Water spraying tray type rotating-film deaerator

A technology of water spray tray and deaerator, which is applied in the direction of degassed water/sewage treatment, etc. It can solve the problems that the rotary membrane deaerator cannot deoxidize, and achieve the effects of saving resources, reducing corrosion, and enhancing welding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

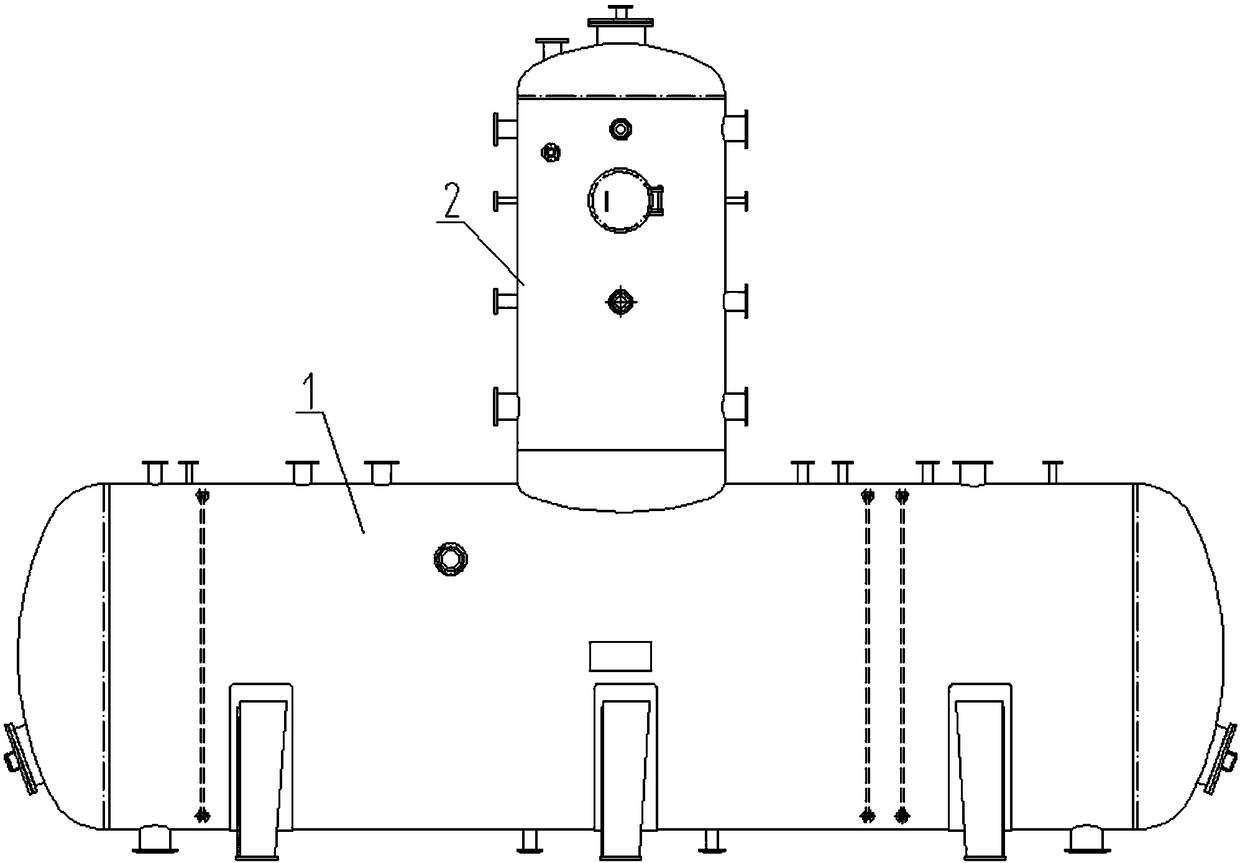

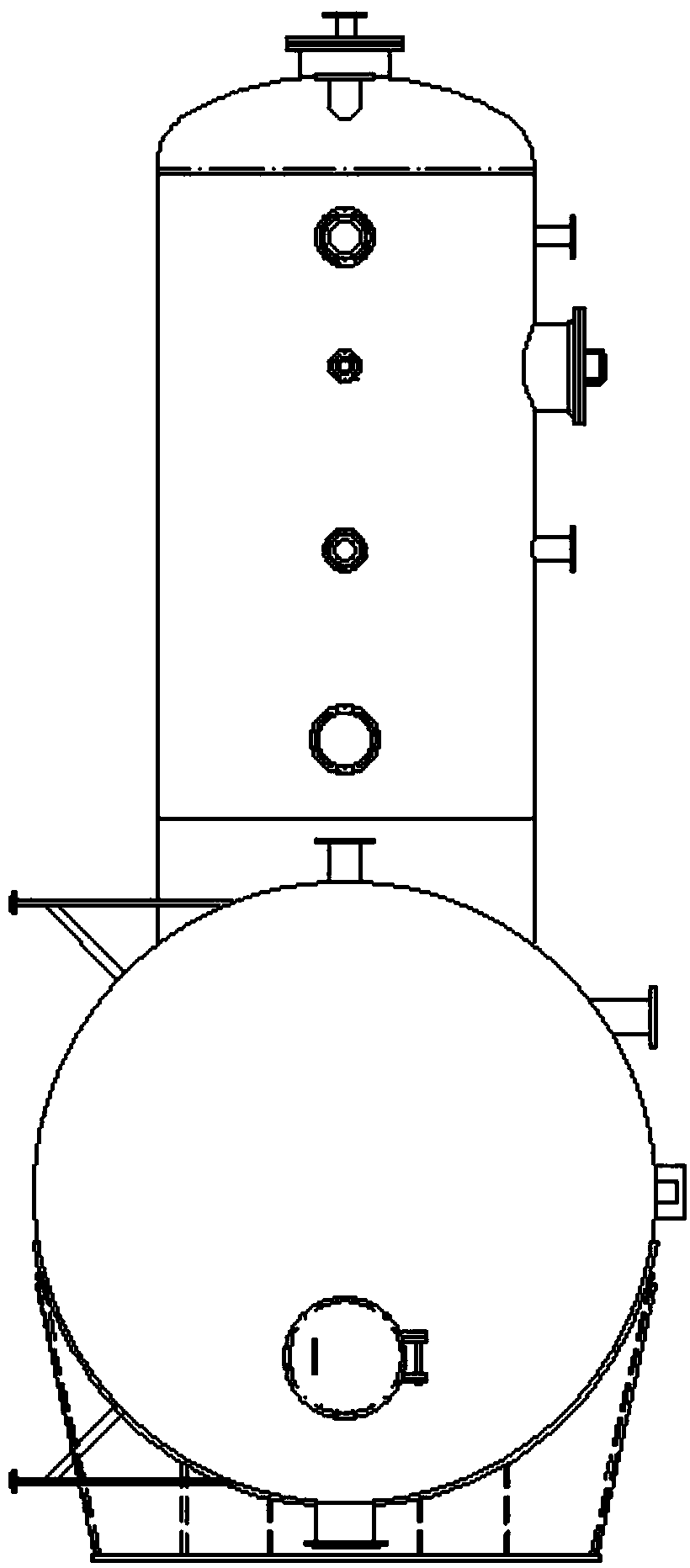

