Railway Vehicle Smart Bolt Oiler

A technology of intelligent bolts and oiler, which is applied in roads, constructions, laying tracks, etc., can solve problems such as low efficiency and difficulty in oiling rail bolts, and achieve the effects of improving flexibility, protecting operation safety, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

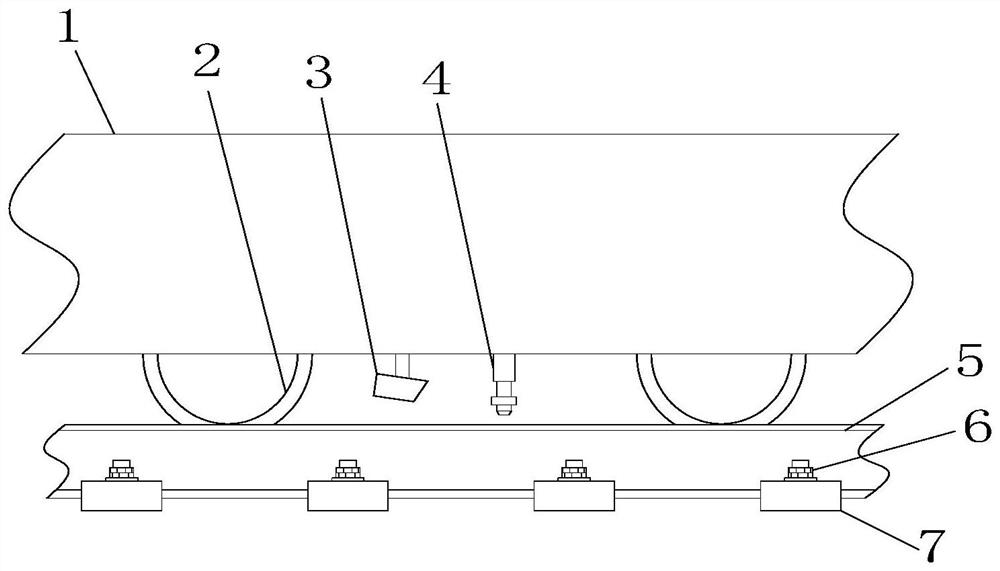

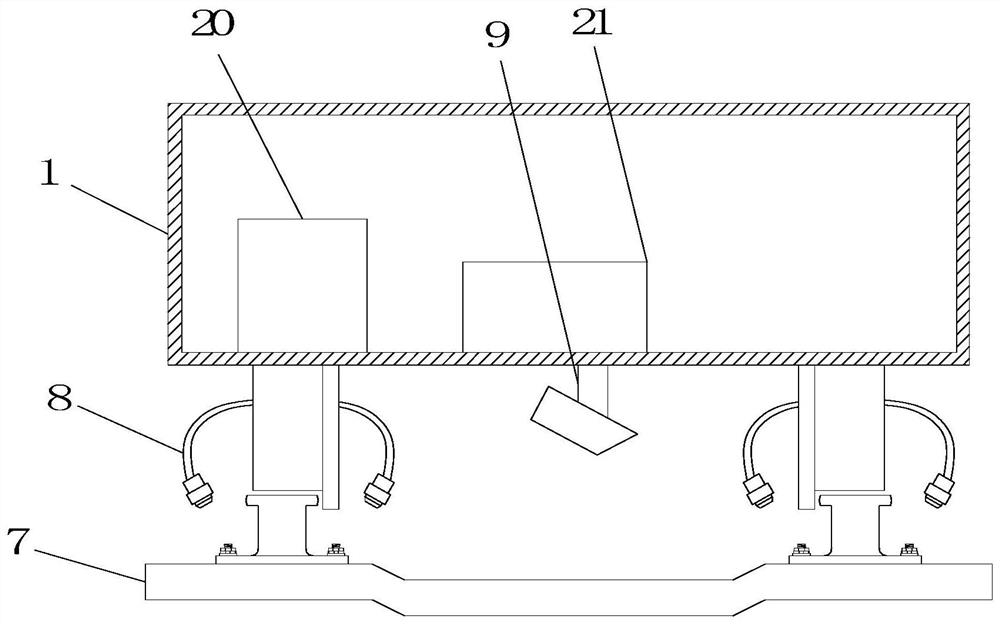

[0032] Embodiment one, with reference to Figure 1-3, railway vehicle intelligent bolt oiler, including compartment 1, compartment 1 is an existing railway freight or passenger carriage, compartment 1, wheels 2 and rail 5 form an existing conventional railway track structure, wherein rail 5 is fixed on the rail by bolt 6 On the crossties 7, an oiling mechanism 4 and a monitoring camera 3 are arranged between the wheels 2 at the front and rear positions of the bottom of the compartment 1. The monitoring camera 3 is located behind the oiling mechanism 4 and is fixed to the bottom of the compartment 1 by a support rod 9. When avoiding lubricating oil splashing on the monitoring camera 3 to affect the line of sight, wherein the oiling mechanism 4 includes a high-voltage electromagnetic fuel injector 14, an electromagnetic inductor 15 is installed on the high-voltage electromagnetic injector 14, and the high-voltage electromagnetic injector 14 passes through The gooseneck 8 bends o...

