Bipolar plate structure of fuel cell

A fuel cell and bipolar plate technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve problems such as multiple outlet opening areas, impact on fuel cell performance, and reduction of oxidant gas carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

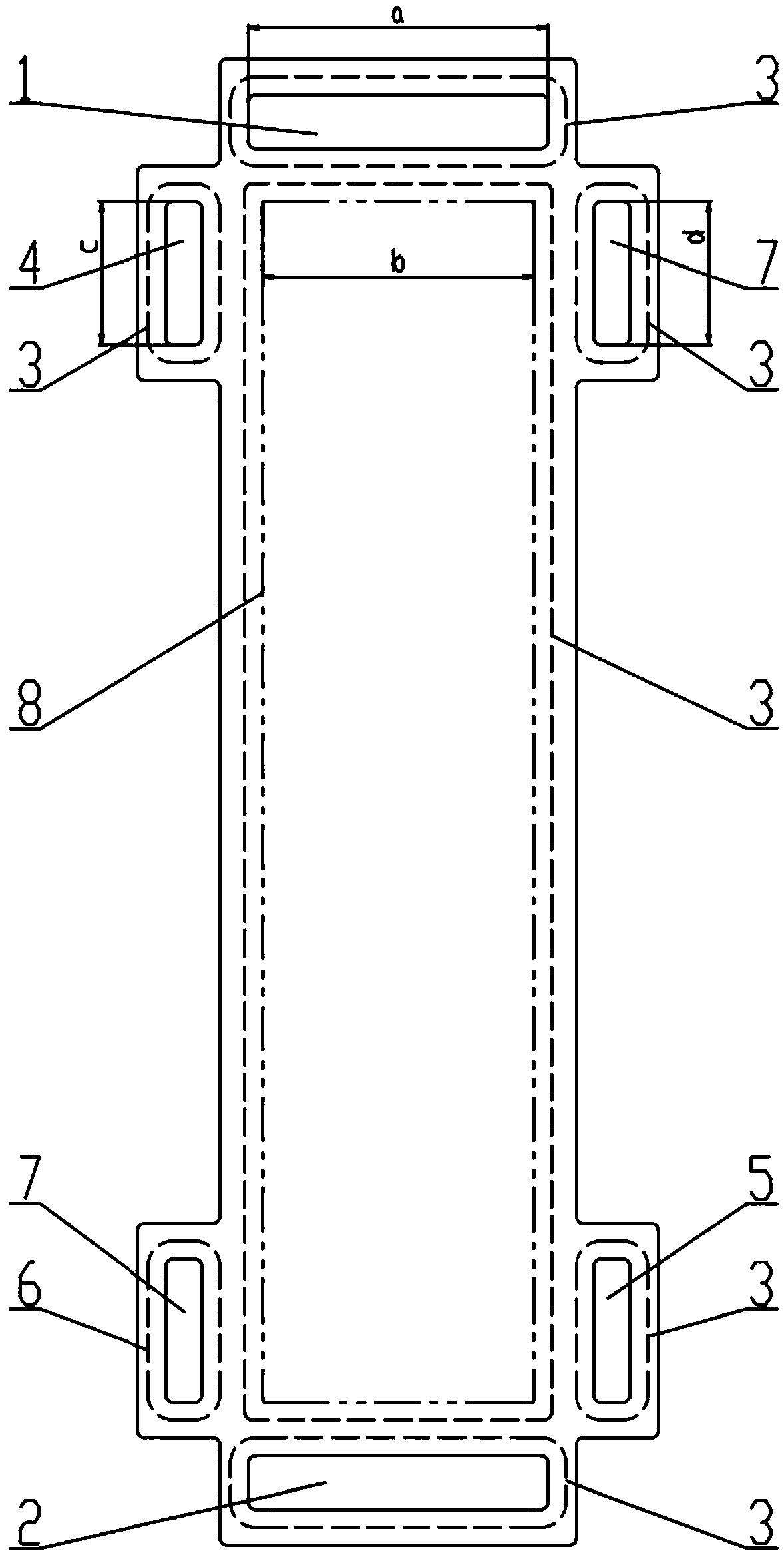

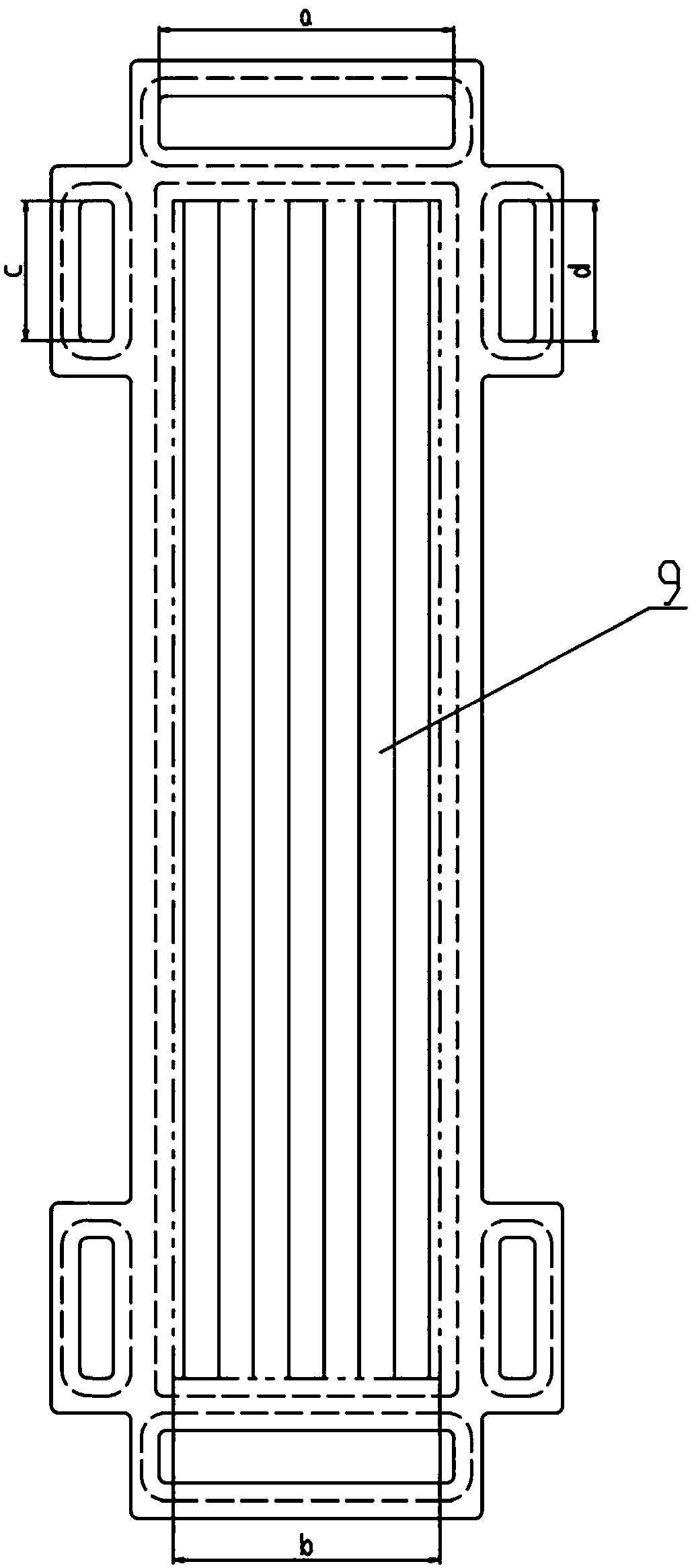

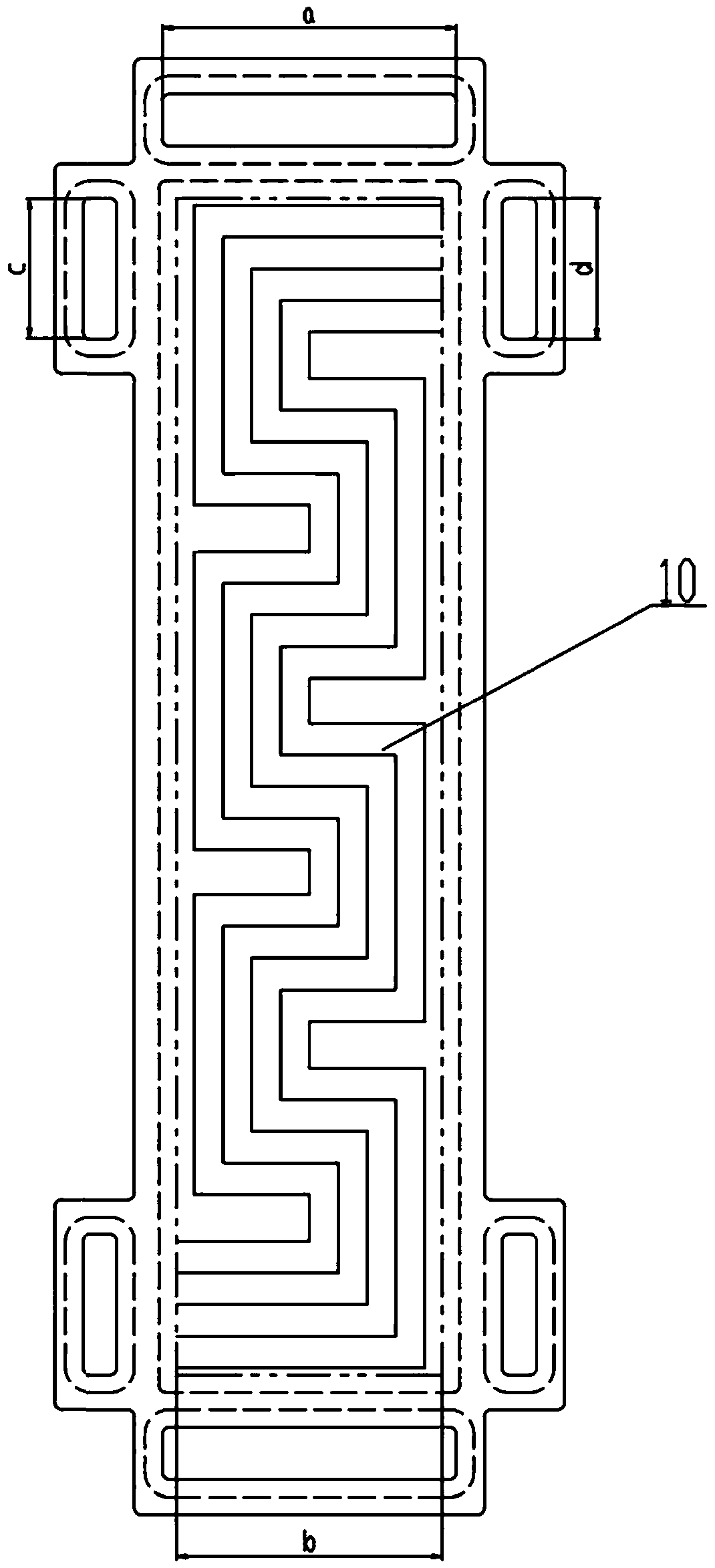

[0029] The layout of the fuel cell bipolar plate of the present invention includes the general arrangement of functional structures such as fuel cell flow field (including fuel gas flow field and oxidant gas flow field), fuel gas, oxidant gas, coolant and sealing structure on the fuel cell bipolar plate . The middle part of the fuel cell bipolar plate is the fuel cell flow field, which occupies most of the area of the fuel cell bipolar plate. The fuel cell flow field is rectangular, the oxidant gas flow field is on one side of the bipolar plate, and the fuel gas flow field is On the other side of the polar plate, the size, shape and position of the two flow fields are the same, that is, the projections of the oxidant gas flow field and the fuel gas flow field on the middle plane of the two flow fields are coincident; On both sides of the side, the oxidant gas inlet and outlet are respectively arranged. In the length direction of the side adjacent to the fuel cell flow field,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com