Control method for engine electric heating type catalytic converter

A control method and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased fuel consumption, poor timeliness, and inability to realize catalytic conversion of emissions during the cold start stage, and achieve improved electric heating, reasonable and effective The effect of controlling and shortening the ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment proposes a control method for an engine electric heating catalyst, which is used to accelerate the rapid ignition of the catalyst in the cold start and cold engine stages of the vehicle engine, so as to achieve reasonable and effective control of gas emissions.

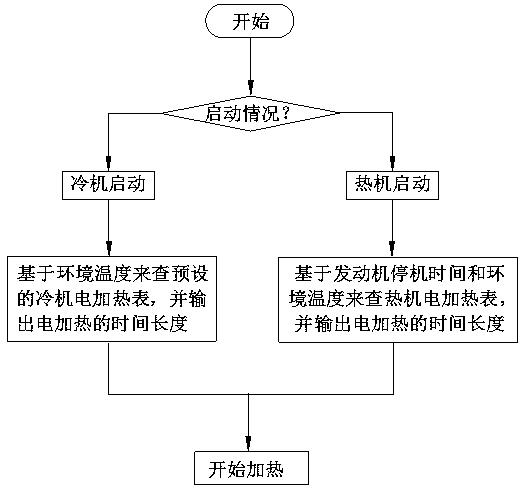

[0020] The control method of the electric heating type catalytic converter of the engine of the present embodiment is as follows: the engine control unit controls the on-off of the power supply of the electric heating catalytic converter through a relay; table to control the electric heating time of the electric heating catalyst.

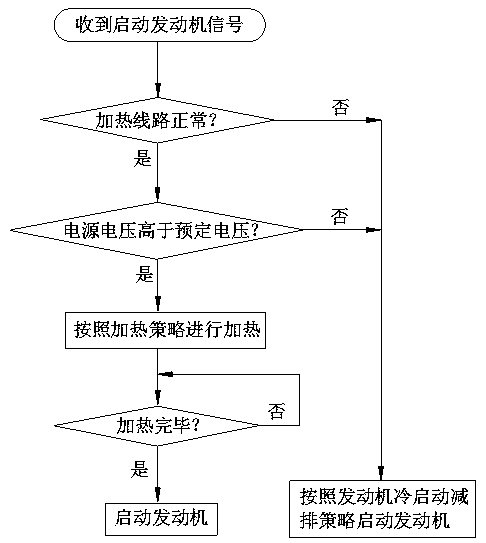

[0021] Specific as figure 1 As shown, after the engine control unit receives the signal to start the engine, it first checks whether the heating circuit is normal. Large currents may cause safety hazards. Specifically, an open circuit or a short circuit of the heating line will show a different voltage signal at the engine control unit, based on which it can be reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com