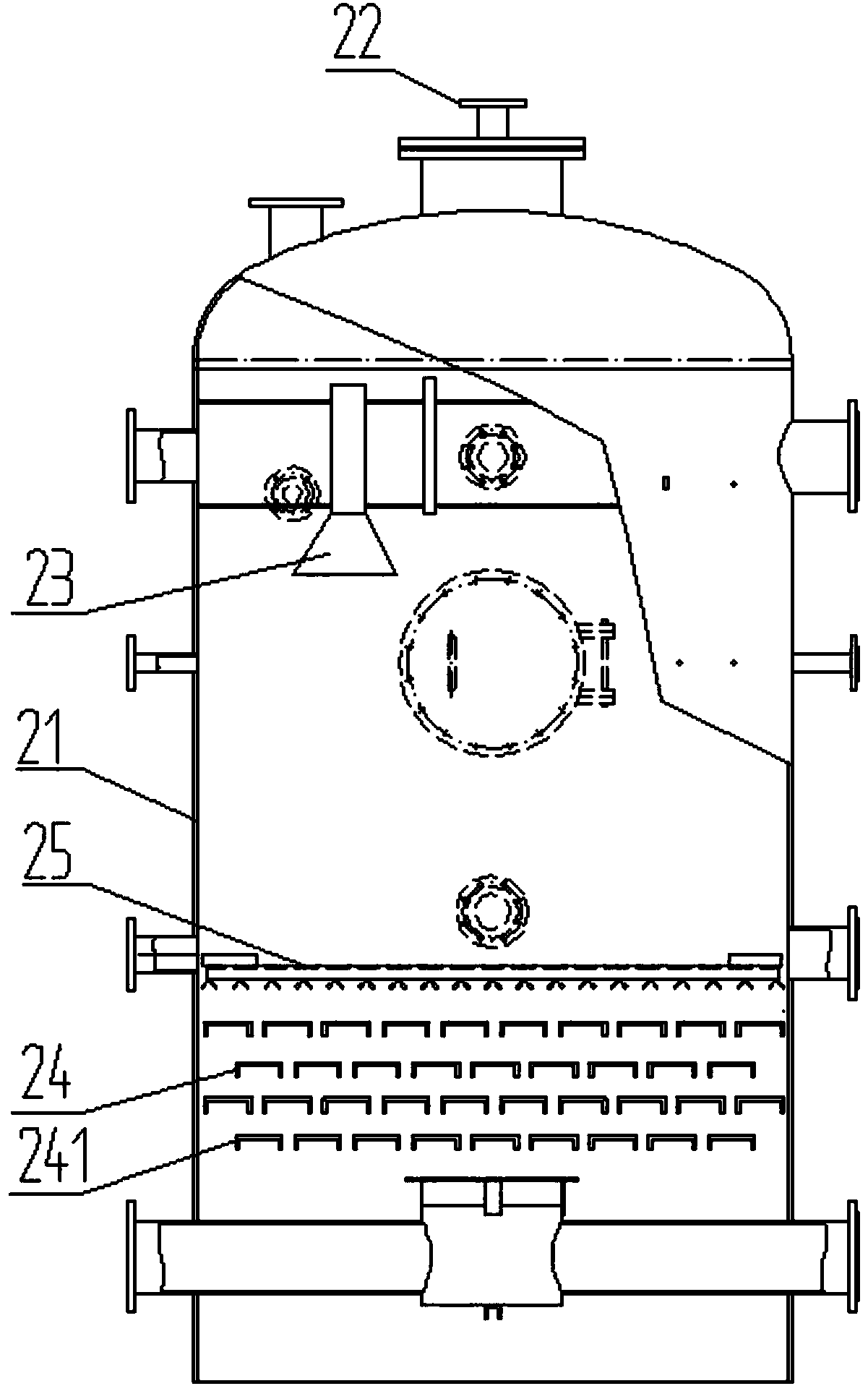

[0033] Figure 1 to Figure 3 It is an embodiment of the present invention. As shown in the figure, the water-spraying disc-type spinner deaerator includes a water tank 1 and a deaerator head 2. The deaerator head 2 includes a shell 21, a spinner set 23, a shower The water grate 25 is provided with a water spray tray 24 below the water spray grate 25, and the water spray tray 24 includes a multi-layer water spray plate 241, and two adjacent layers of water spray plates 241 are arranged crosswise, and the water spray plate 241 is connected to the shell 21. By setting the water spray tray 24, the deaerator can deoxygenate the feed water with large flow rate and fast flow rate. During the 24 process, it collides with the water spray plate 241 many times, so that the feed water is fully con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com