Laserstamping forming method and device

A laser stamping and laser technology, applied in the field of laser processing, can solve the problems of affecting the service life of the laser, reducing the speed of sheet metal forming, increasing the difficulty of sheet metal molding, etc., to avoid melting and oxidation, improve forming accuracy, and good The effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical details proposed by the present invention will be described in detail below with reference to the accompanying drawings.

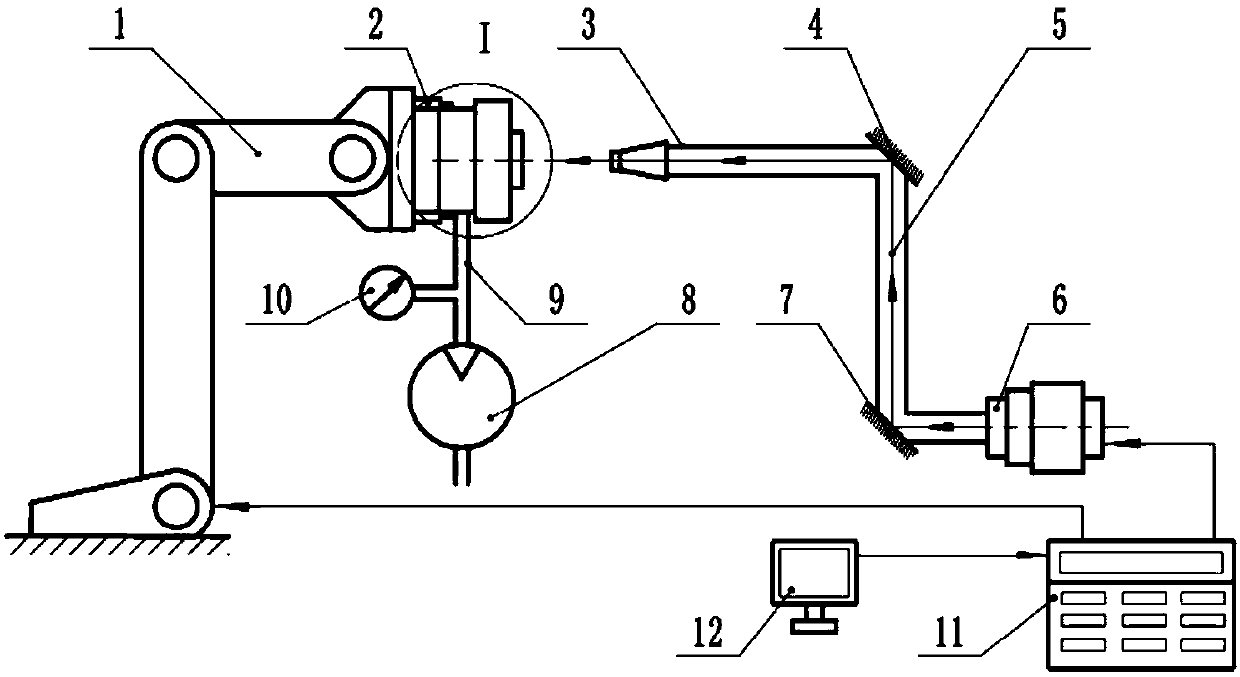

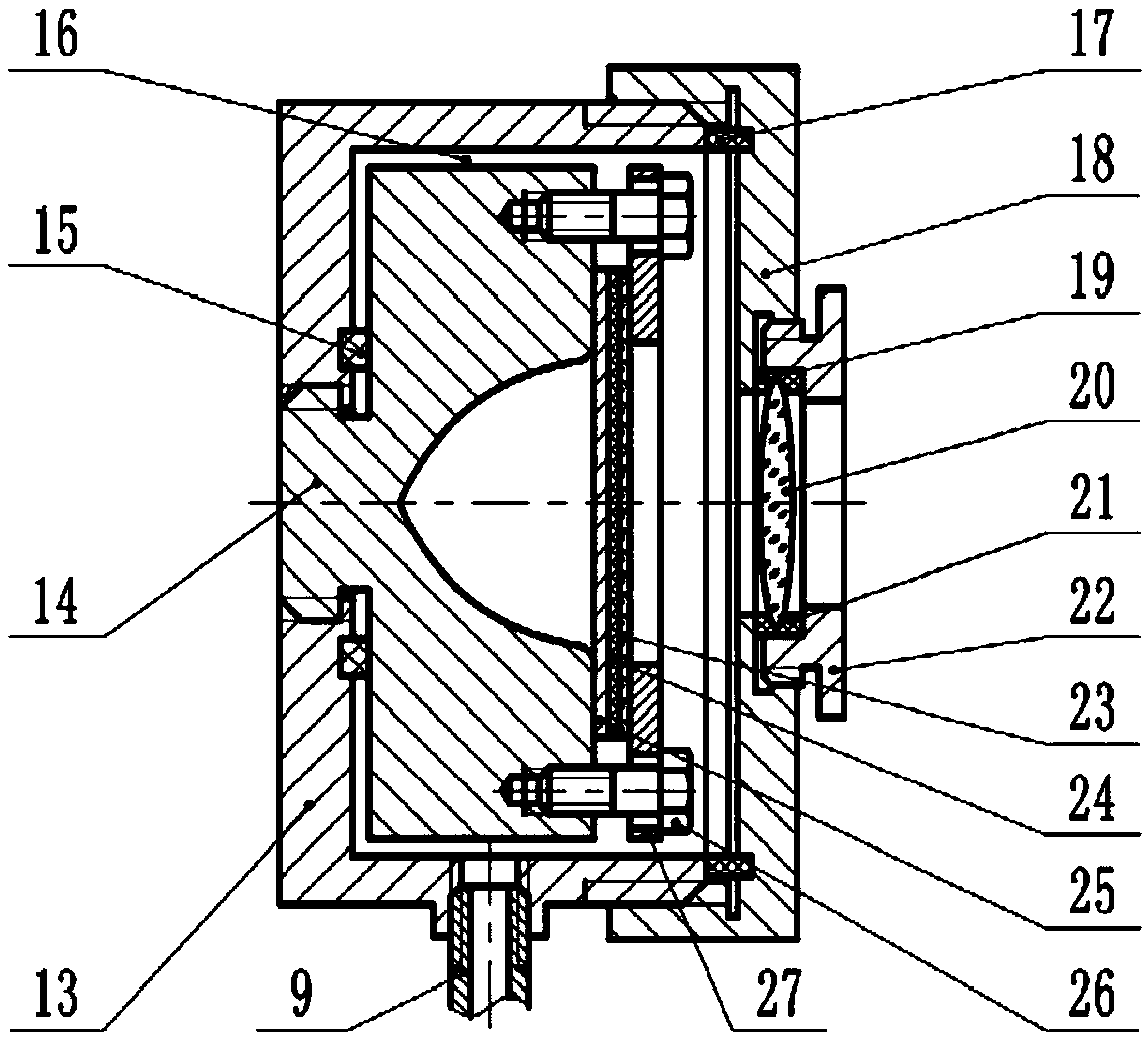

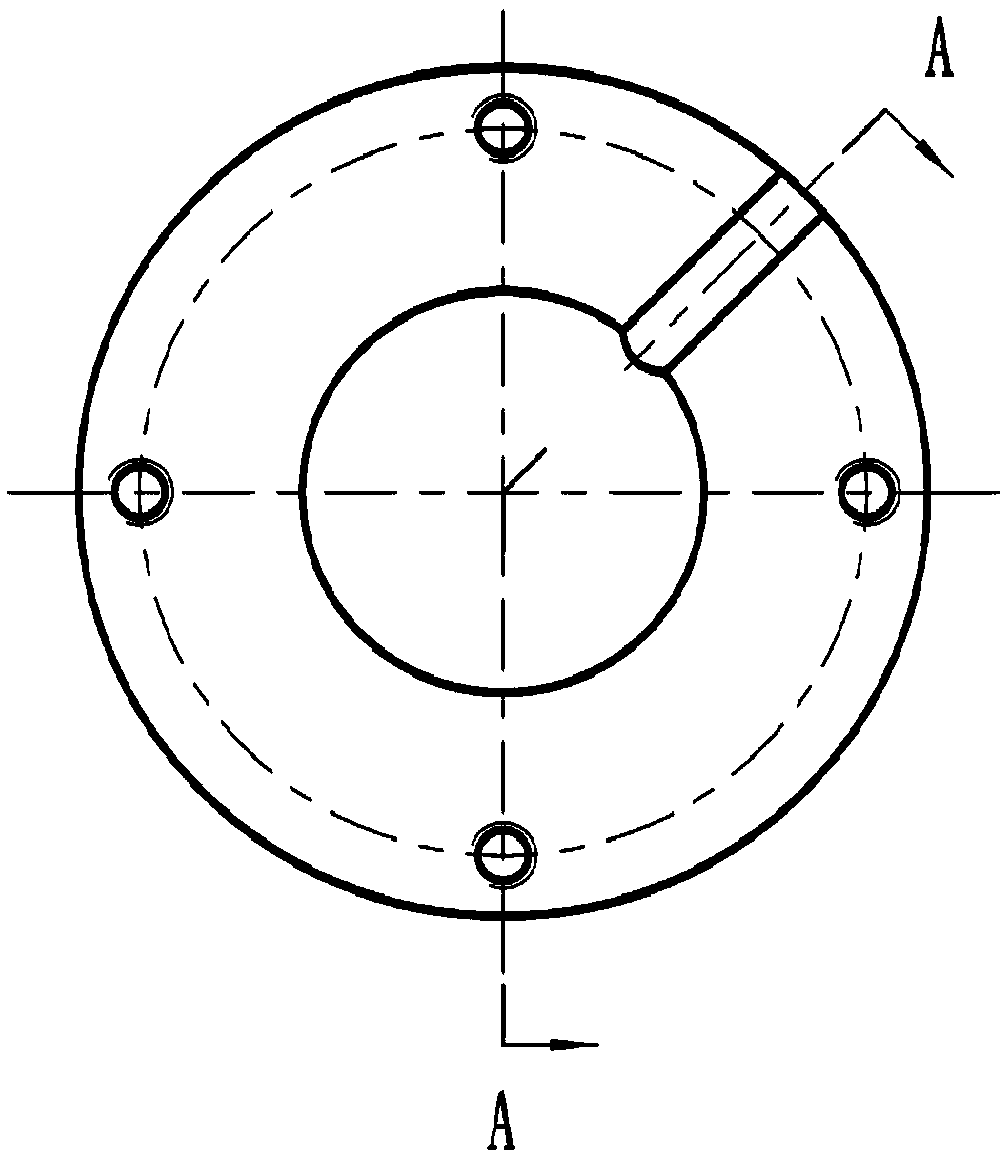

[0022] The device of the present invention includes a laser 6, a light guide system, a workpiece mold system, and a control system; the light guide system includes a light guide tube 3, a pulsed laser beam 5, a first total reflection mirror 7, a second total reflection mirror 4, a converging lens 20, Optical glass 23; one end of the light pipe 3 is connected to the laser 6, and the first total reflection mirror 7 and the second total reflection mirror 4 are connected in turn, the first total reflection mirror 7 and the second total reflection mirror 4 Mainly to change the propagation direction of the pulsed laser beam 5, the outlet of the light pipe 3 is facing the converging lens 20, the axis of the light pipe 3 coincides with the axis of the converging lens 20 and the symmetrical center line of the metal sheet 25; the workpiece mold s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com