Assembling unit with PTC heating device

A technology for heating devices and assemblies, applied in ohmic resistance heating parts, ohmic resistance electrodes, ohmic resistance waterproof/airtightness, etc., can solve problems such as flashover and explosion, ensure bonding strength, improve safety and Reliability, Guaranteed Heat Dissipation Effect and Safety and Reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

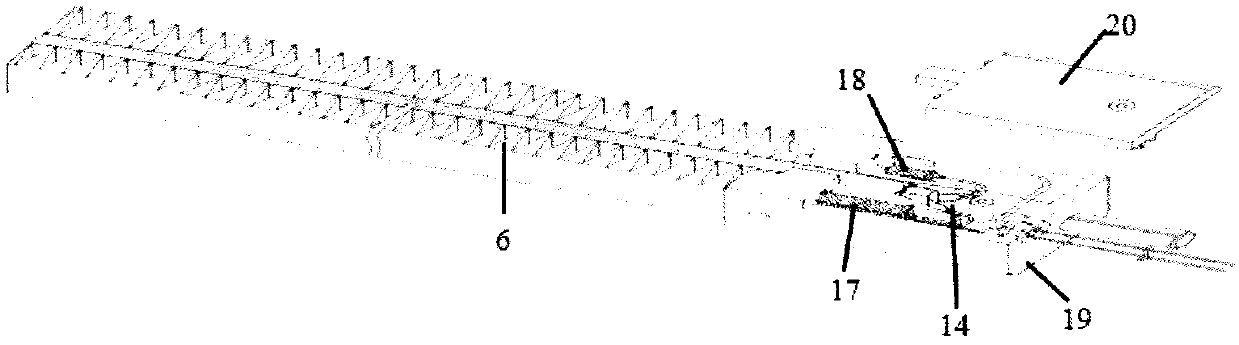

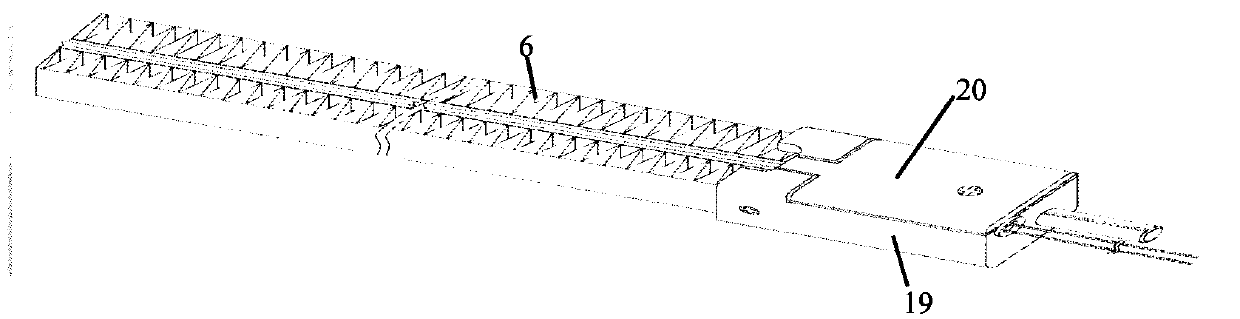

[0058] An assembly of PTC heating devices, including PTC heating devices, a first mounting bracket, a second mounting bracket 16, an incoming power harness connected with a temperature controller 17 and a temperature fuse 18, the first mounting bracket has a seat 19 and the cover 20, the surface electrified part of the electrode sheet lead-out ends of different polarities and the connection part connected to the power supply harness is covered with an insulating sleeve 37, and the insulating sleeve 37 and the electrode sheet lead-out ends are connected to the power supply harness The surface of the charged body of the connection part is coated with temperature-resistant, insulating sealant 14.

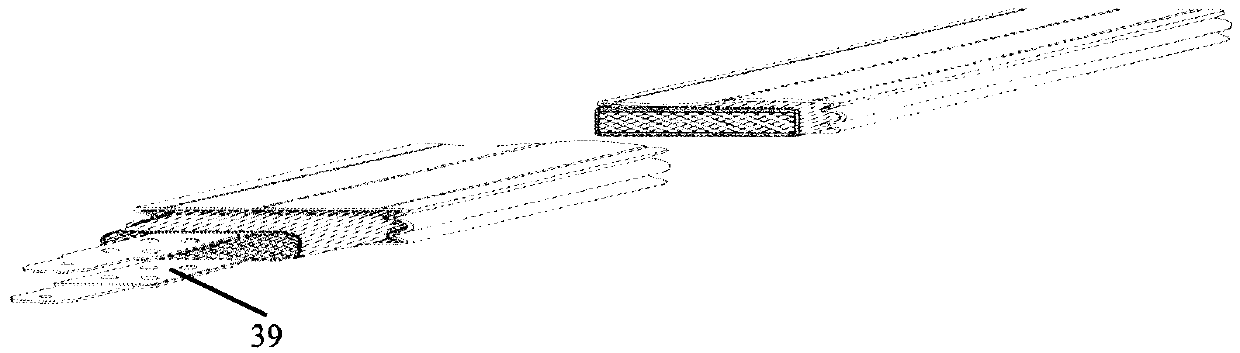

[0059] The connection mode of the connecting part is that the insertion spring 38 riveted on the wire harness and the insertion piece 39 connected to the lead-out end of the electrode piece 2 are inserted into each other.

[0060] The insulating sheath 37 is an insulating rubber sheath...

Embodiment 2

[0070] An assembly of PTC heating elements, comprising a PTC heating element, a first mounting bracket, a second mounting bracket 16, a power wire harness connected with a temperature controller 17 and a temperature fuse 18, and the second mounting bracket 16 is nested in The tail end of the heating device, the tail of the non-electrode lead-out end of the heating device is coated with a heat-resistant sealant 14 to completely seal the gap at the tail end of the heating device.

[0071] The heat-conducting aluminum tube 1 at the tail end of the heating device exceeds the tail end of the heating device by 0.5-10mm, and the bottom surface of the cavity of the second mounting bracket has a cavity for accommodating the protruding part of the tail of the heat-conducting aluminum tube 1 . The insulating sealant 14 is poured.

[0072] There are chamfers or grooves around the side walls of the cavity where the second mounting bracket 16 is combined with the heat-generating device of t...

Embodiment 3

[0081] An electrical appliance, including a PTC heating device and an assembly.

[0082] The electrical appliance is at least one selected from air conditioners, heaters, hot air curtains, bathroom heaters, dehumidifiers, air purifiers, clothes dryers, new energy vehicle heaters or defoggers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com