Magnesium aluminum pentafluoride/attapulgite/porous carbon composite material and preparation method and application thereof

A technology of attapulgite and composite materials, which is applied in chemical instruments and methods, water/sludge/sewage treatment, alkali metal compounds, etc., and can solve problems that affect the adsorption performance of attapulgite, fail to achieve environmental protection, and weaken physical and chemical properties. , to achieve significant superiority, low price, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

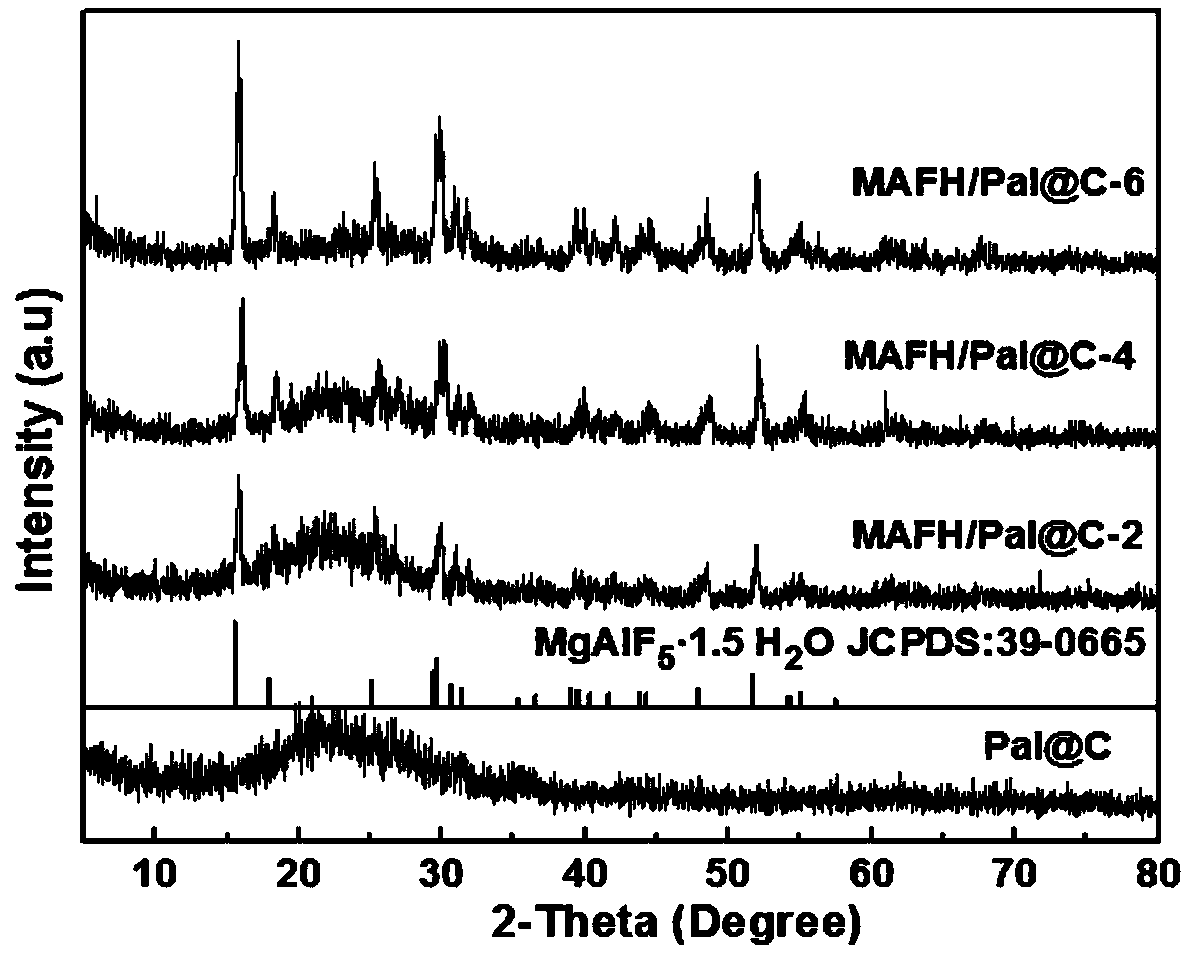

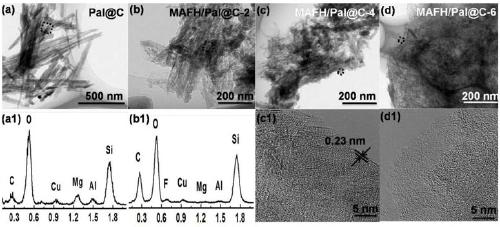

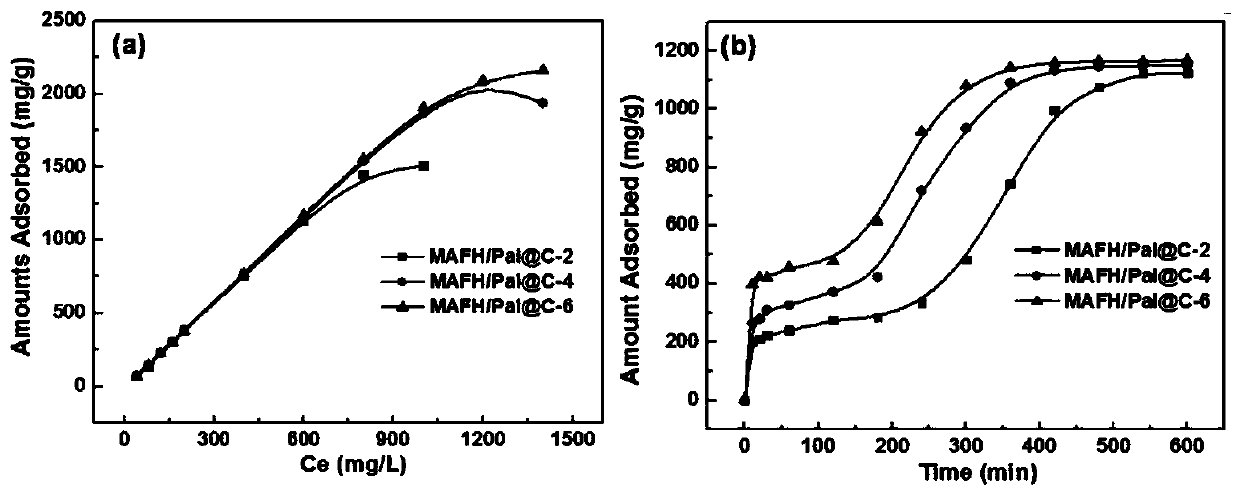

Method used

Image

Examples

Embodiment 1

[0032] Step a: Modification of raw ore attapulgite: 1) Purification: first, sieve the raw ore attapulgite with a 150-mesh sieve to obtain attapulgite raw ore powder (Pal powder) for later use; weigh 5.0g of the sieved Pal powder+ 2.0g NH 4 Cl+1.0g NaCl in a 500mL beaker, then add 232.0mL deionized water+11.0mL concentrated HNO 3 +7.0mL concentrated H 2 SO 4 Stir vigorously for 4 hours; after stirring, immerse for 0.5 hours, pour out the upper liquid, and only filter the lower part, wash with absolute ethanol and deionized water until neutral, and finally dry at 80°C; 2) Surface activation and production Hole: acidify the above dried sample with 250.0mL of HCl solution with a concentration of 5mol / L for 2 hours, filter with suction after acidification, wash with absolute ethanol and deionized water until neutral, and finally place in an oven Dry at 80°C;

[0033] Step b: Preparation of glucose-modified attapulgite precursor: Weigh 3.0g modified attapulgite and 2.0g glucose ...

Embodiment 2

[0041] Step a: Same as Example 1.

