Environmental block embossing marking device

A marking device and block technology, which is applied in stamping, printing, etc., can solve the problems that the marking roller is easy to stick to the body fragments, the structure is huge, and the marking time is unclear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

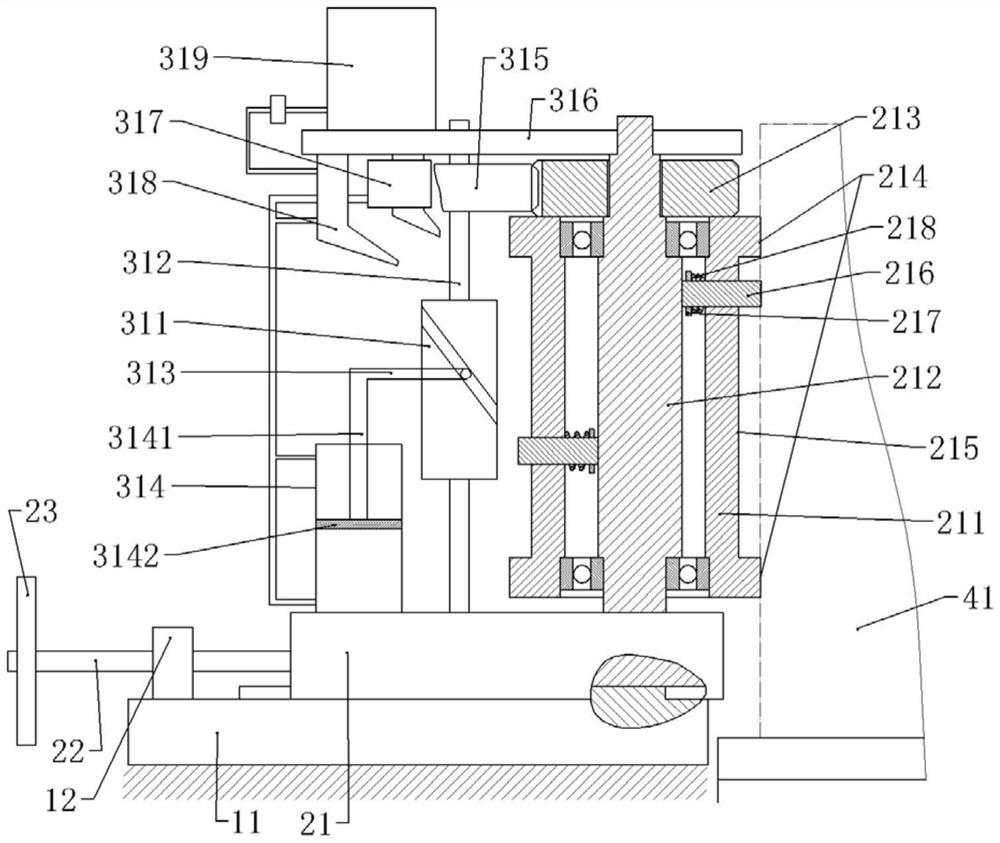

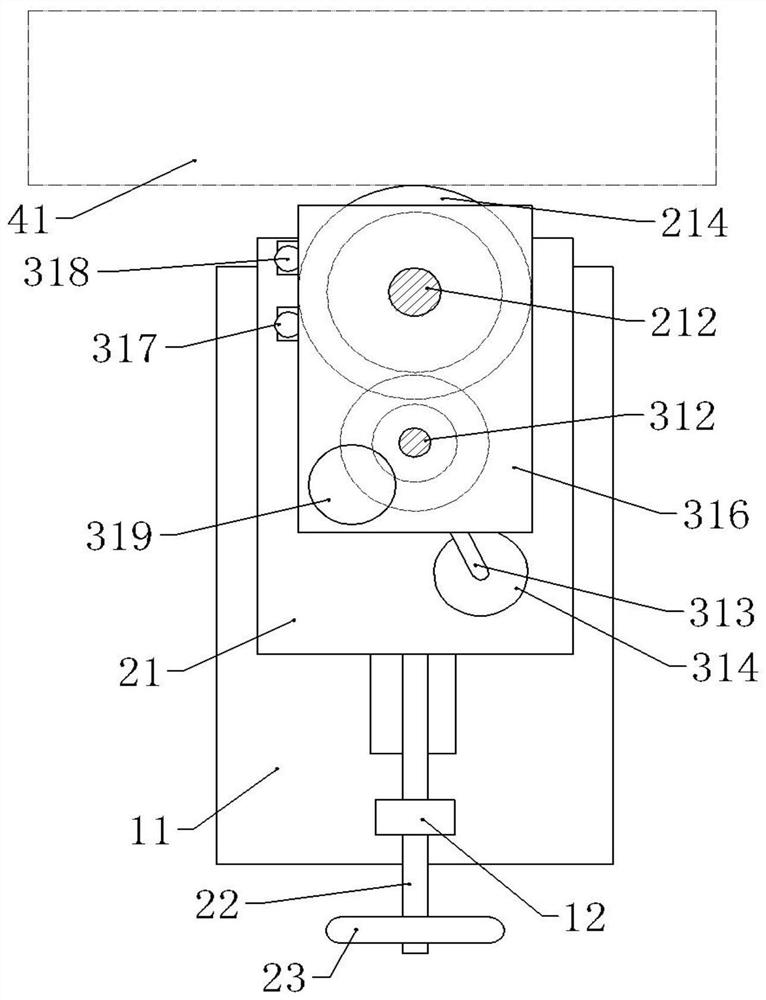

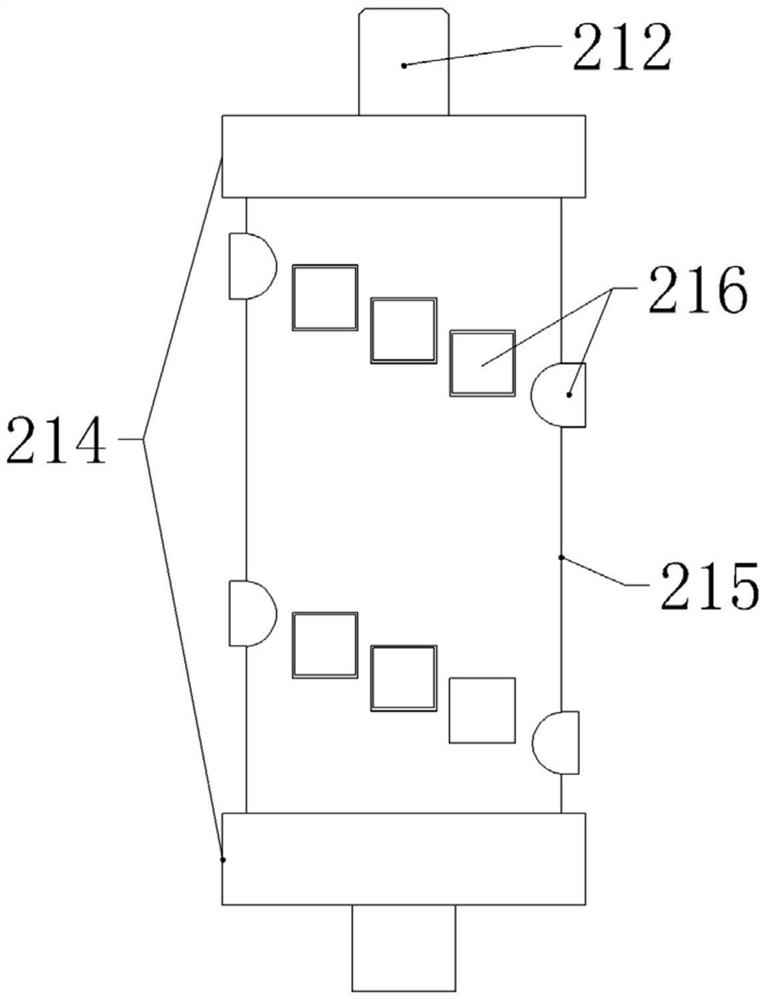

[0023] The reference signs in the drawings of the description include: the base plate 11, the base 12, the moving plate 21, the stamping cylinder 211, the camshaft 212, the driving gear 213, the friction part 214, the printing part 215, the stamping block 216, the limit block 217, compression spring 218, cylindrical cam 311, transmission shaft 312, driven rod 313, gas cylinder 314, piston rod 3141, piston 3142, driven gear 315, connecting plate 316, gas nozzle 317, sprayer 318, water tank 319, threaded rod 22, hand wheel 23, green body 41.

[0024] The embodiment is basically as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 Shown:

[0025] The embossing and marking device for environmentally friendly blocks includes a base plate 11, an embossing mechanism and a cleaning mechanism. The base plate 11 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com