PCB production line

A PCB board and production line technology, applied in the field of digital direct writing exposure machine, can solve the problems of unstable quality, PCB board damage, hand fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

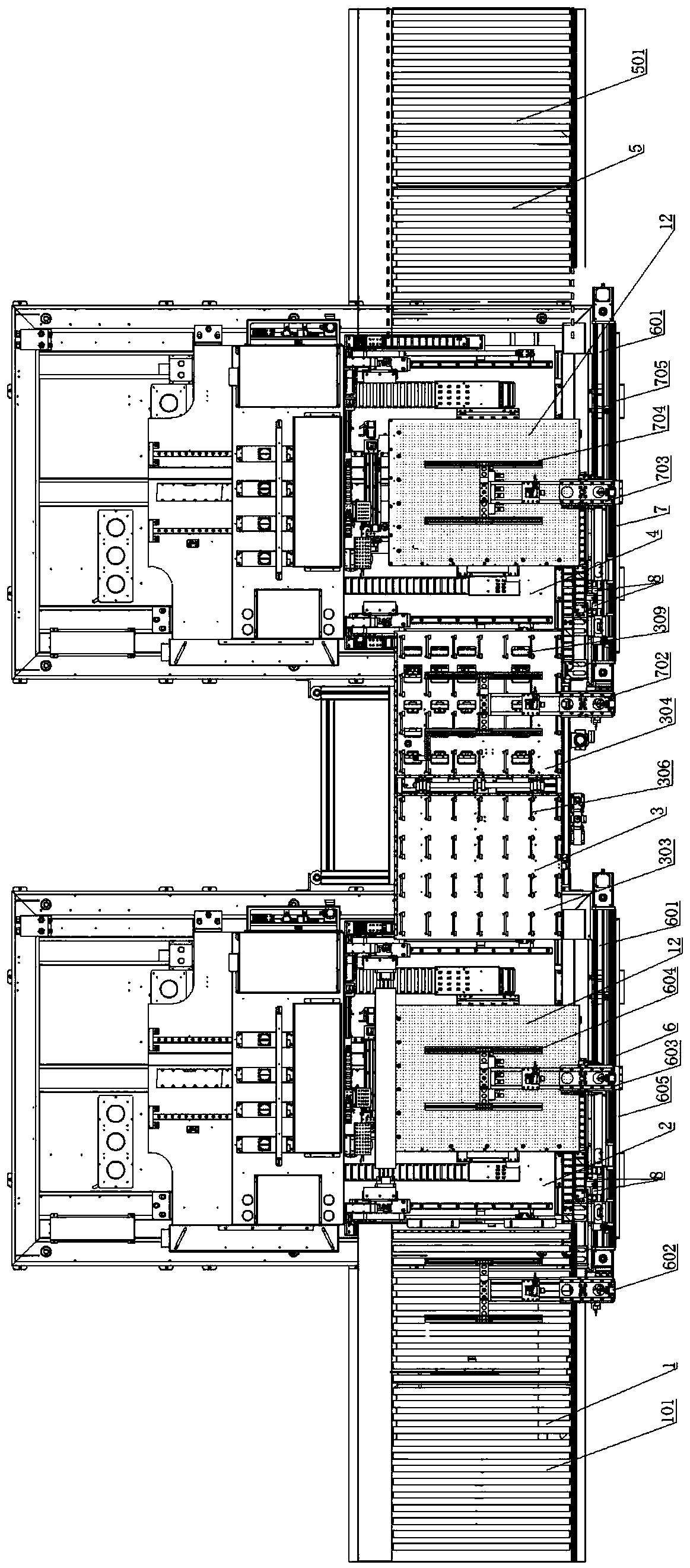

[0028] See figure 1 , a production line for PCB boards, including sequentially set:

[0029] The feeding conveyor 1 is used for feeding the PCB board, and the front side of the PCB board on the feeding conveyor 1 is facing upward and the back is facing downward;

