A greening method for high and steep quartzite slopes in dry and rainless areas

A dry, less rainy, quartzite technology, applied in the direction of soil preparation methods, botanical equipment and methods, climate change adaptation, etc., can solve problems such as difficult to ensure the survival rate of planting green plants, low water conservation of rocks, etc., to achieve large wear and fixed time Short, hard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

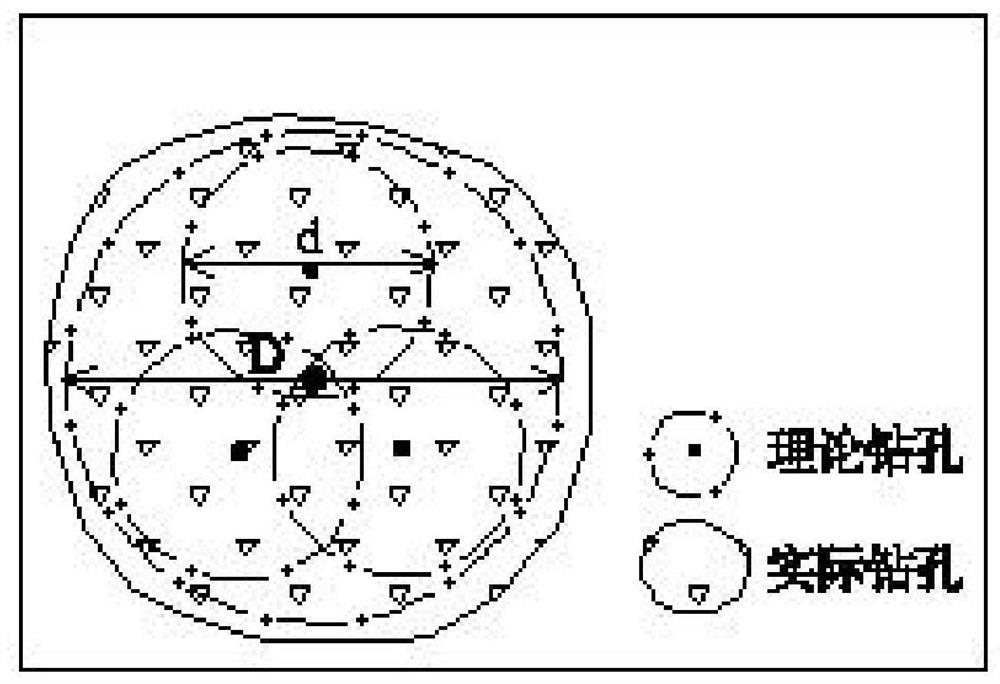

[0020] A greening method for high and steep slopes of quartzite in dry and rainless areas, such as figure 1 shown. Described method is specifically as follows:

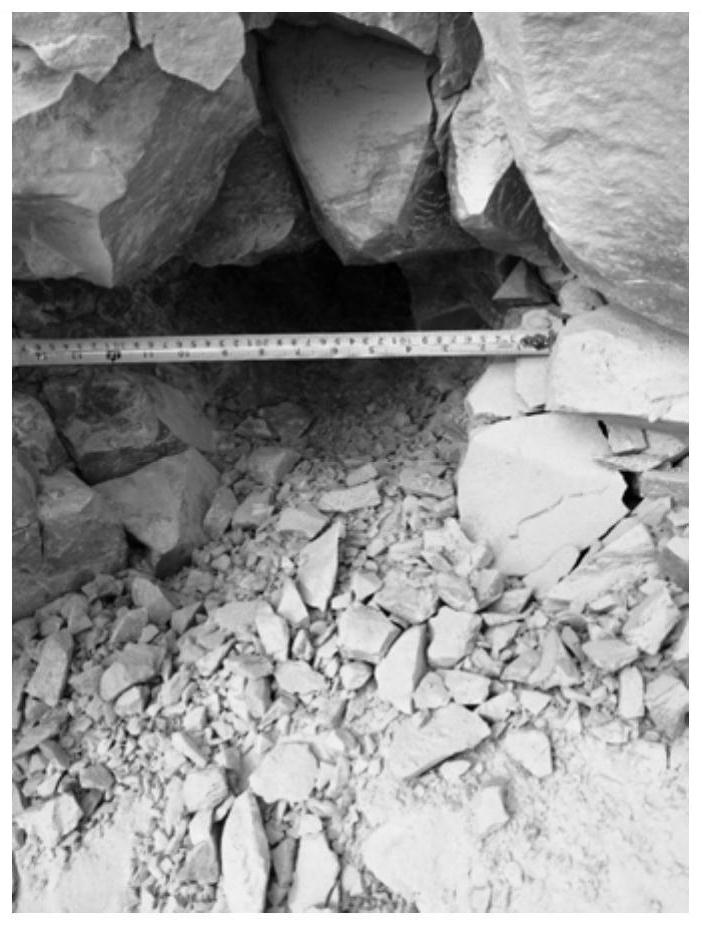

[0021] 1) Drill horizontally on the slope with a borehole of 100 mm in diameter, such as figure 2 shown.

[0022] 2) Drill a second hole with a diameter of 100mm at the bottom left of the first hole 80mm from the edge of the first hole, that is, the center point of the second hole is 80mm from the edge of the first hole;

[0023] 3) On the right side of the second hole, drill the third hole at a distance of 80mm from the edge of the first hole and the second hole, and the diameter of the drill bit used is 100mm, that is, the center point of the third hole is 80mm away from the edge of the second hole. The distance between the edges of the first hole and the second hole is equal, and both are 80mm, and the centers of the three holes are connected to form an equilateral triangle, such as image 3 shown;

[0024] 4...

Embodiment 2

[0026] A method for afforesting high and steep quartzite slopes in dry and rainless areas, the method is specifically as follows:

[0027] 1) Drill horizontally with a 100mm borehole on the slope.

[0028] 2) Drill a second hole with a diameter of 100mm at the bottom left of the first hole 90mm from the edge of the first hole, that is, the center point of the second hole is 90mm from the edge of the first hole;

[0029] 3) On the right side of the second hole, drill the third hole at a distance of 90mm from the edge of the first hole and the second hole, and the diameter of the drill bit used is 100mm, that is, the center point of the third hole is 90mm away from the edge of the second hole. The distance between the edges of one hole and the second hole is equal, and both are 90mm, and the centers of the three holes are connected to form an equilateral triangle;

[0030] 4) The disturbance generated during the drilling process naturally expands the extension of each hole, mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com