A production process that effectively improves the pass rate of cemented carbide round knife blanks

A cemented carbide and production process technology, which is applied in the field of production process to effectively improve the pass rate of cemented carbide round knife blanks, can solve the problems affecting the pass rate of cemented carbide blanks, poor mixing effect, etc., to ensure forming and compactness The effect of high degree, sufficient mixing, and guaranteed pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

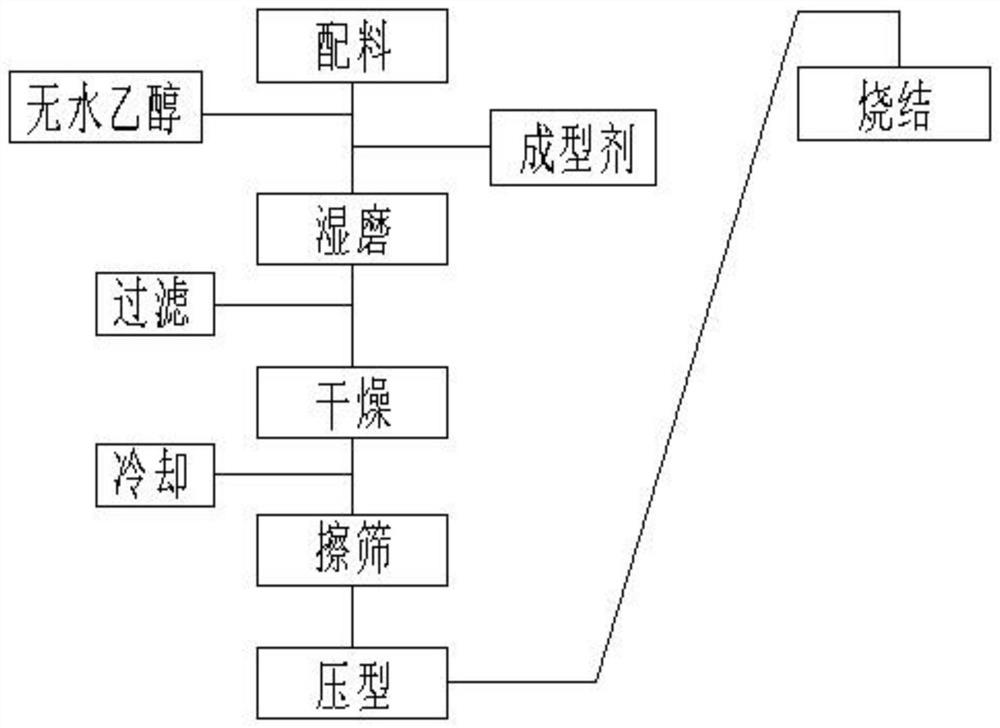

[0040] combine Figure 1 to Figure 4 As shown, the present invention proposes a production process that effectively improves the pass rate of cemented carbide round cutter blanks.

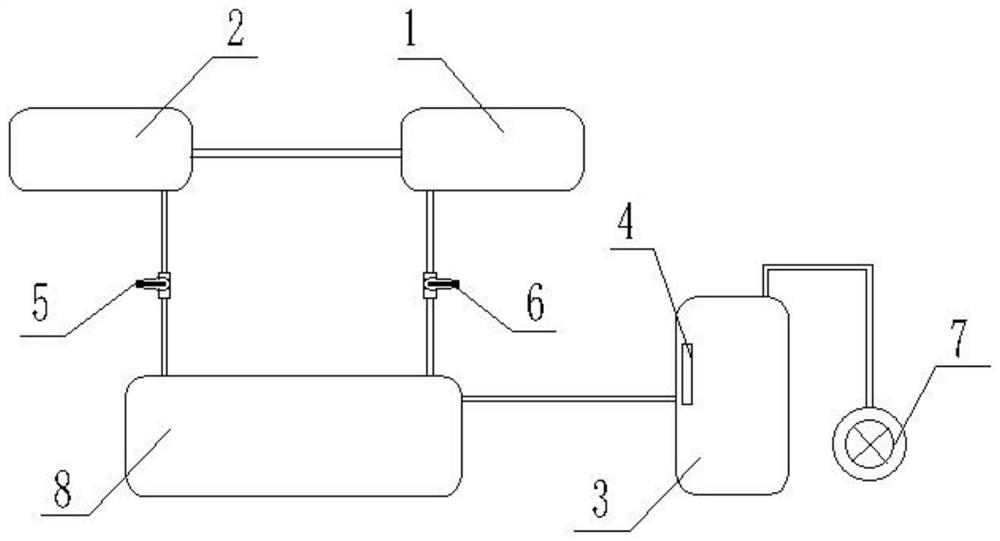

[0041] The water inlet and the water outlet of the hot water heating device communicate with the water outlet and the water inlet of the double-helical mixer through the first pipeline and the second pipeline respectively, and the first switching valve and the second valve are respectively arranged in the first pipeline and the second pipeline. Two switching valves; the air inlet of the ethanol recovery device communicates with the double-helix mixer through a pipeline, and an alcohol detector is arranged at the air inlet; the air suction port of the vacuum generator communicates with the air outlet of the ethanol recovery device through a pipeline.

