A copper foil cleaning and drying device

A drying device and technology of copper foil, applied in the field of copper foil, can solve the problems of copper foil oxidation and corrosion, reduce copper foil quality, incomplete cleaning, etc., and achieve the effects of reducing cleaning pressure, improving loading and unloading efficiency, and reducing residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

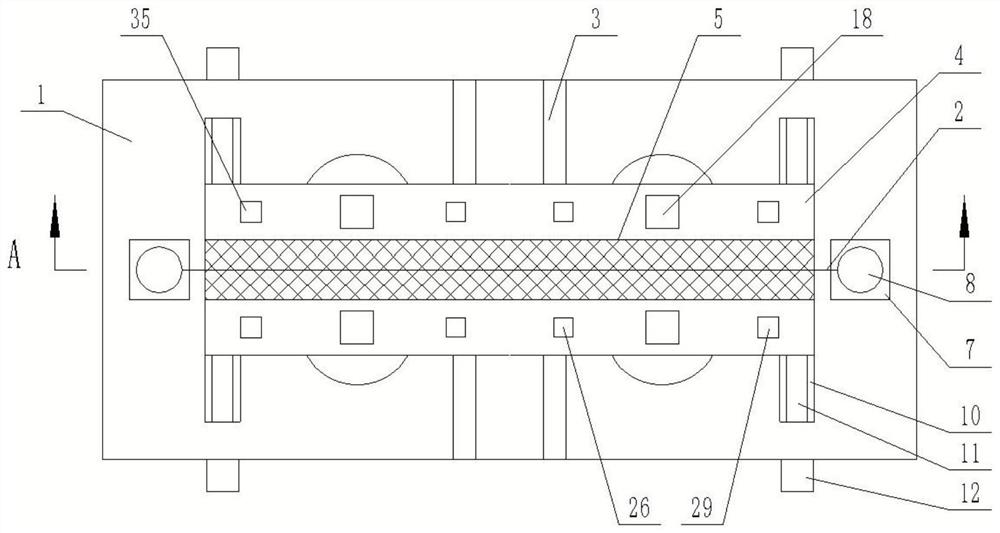

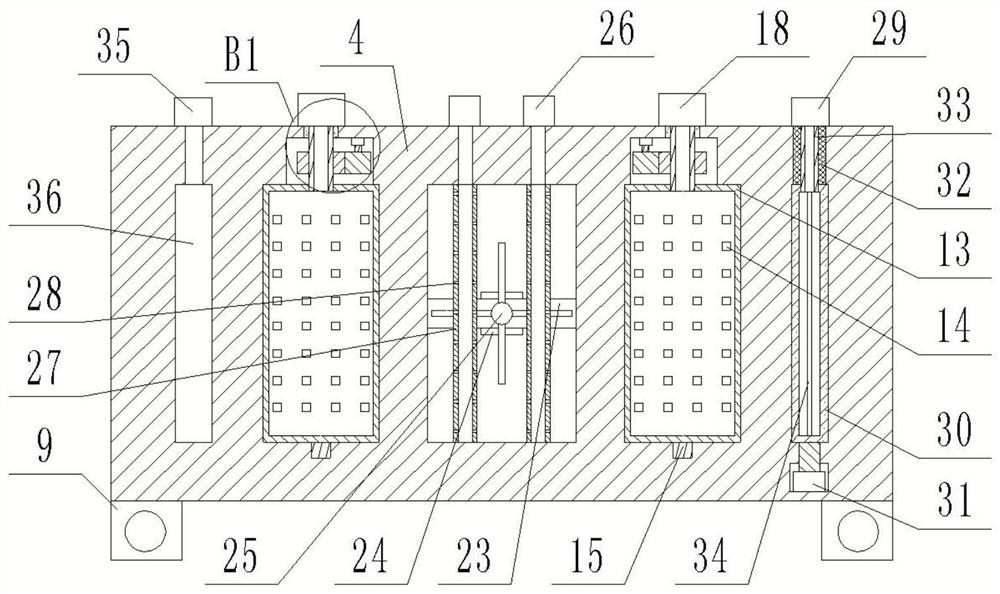

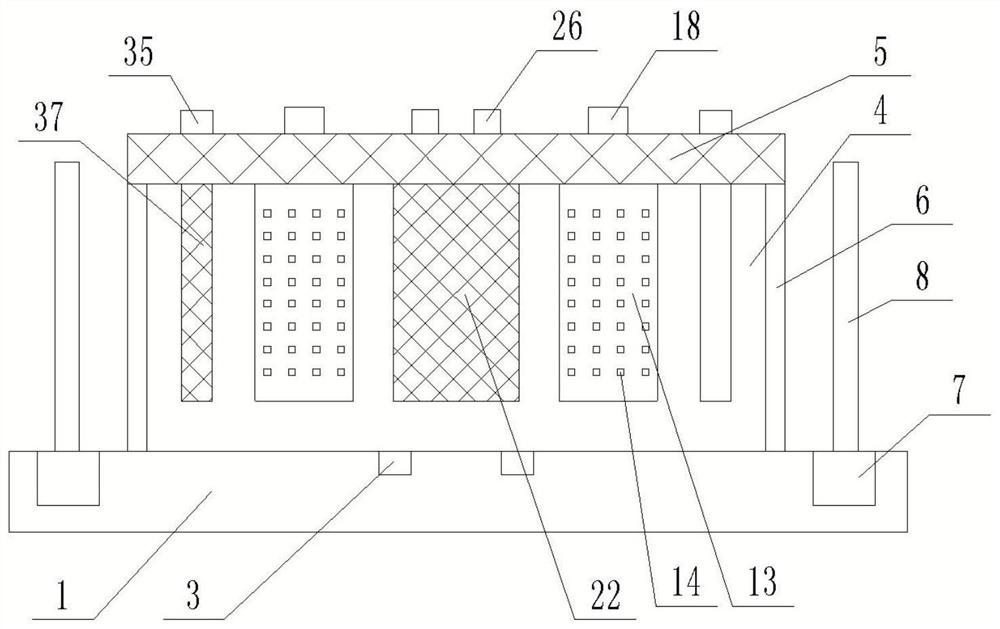

[0025] refer to Figure 1-4 , This embodiment provides a copper foil cleaning and drying device, including: a bottom plate 1, two cleaning mechanisms are arranged on the top surface of the bottom plate 1, a winding mechanism is arranged on both sides of the bottom plate 1, and a copper foil is arranged between the two winding mechanisms. Body 2, the two winding mechanisms rotate in the same direction, the two cleaning mechanisms are arranged symmetrically with respect to the copper foil body 2, and the copper foil body 2 is arranged between the two cleaning mechanisms, the bottom surface of the cleaning mechanism is slidingly connected to the top surface of the bottom plate 1, and the top surface of the bottom plate 1 A number of water guide channels 3 are vertically opened;

[0026] The cleaning mechanism includes a cleaning plate 4. Slide assemblies are respectively arranged on both sides of the bottom surface of the cleaning plate 4. Two adsorption assemblies are arranged o...

Embodiment 2

[0043] refer to Figure 5 , This embodiment provides a water-absorbing component to prevent a large amount of sewage entering the adsorption cylinder 13 from accumulating and causing secondary pollution.

[0044] The water absorption assembly includes a water suction pipe 38 and a water suction cylinder 39. The water suction pipe 38 and the water absorption cylinder 39 are arranged in the adsorption cylinder 13. Fixed connection, the peripheral wall of the adsorption cylinder 13 is provided with a number of water absorption holes 40 at equal intervals in the circumferential direction.

[0045] The water absorption hole 40 provided can achieve the effect of water absorption while inhaling air, and prevents sewage from accumulating in the inner cavity of the adsorption cylinder 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com