Shell-and-tube type water condenser with single system

A water condenser, shell-and-tube technology, which is applied in the field of single-system shell-and-tube water condensers, can solve the problems of poor heat exchange effect, dust and sludge in the condensing plate group, and difficult to remove scale, so as to increase heat exchange ability, guaranteed sealing effect, wide adjustment range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

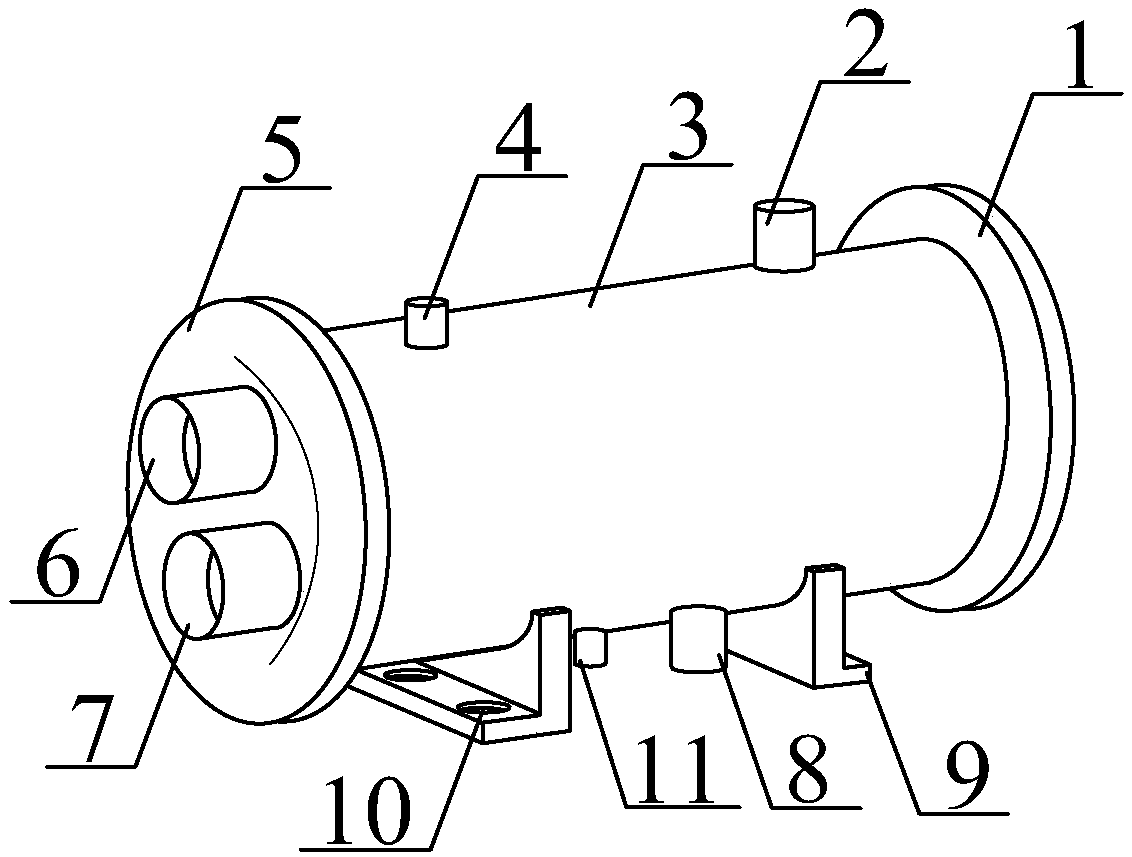

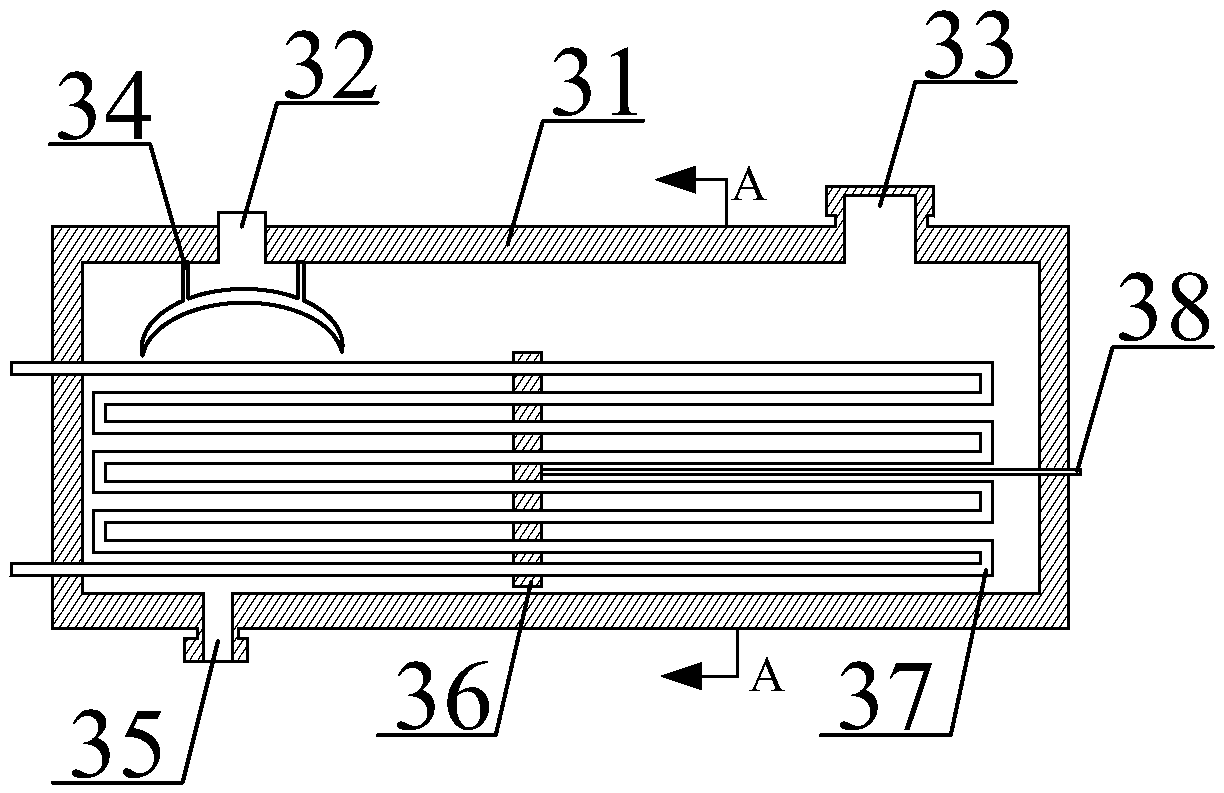

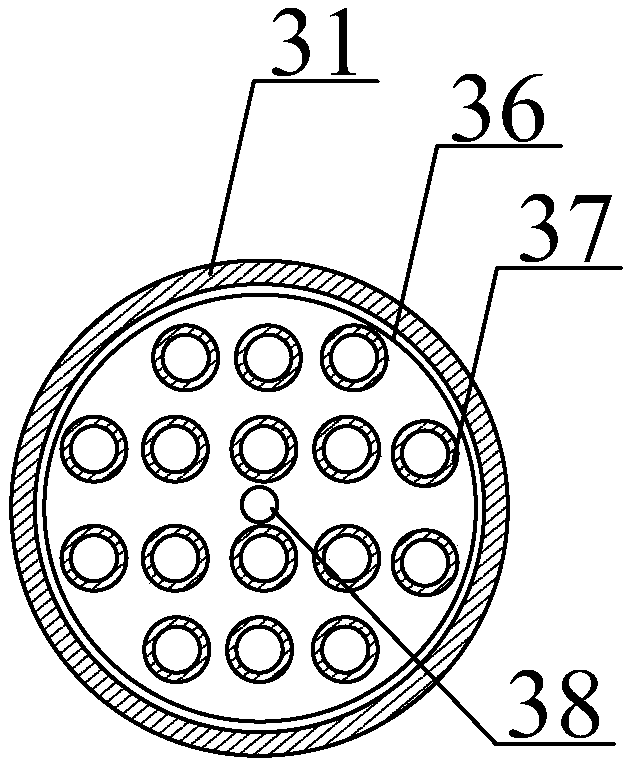

[0028] Such as Figure 1-5 As shown, the present invention provides a technical solution: a single-system shell-and-tube water condenser, including a right end cover, a condensed water inlet joint, a condenser assembly, a steam port end cap, a left end cover, a condensing agent gas inlet joint, a condenser agent liquid outlet joint, condensate water outlet joint, frame seat, installation hole and drain port, the right end cover is connected with the right end of the condenser assembly through threads; the condensate water inlet joint is welded on the upper right side of the condenser assembly , and communicate with the inside of the condenser assembly; the steam port end cap is fastened above the steam discharge port; the left end cap is threaded to the left end of the condenser assembly; the condensing agent gas inlet joint and the condensing The solvent liquid outlet joint is welded on one side of the right end cover sequentially from top to bottom; the condensed water outle...

Embodiment 2

