Crack-contained real sandstone core physical simulation and oil displacement effect evaluation method

A technology of physical simulation and evaluation method, which is applied in water resources evaluation, analysis by nuclear magnetic resonance, instruments, etc. It can solve problems that do not involve the evaluation method of oil displacement effect with fractures, and achieve the effect of authentic and reliable experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

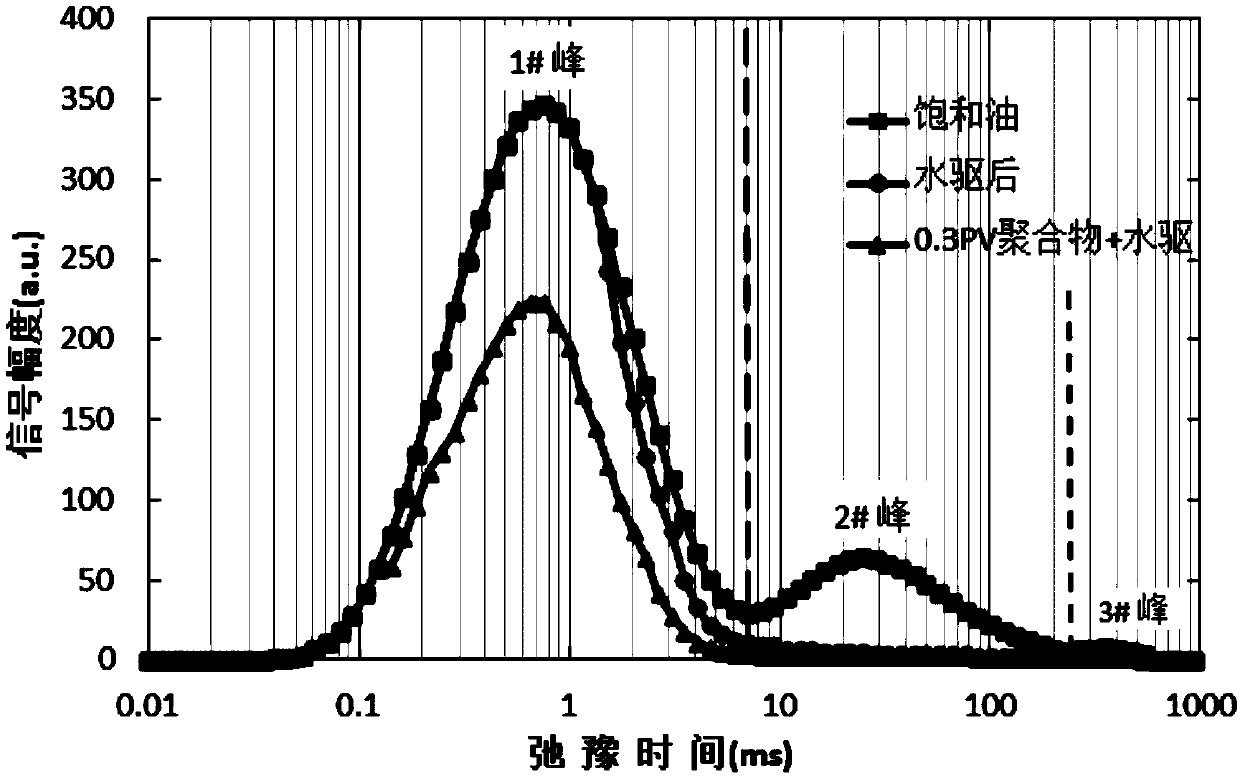

Embodiment 1

[0034] The physical simulation of real sandstone core with fractures and the evaluation method of oil displacement effect include the following steps:

[0035] Step 1: Select a real sandstone core with fractures with a diameter of 2.5cm and a length of 4.0cm, wash the oil and dry it; in addition, prepare Mn according to the salinity of the oilfield produced water 2+ Containing Mn with a concentration of 5000mg / L-8000mg / L 2+ The simulated formation water is used, and the simulated oil is prepared according to the crude oil viscosity of 2.0mPa.s under the oil field formation conditions;

[0036] Step 2: Vacuum the core sample and saturate it with Mn 2+ The simulated formation water was subjected to centrifugal treatment at a centrifugal speed of 9000r / min for 2 hours to remove movable water and establish irreducible water saturation;

[0037] Step 3: Weigh the rock core sample obtained in Step 2, and then place it in a vacuum pressure saturation device to saturate the simulate...

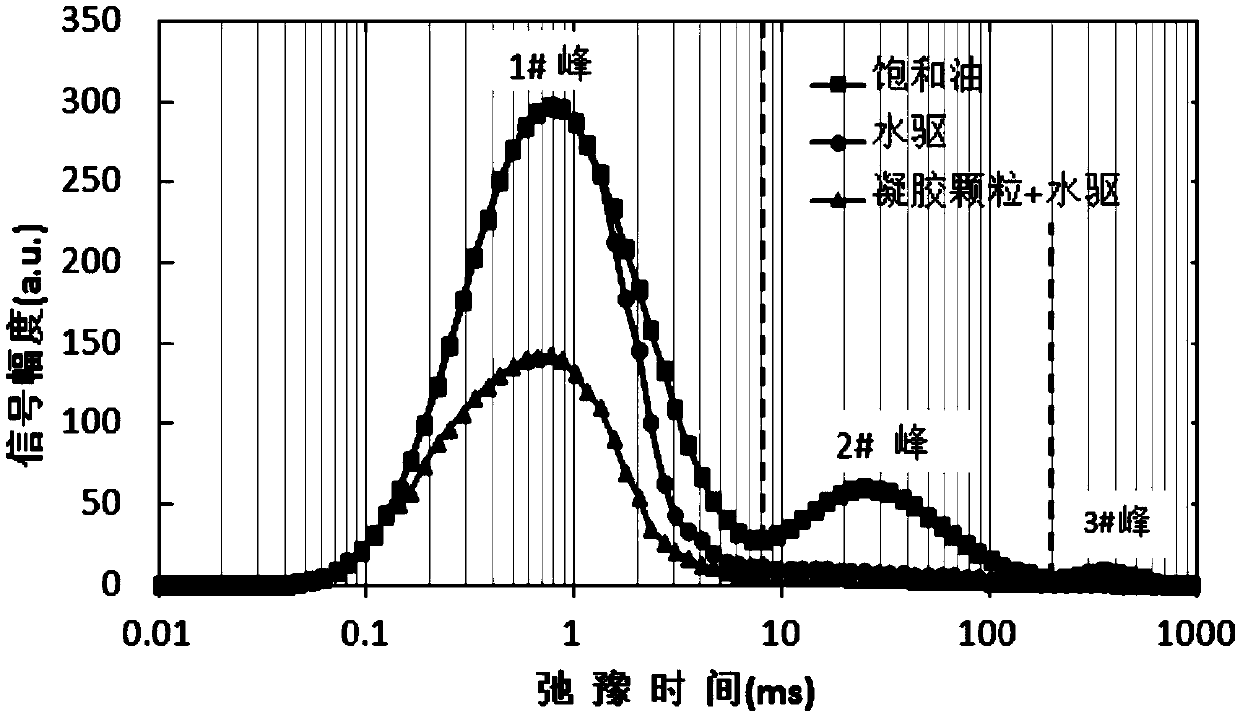

Embodiment 2

[0048] The physical simulation of real sandstone core with fractures and the evaluation method of oil displacement effect include the following steps:

[0049] Step 1: Select a real sandstone core with fractures with a diameter of 2.5cm and a length of 4.0cm, wash the oil and dry it; in addition, prepare Mn according to the salinity of the oilfield produced water 2+ Containing Mn with a concentration of 5000mg / L-8000mg / L 2+ The simulated formation water is prepared according to the crude oil viscosity of 1.8mPa.s under the oil field formation conditions to prepare the simulated oil;

[0050] Step 2: Vacuum the core sample and saturate it with Mn 2+ The simulated formation water was subjected to centrifugal treatment at a centrifugal speed of 9000r / min for 2 hours to remove movable water and establish irreducible water saturation;

[0051] Step 3: Weigh the rock core sample obtained in Step 2, then place it in a vacuum pressure saturation device, saturate the oil used in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com