Quality detection device, method and system and integrated probe component

A quality detection method and detection device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low detection efficiency, low reliability, scratches on the workpiece surface, etc., and achieve high detection efficiency, high reliability, The effect of less abnormal fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

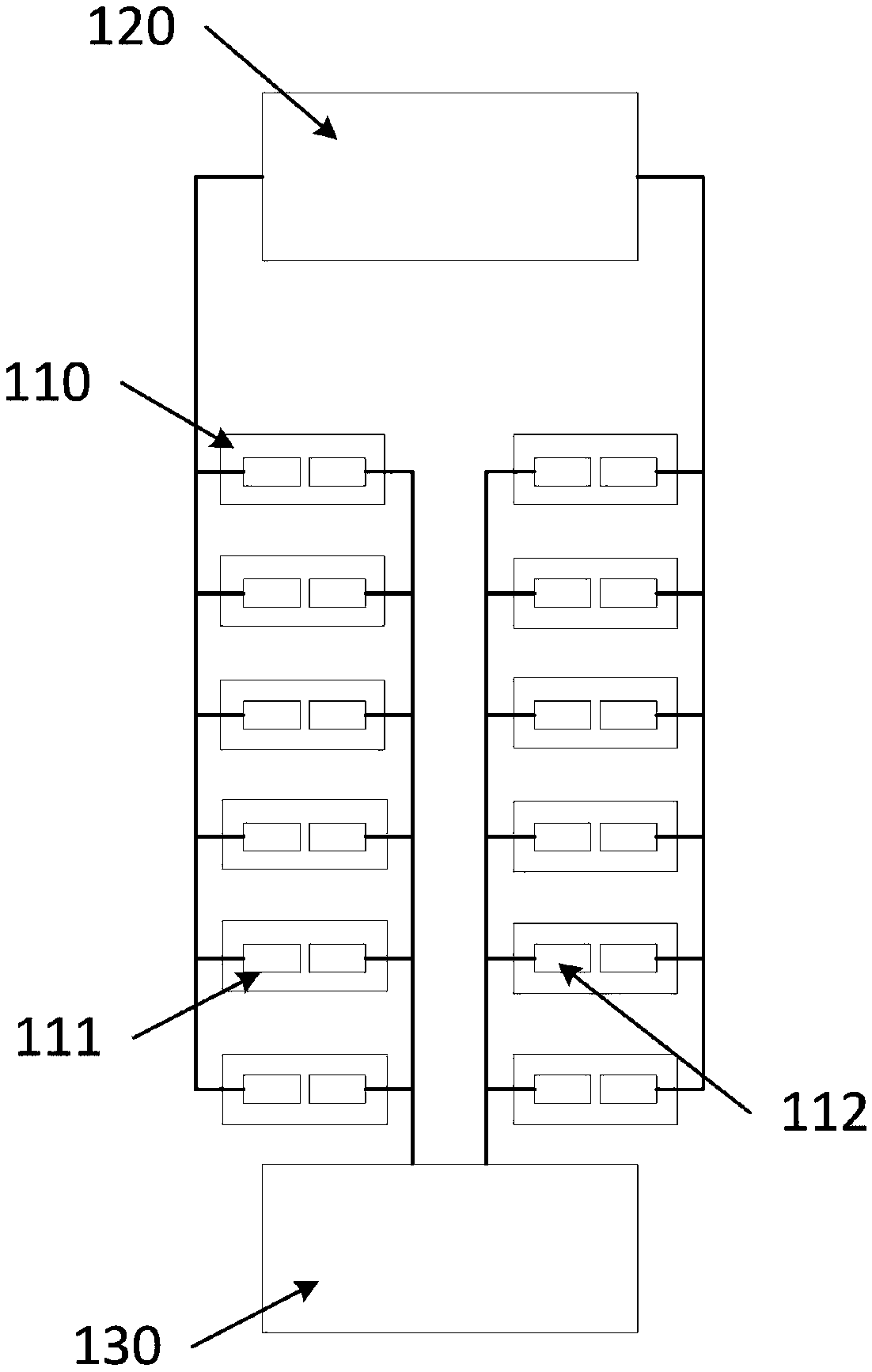

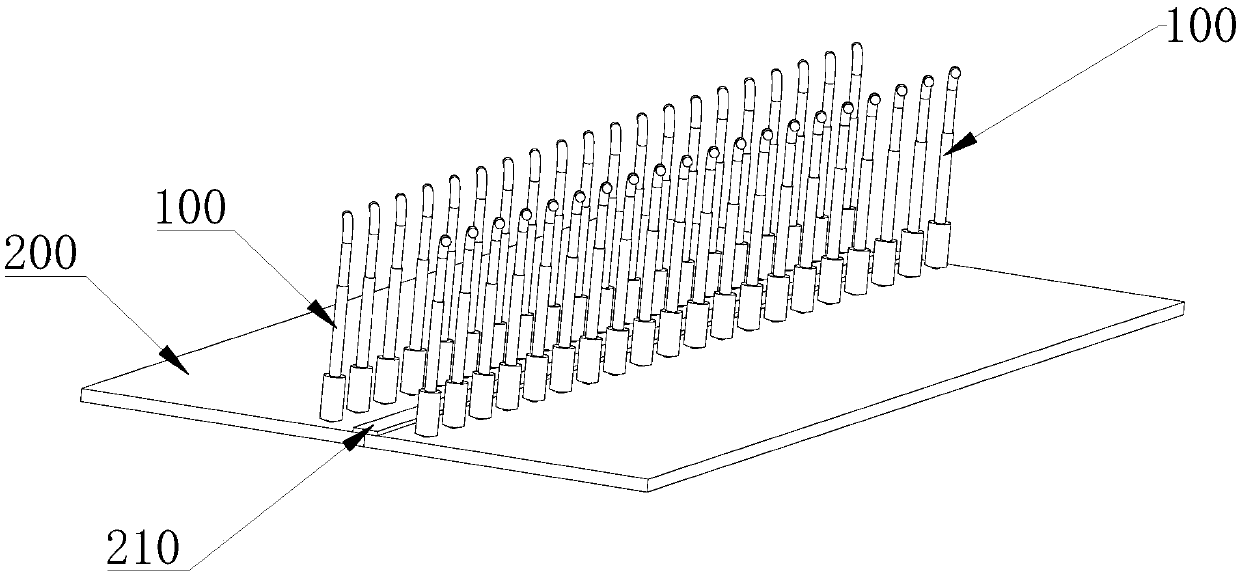

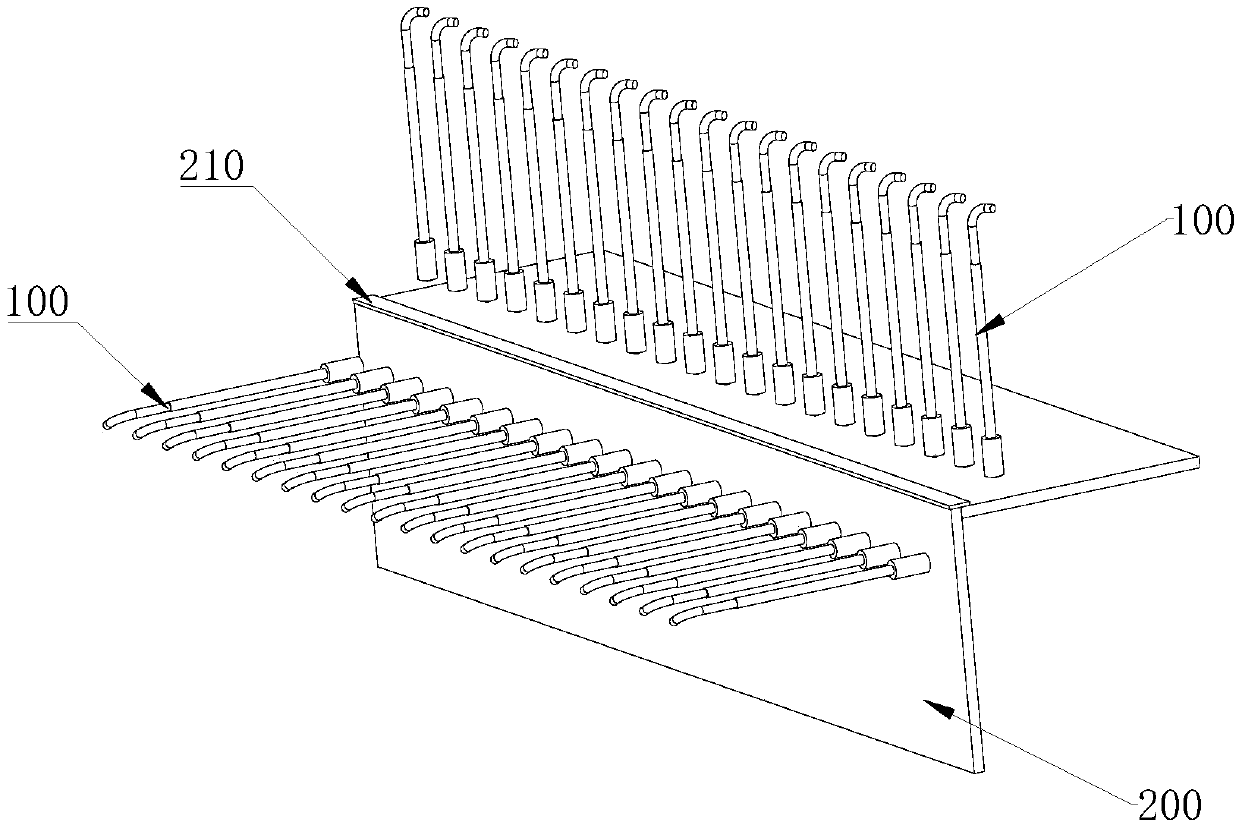

[0034] like Figure 1 to Figure 3 As shown, the present invention provides a preferred embodiment of a quality detection device.

[0035] A quality detection device, the quality detection device includes an integrated probe set, a drive module 130 and an acquisition module 120, the integrated probe set includes a plurality of paired configurations and consists of a drive end 112 and an acquisition end 111 One-piece probe assembly 110, and the driving end 112 of the one-piece probe assembly 110 is matched with the driving end 112 of another one-piece probe assembly 110 arranged in pairs, and the one-piece probe assembly 110 The collection terminal 111 is matched with the collection terminal 111 of another body type probe assembly 110 arranged in pairs, and the driving module 130 releases the current to form a current loop with the conflict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com