Bamboo breaking device with automatic knife changing function

An automatic tool changing and bamboo breaking technology, which is applied in mechanical equipment, sugarcane machining, etc., can solve the problems of low automation, cumbersome control process, and low work efficiency, and achieve the effect of high work efficiency, optimization of cumbersome process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

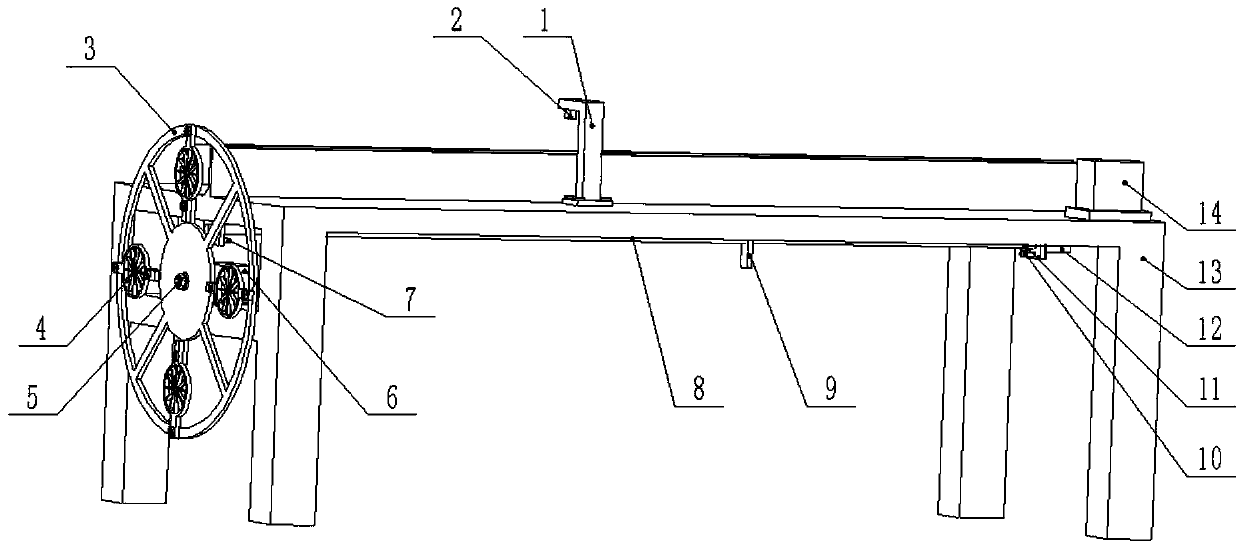

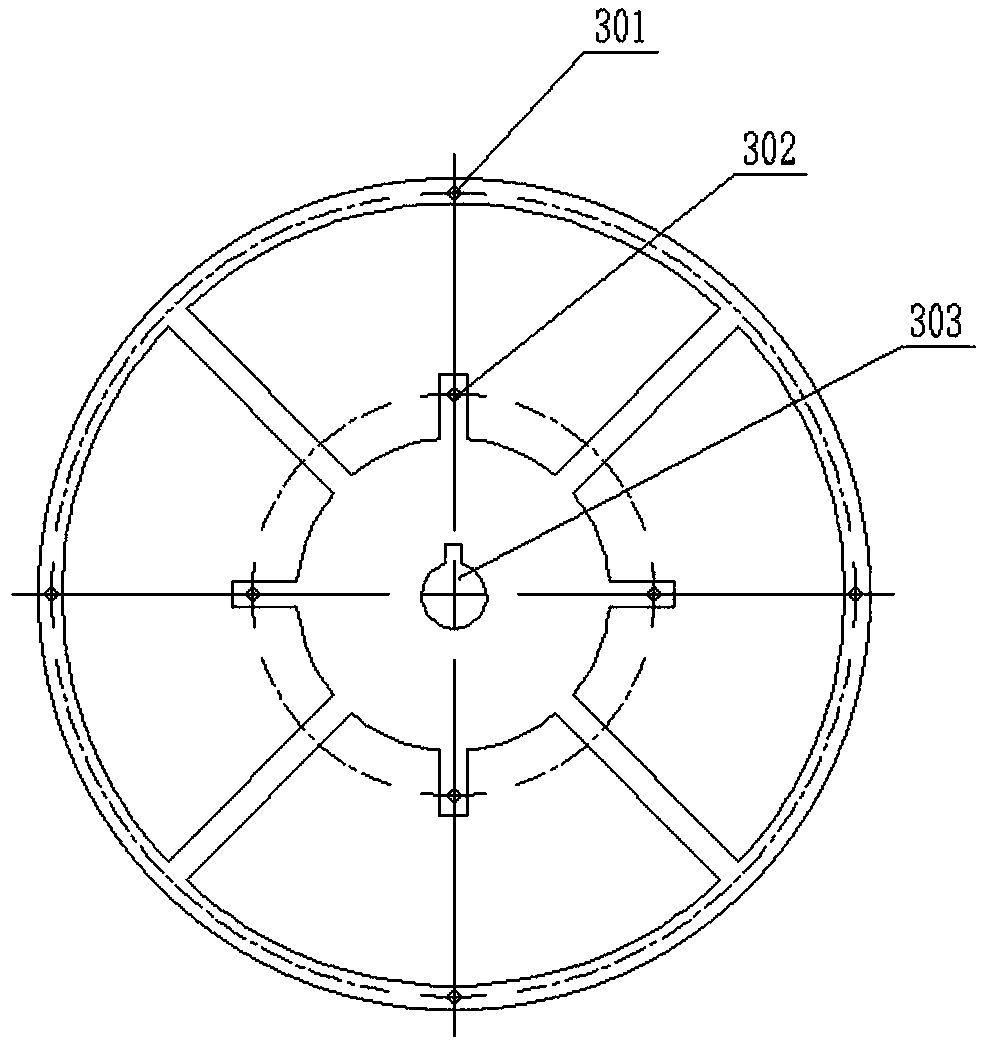

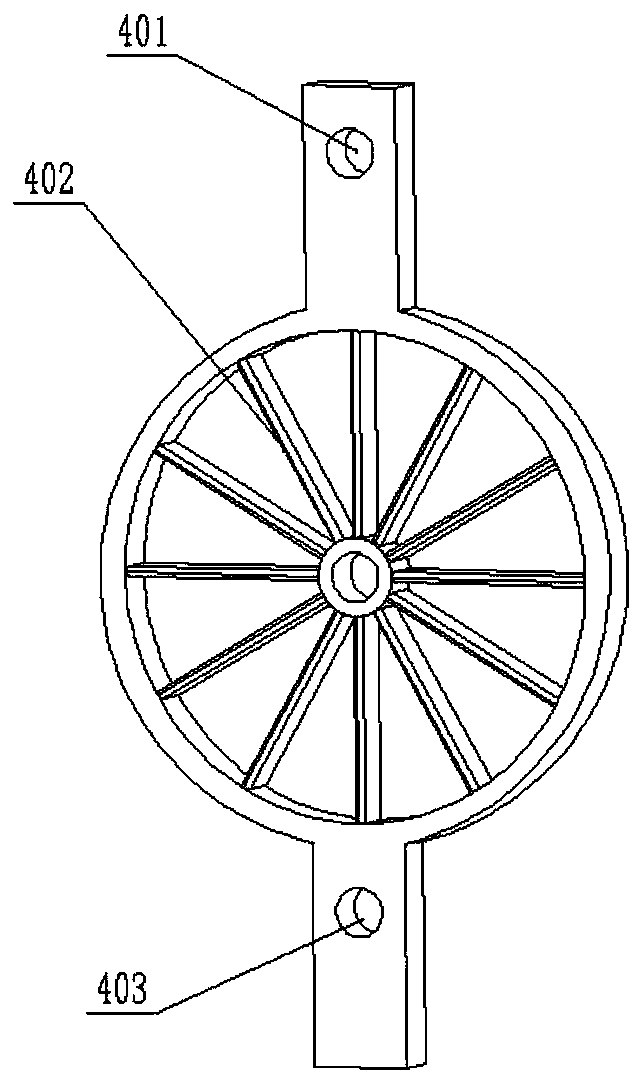

[0013] A bamboo breaking device with automatic tool change, which is composed of a sensor bracket 1, a diameter measuring laser ranging sensor 2, a knife holder 3, a bamboo breaking knife 4, a self-locking nut 5, a stepping motor system with a built-in encoder 6, and an end limit switch 7. Lead screw 8, push plate 9, head end limit switch 10, coupling 11, servo motor 12, base 13, control box 14, the first fixed threaded hole 301 of the bamboo cutter, the second fixed threaded hole 302 of the bamboo cutter , knife rest mounting hole 303, the first mounting hole 401 of the broken bamboo knife, the broken bamboo knife blade 402, the second mounting hole 403 of the broken bamboo knife, the stepping motor 601 of the built-in encoder, the first coupling 602, the knife rest connecting shaft 603, Stepping motor with built-in encoder fixing light hole 604, push plate installation threaded hole 901, bamboo running groove 1301, push plate walking opening 1302, screw mounting hole 1303, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com