[0042] Step b: Preparation of glucose-modified attapulgite precursor: namely, the surface of modified attapulgite adsorbs carbon source, weigh 3.0g of modified attapulgite and 0.75g of glucose into a 500mL beaker, add 40.0mL of deionized water and continue Stir for 24 hours, and then place in a water bath at 80° C. until the water evaporates to prepare a precursor.

[0043] Step c: Put the precursor in a tube furnace with a helium gas flow rate of 40mL / min, a heating rate of 10°C / min, and roast at 700°C for 4h to obtain Pal@C.

[0044] Step d: Add Pal@C obtained in step c to 4 ml of 40% HF, add 6 ml of water, heat and stir at 80°C for 8 hours; wherein, the mass ratio of Pal@C, hydrofluoric acid and water is about 1:4:6; then filter with suction and wash with deionized water and absolute ethanol several times until neutral, then dry it in an oven at 90°C for 10 hours to obtain magnesium aluminum pentafluoride / attapulgite / porous carbon compo...

Embodiment 3

[0048] Step a: Same as Example 1.

[0049] Step b: Preparation of glucose-modified attapulgite precursor: namely, the surface of modified attapulgite adsorbs carbon source, weigh 3.0g modified attapulgite and 3.0g glucose into a 500mL beaker, add 40.0mL deionized water and continue Stir for 24 hours, and then place in a water bath at 80° C. until the water evaporates to prepare a precursor.

[0050] Step c: Put the precursor in a tube furnace with a nitrogen gas flow rate of 40mL / min, a heating rate of 8°C / min, and roast at 900°C for 2.5h to obtain Pal@C.

[0051] Step d: Add Pal@C obtained in step c to 6 ml of 40% HF, add 4 ml of water, and heat and stir at 80°C for 8 hours; wherein, the mass ratio of Pal@C, hydrofluoric acid and water is about 1 : 6: 4; then suction-filtered and washed several times with deionized water and absolute ethanol until neutral, and then dried in an oven at 70°C for 6 hours to obtain pentafluoromagnesium aluminum / attapulgite / porous carbon composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap