Operation environment pre-warning device

A working environment and early warning technology, applied in the circuit field, can solve problems such as signal frequency hopping, electromagnetic interference, threats to worker safety and factory efficiency, etc., to achieve the effect of increasing switching speed and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

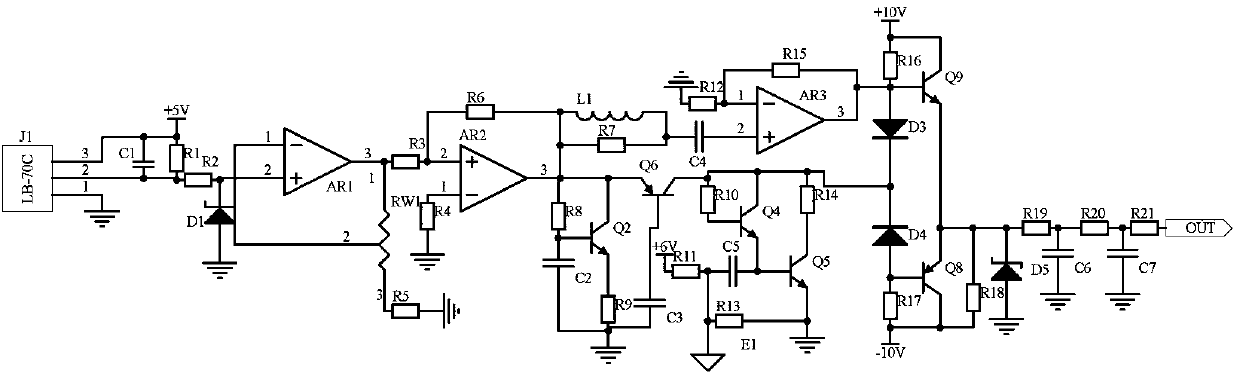

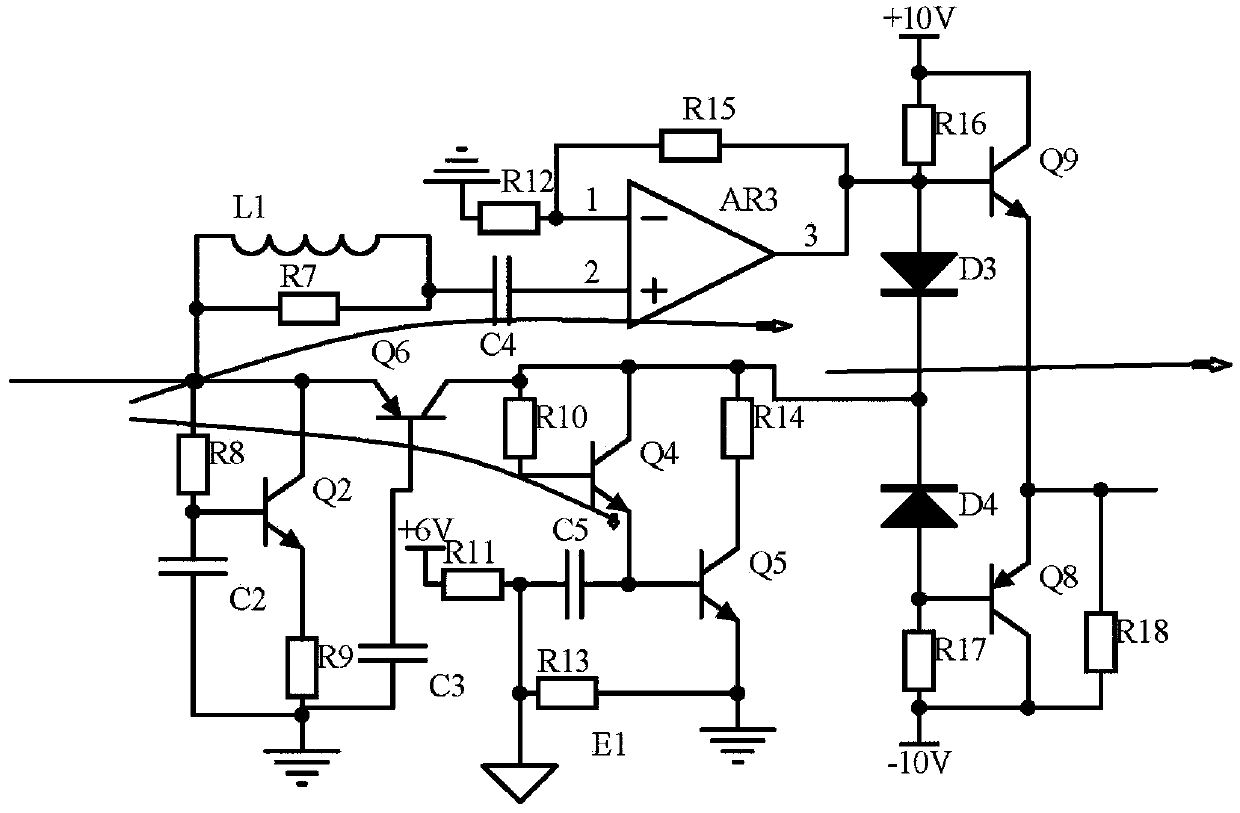

[0014] Embodiment 1, the working environment early warning device includes a smoke signal acquisition circuit, a frequency division push-pull circuit and a filter output circuit. The smoke signal acquisition circuit uses the smoke signal collector J1 model LB-70C to collect the smoke signal of the factory working environment. Use the operational amplifier AR1, the operational amplifier AR2 and the variable resistor RW1 to form a voltage conversion circuit to convert the current signal into a voltage signal. The frequency division push-pull circuit is divided into two channels to receive the output signal of the smoke signal acquisition circuit, and one circuit uses the inductor L1 and Resistor R7 and capacitor C4 form a compound circuit to filter out high-frequency noise in the signal. At the same time, the operational amplifier AR3 is used to amplify the signal in phase. The second circuit uses the triode Q1, resistor R8 and capacitor C2 to form a delay circuit to delay the sig...

Embodiment 2

[0017] Embodiment 2, on the basis of Embodiment 1, the filter output circuit uses resistors R19, resistors R20, capacitors C6, and capacitors C7 to form an RC circuit to filter and output, to filter out clutter in the signal, and to stabilize the voltage with the regulator tube D5. That is to say, it is the trigger signal of the working environment early warning module. When the dust signal collector J1 collects abnormal smoke and dust signals in the factory working environment, the signal is a high-level signal, which can trigger the work alarm of the working environment early warning module. The signal output port and the working environment The early warning module is connected. When the dust signal collector J1 collects the dust signal in the factory working environment normally, the signal is a low-level signal, which cannot trigger the work of the early warning module of the working environment. One end of the resistor R19 is connected to the negative pole of the voltage r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com