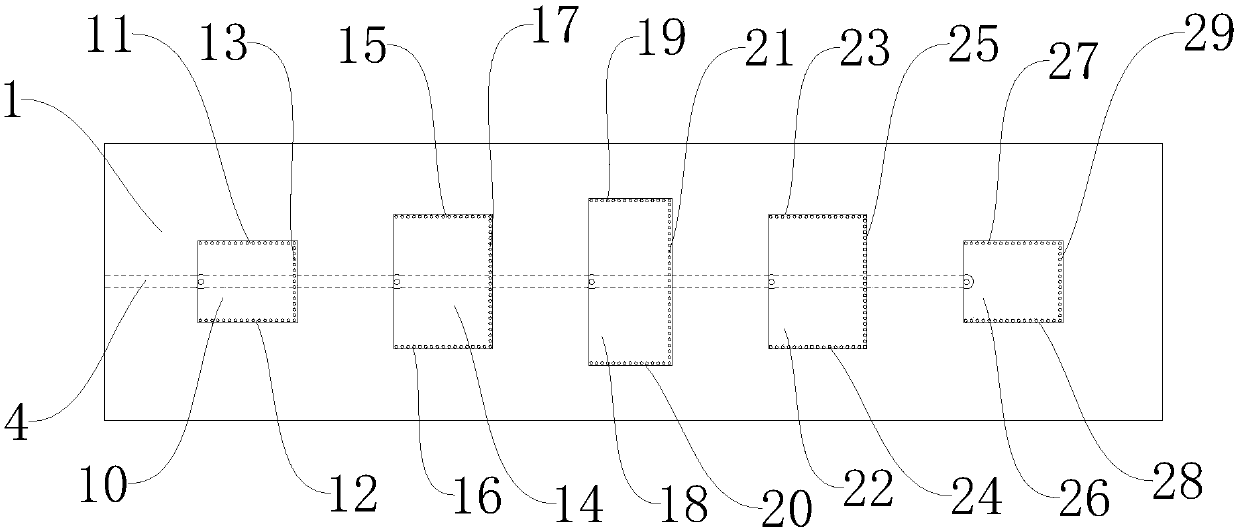

[0019] Embodiment 1: As shown in the figure, a series-fed planar printed array antenna includes an upper dielectric board 1, a lower dielectric board 2, a microstrip radiation group, a metal ground layer 3 and a microstrip feeder 4, the upper dielectric board 1, The lower dielectric board 2 and the metal grounding layer 3 are rectangular and the lengths of the long sides and wide sides of the three are respectively equal. The upper dielectric board 1, the metal grounding layer 3 and the lower dielectric board 2 are stacked together from top to bottom, and the metal grounding Layer 3 is attached to the upper surface of the lower dielectric board 2, the microstrip radiation group is arranged on the upper dielectric board 1, the microstrip feeder 4 is attached to the lower surface of the lower dielectric board 2, and the long side extension direction of the upper dielectric board 1 is taken as The left and right directions, the broadside extension direction as the front and rear d...

Embodiment 2

[0021] Embodiment two: this embodiment is basically the same as embodiment one, the difference is as follows:

[0022]In this embodiment, the length of the long side of the first rectangular metal block 10 is 13.89 mm, and the length of the wide side is 11.44 mm. The first group of metallized through holes 11 is formed by 16 metallized through holes arranged at intervals from left to right. The second group of metallized through holes 12 is formed by 16 metallized through holes arranged at intervals from left to right, and the third group of metallized through holes 13 is formed by 15 metallized through holes arranged at intervals from front to back. The center distance between every two adjacent metallized through holes in the metallized through holes 11 and the center distance between every two adjacent metallized through holes in the second group of metallized through holes 12 are both 0.82 mm. The center distance between every two adjacent metallized through holes in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long side length | aaaaa | aaaaa |

| Long side length | aaaaa | aaaaa |

| Long side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com