[0030] The first photolithography machine 2 is used to expose and print patterns on the front side of the PCB board;

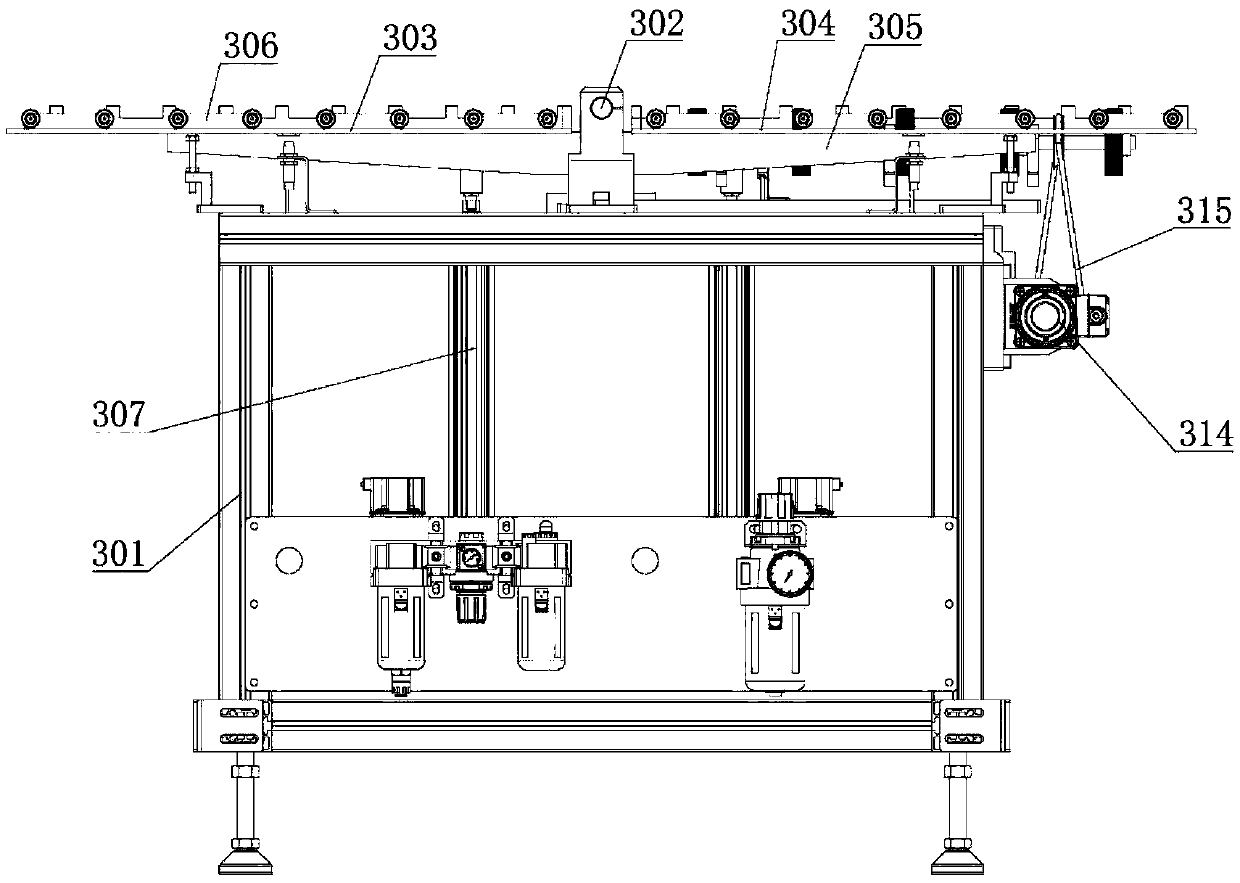

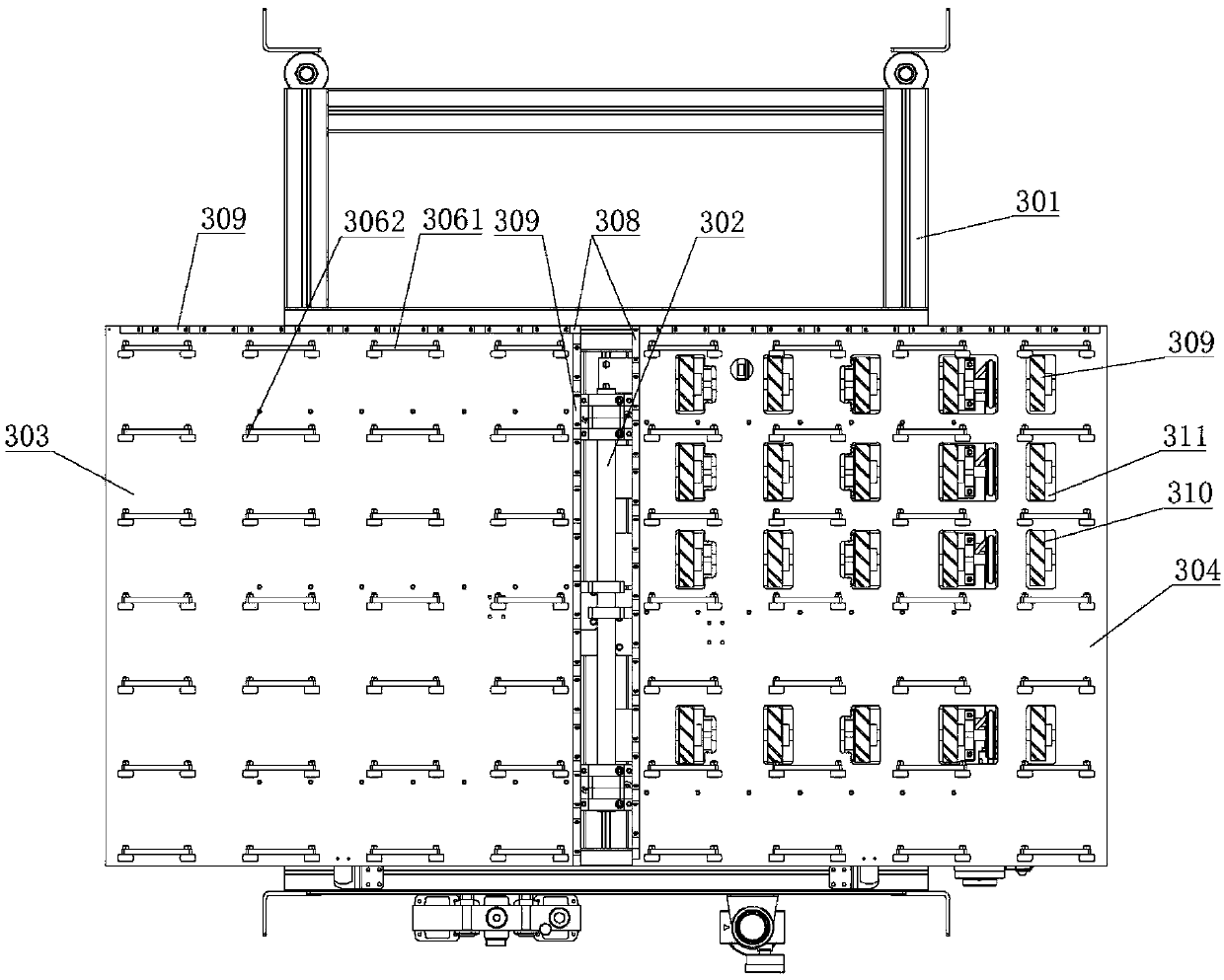

[0031] The board turning machine 3 is used to turn over the PCB board so that the back side of the PCB board faces up;

[0032] The second photolithography machine 4 is used to expose and print graphics on the back of the PCB board;

[0033] Discharging conveyor 5, used for the discharging of PCB board;

[0034] It also includes a first transfer machine 6 arranged on one side of the first photoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com