Embodiment 2

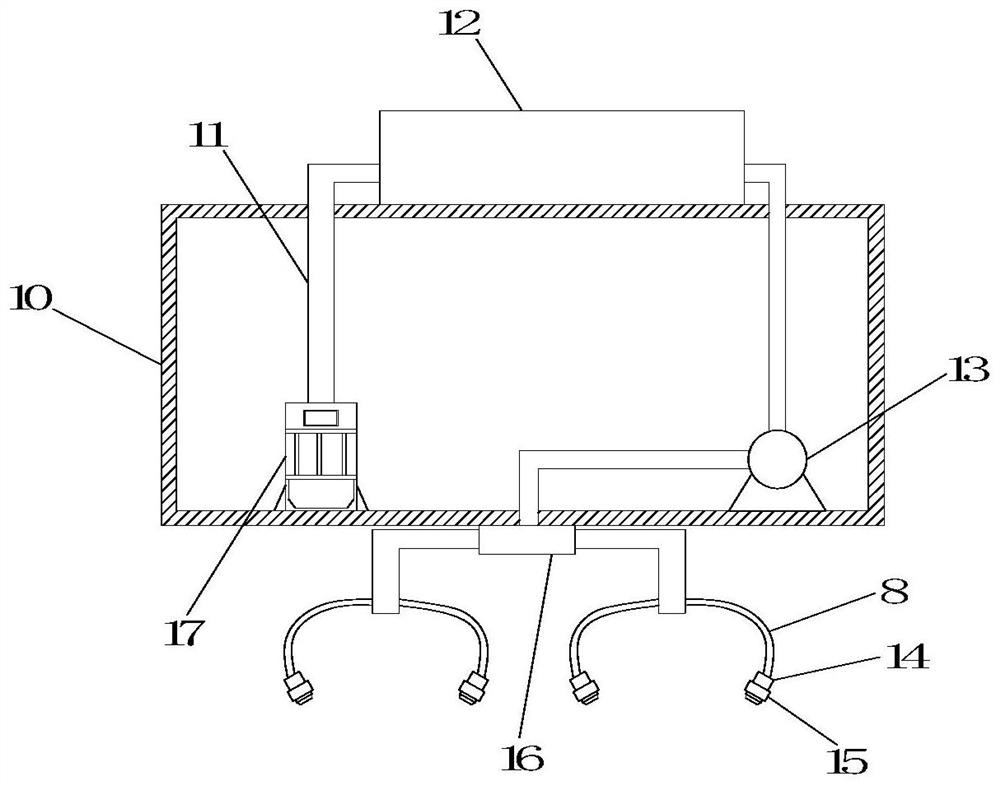

[0034] Embodiment two, refer to Figure 1-5 , railway vehicle intelligent bolt oiler, including compartment 1, compartment 1 is an existing railway freight or passenger carriage, compartment 1, wheels 2 and rail 5 form an existing conventional railway track structure, wherein rail 5 is fixed on the rail by bolt 6 On the crossties 7, an oiling mechanism 4 and a monitoring camera 3 are arranged between the wheels 2 at the front and rear positions of the bottom of the compartment 1. The monitoring camera 3 is located behind the oiling mechanism 4 and is fixed to the bottom of the compartment 1 by a support rod 9. Avoid splashing lubricating oil on the surveillance camera 3

[0035] The line of sight is heard, wherein the oiling mechanism 4 includes a high-voltage electromagnetic fuel injector 14, and an electromagnetic inductor 15 is installed on the high-voltage electromagnetic injector 14. Bend, and finally align with the bolt 6, the compartment 1 is provided with a fuel stora...

Embodiment 3

[0039] Embodiment three, refer to Figure 1-3 , railway vehicle intelligent bolt oiler, including compartment 1, compartment 1 is an existing railway freight or passenger carriage, compartment 1, wheels 2 and rail 5 form an existing conventional railway track structure, wherein rail 5 is fixed on the rail by bolt 6 On the crossties 7, an oiling mechanism 4 and a monitoring camera 3 are arranged between the wheels 2 at the front and rear positions of the bottom of the compartment 1. The monitoring camera 3 is located behind the oiling mechanism 4 and is fixed to the bottom of the compartment 1 by a support rod 9. When avoiding lubricating oil splashing on the monitoring camera 3 to affect the line of sight, wherein the oiling mechanism 4 includes a high-voltage electromagnetic fuel injector 14, an electromagnetic inductor 15 is installed on the high-voltage electromagnetic injector 14, and the high-voltage electromagnetic injector 14 passes through The gooseneck 8 bends outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com