Milling chatter online detection method based on power spectral entropy difference

A technology for milling chatter and detection method, which is used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc. Sensitivity, increased sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The milling chatter online detection method based on power spectrum entropy difference of the present invention comprises the following steps:

[0037] (1) Signal collection:

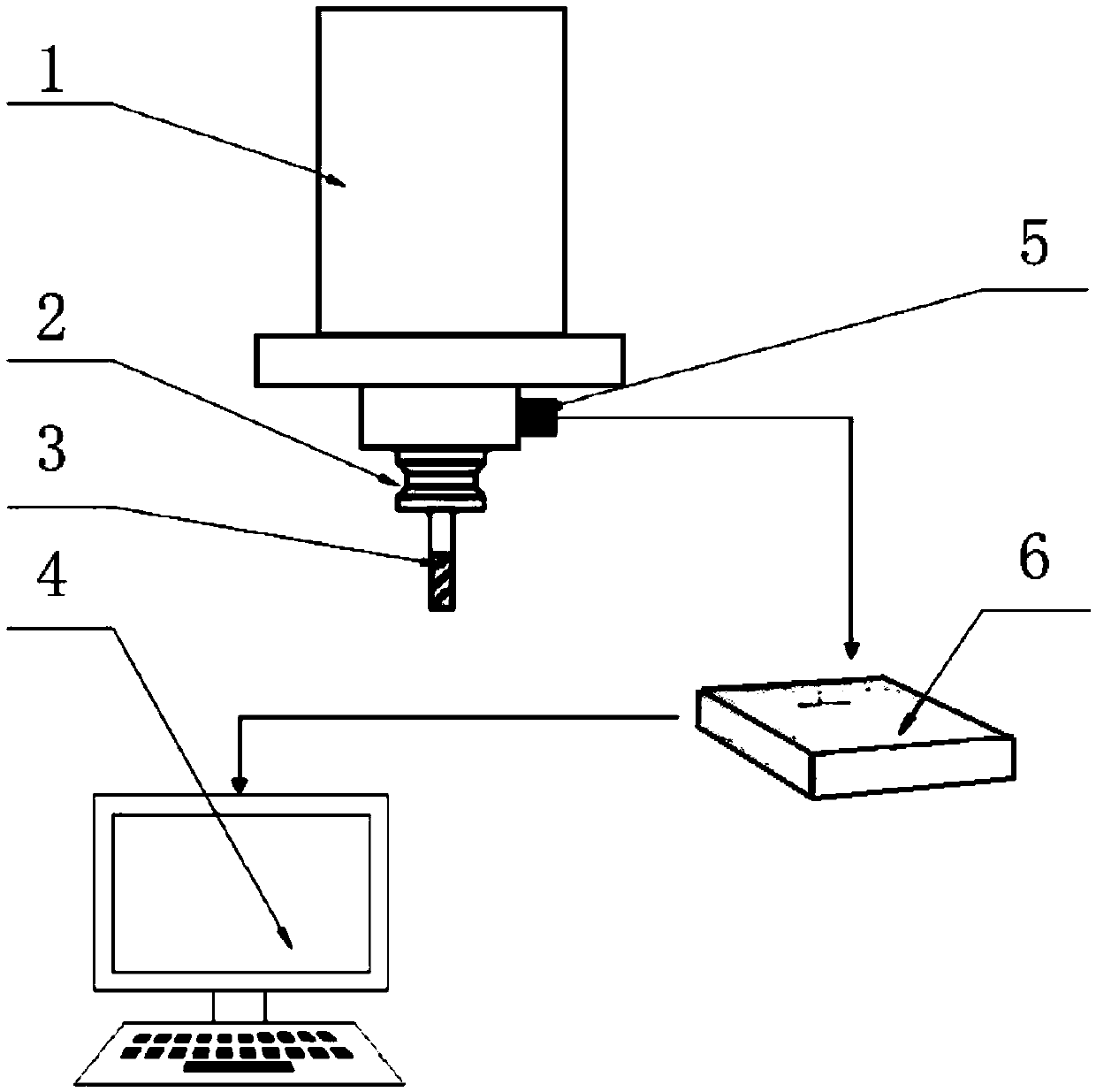

[0038] Such as figure 1 As shown, the milling cutter 3 is clamped and installed on the main shaft 1 by the tool handle 2, and the three-way acceleration signal sensor 5 is installed on the end of the main shaft 1. The parameters of the three-way acceleration signal sensor 5 are shown in Table 1. The three-way acceleration signal sensor 5 Cooperate with data acquisition card 6, the parameter of data acquisition card 6 is as shown in table 2, to acceleration signal sensor 5 and data acquisition card 6 are used for gathering the acceleration signal in the milling process, the acceleration signal that gathers is with X=[x 1 ,x 2 ,...,x n ] represents, n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com