A kind of magnetic material 3D printing equipment

A magnetic material, 3D printing technology, applied in the field of material processing, can solve the problems of 3D printing complex magnetic circuit devices not fully exerted, lack of magnetic material printing equipment, large gap in magnetic performance of magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

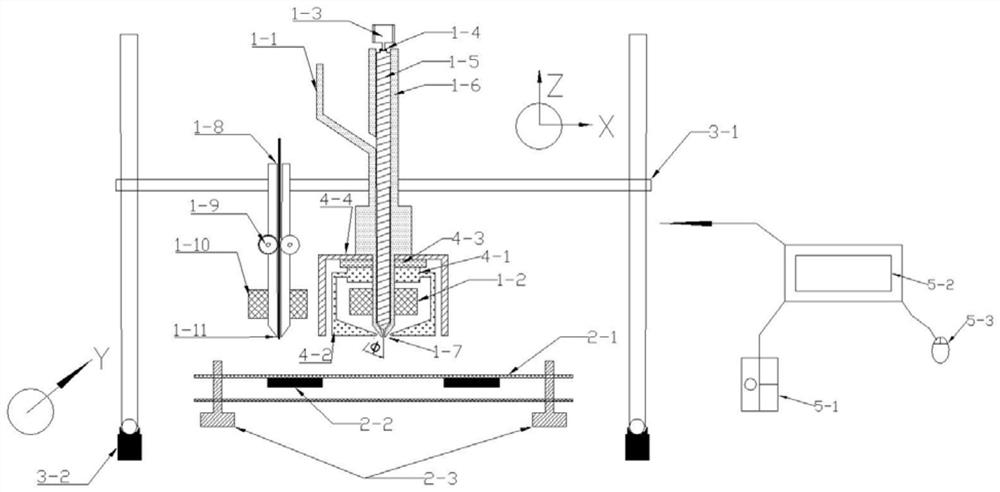

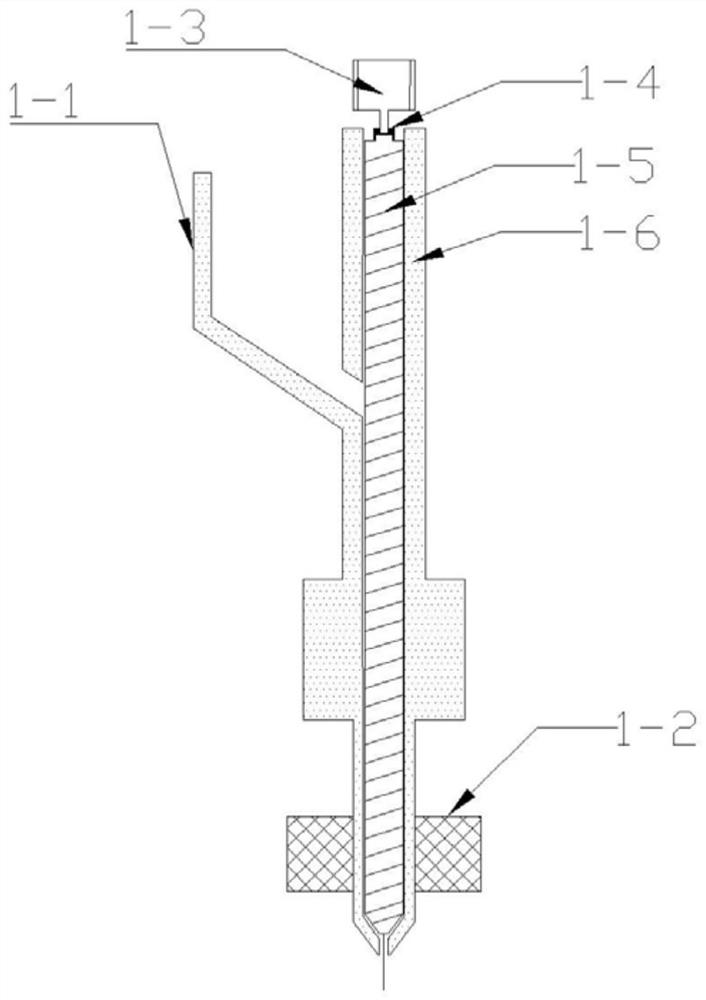

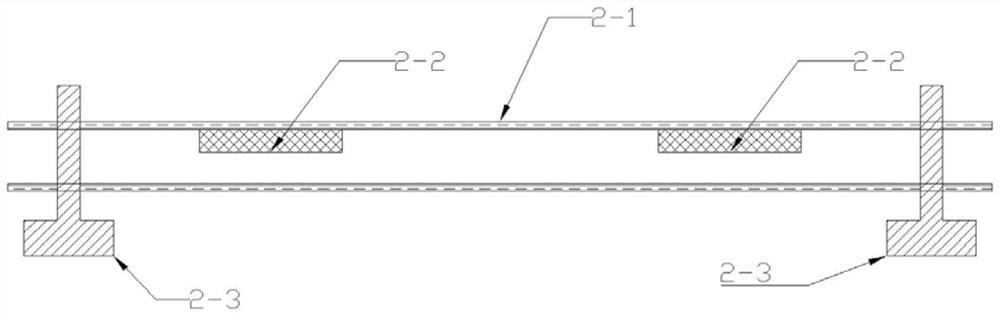

[0064] figure 1 It is a structural schematic diagram of the magnetic material 3D printing equipment of the present invention. The whole equipment includes five parts: extrusion mechanism 1, forming platform 2, displacement mechanism 3, magnetization device 4 and control unit 5. The extrusion mechanism 1 includes a feeding part 1-1, a heating part 1-2, an extrusion motor 1-3, a coupling 1-4, an extrusion screw 1-5, a sleeve 1-6, and a forming part 1. -7. Material guide pipe 1-8, wire feeding gear 1-9, heater 1-10 and extrusion head 1-11; forming platform 2 includes printing platform 2-1, heating device 2-2 and leveling device 2 -3; displacement mechanism 3 includes up, down, left, and right motion control 3-1, front and rear motion control 3-2; The cover 4-4; the control unit 5 includes a controller 5-1, a display 5-2, and an input terminal 5-3.

[0065] Specifically, the extrusion mechanism is responsible for accumulating raw materials to a specific place as required, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com