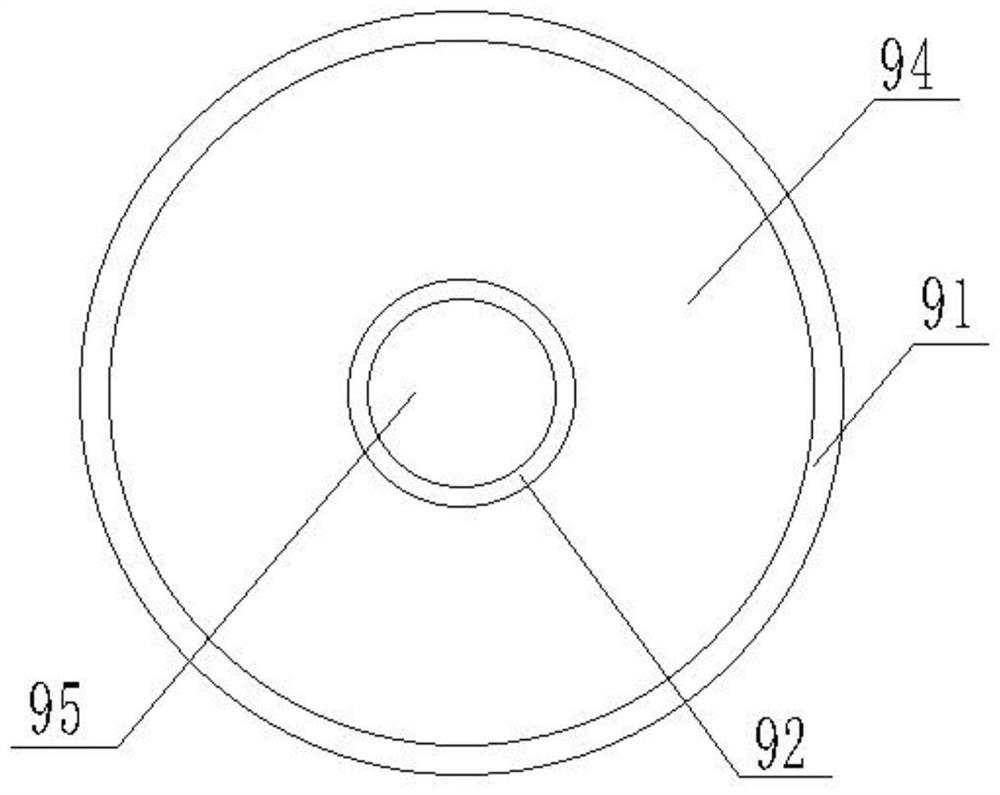

[0042] The graphite material boat includes an outer boss, a limit disc and an inner boss; the height of the outer boss is 3.5mm greater than the height...

Embodiment 2

[0060] The difference with embodiment 1 is:

[0061] Adjust the water outlet direction of the first switch valve 5 and the water inlet direction of the second switch valve 6 to reversely feed cold water at 10°C into the double helix mixer 8, and simultaneously feed argon gas and prefabricated water into the double helix mixer 8. The precipitates are in direct contact with the prefabricated precipitates inside to cool down to 45°C.

[0062] It is measured that the pass rate of the finished blank reaches 99.7%, and the hardness (HRA) of the finished blank is 93.2, and the strength (TRS) is 3013N / m 3 , the proportion of recovered paraffin was 2.27%, and the recovery rate was 98.69%. It shows that this process can significantly improve the qualification rate of raw materials to make flat blanks, and at the same time, the strength and strength are slightly improved compared with the previous process, which can effectively avoid the oxidation of the granular mixture during the proc...

Embodiment 3

[0064] The difference with embodiment 1 and 2 is:

[0065] In step B, when the reclaimed material is wet-milled, the prefabricated mixed material and the remaining absolute ethanol are added to the ball mill for wet grinding for 24 hours, and then the molding agent is added for wet grinding for 12 hours.

[0066] Through the reasonable wet grinding time of recycled materials, the corresponding ideal structure can be achieved at the same time, and the production cost can be greatly reduced. It is measured that the pass rate of the finished blank reaches 99.6%, and the hardness (HRA) of the finished blank is 92.2, and the strength (TRS) is 2997N / m 3 , the proportion of recovered paraffin was 2.278%, and the recovery rate was 99.01%. It shows that this kind of process can significantly improve the pass rate of finished blanks for recycled materials, and at the same time, the strength and strength are slightly improved compared with the previous process, and the recovery rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com