[0030] A single-system shell-and-tube water condenser, including a right end cover, a condensed water inlet joint, a condenser assembly, a steam port end cap, a left end cover, a condensing agent gas inlet joint, a condensing agent liquid outlet joint, a condensed water outlet joint, and a machine frame, mounting hole and drain port, the right end cover is threadedly connected with the right end of the condenser assembly; the condensed water inlet joint is welded on the upper right side of the condenser assembly and communicates with the inside of the condenser assembly; The steam port end cap is fastened above the steam discharge port; the left end cap is threadedly connected to the left end of the condenser assembly; the condensing agent gas inlet joint and the condensing agent liquid outlet joint are welded on the One side of the right end cover; the condensed water outlet joint is welded on the bottom of the condenser assembly and penetrates with the inside of the condenser...

Embodiment 3

[0033]A single-system shell-and-tube water condenser, including a right end cover, a condensed water inlet joint, a condenser assembly, a steam port end cap, a left end cover, a condensing agent gas inlet joint, a condensing agent liquid outlet joint, a condensed water outlet joint, and a machine frame, mounting hole and drain port, the right end cover is threadedly connected with the right end of the condenser assembly; the condensed water inlet joint is welded on the upper right side of the condenser assembly and communicates with the inside of the condenser assembly; The steam port end cap is fastened above the steam discharge port; the left end cap is threadedly connected to the left end of the condenser assembly; the condensing agent gas inlet joint and the condensing agent liquid outlet joint are welded on the One side of the right end cover; the condensed water outlet joint is welded on the bottom of the condenser assembly and penetrates with the inside of the condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com