A five-phase permanent magnet motor direct torque control maximum torque current ratio control method

A maximum torque current, direct torque control technology, applied in motor control, motor generator control, control of electromechanical brakes, etc., can solve the problem of torque, current pulsation, table method, a large amount of offline work storage space, and motor parameter accuracy. Higher requirements, etc., to achieve the effect of the third harmonic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

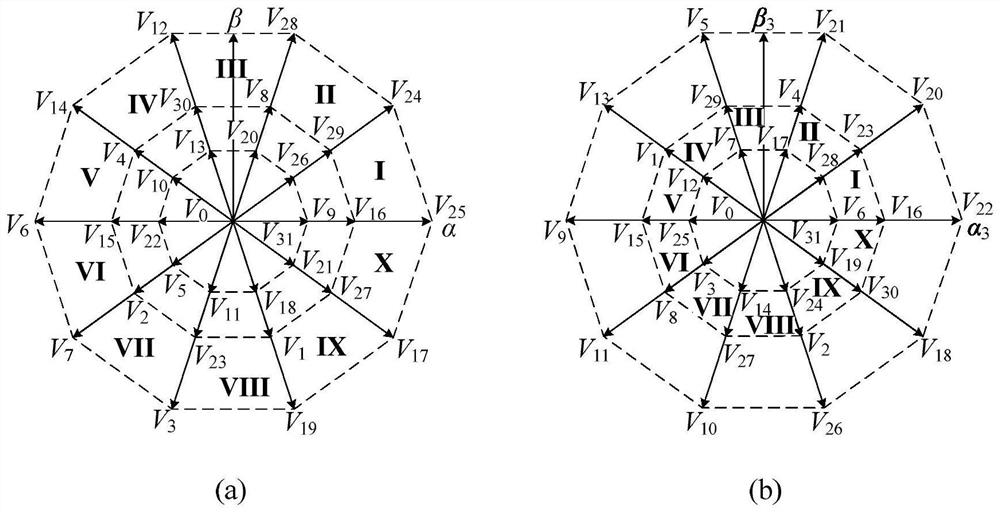

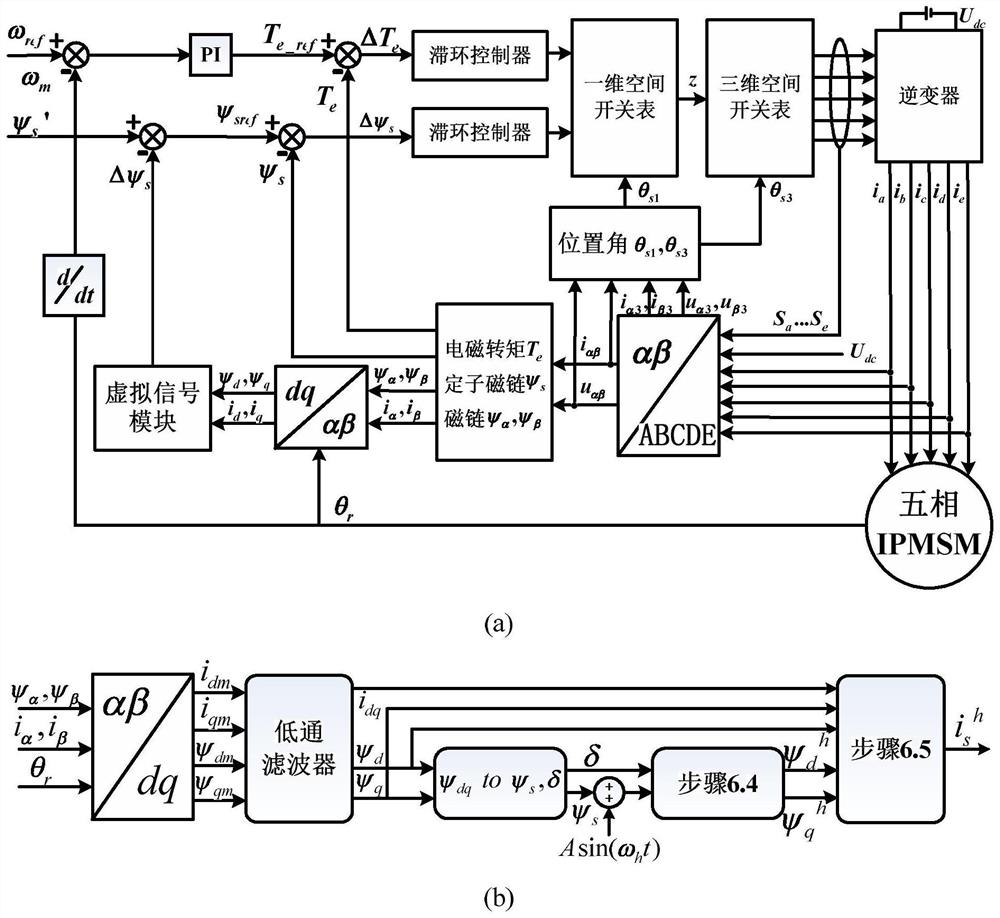

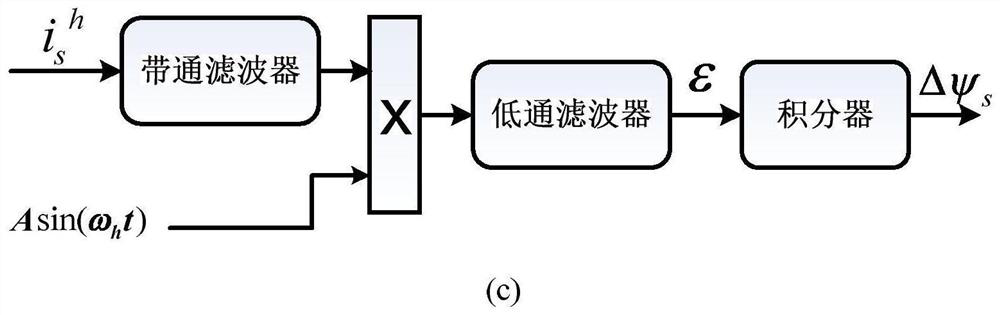

[0065] The specific embodiment mainly introduces the maximum torque current ratio control under DTC based on virtual signal injection, and its control block diagram is as follows figure 1 shown. The specific implementation manner and implementation effect of the embodiment will be described in detail below in conjunction with the accompanying drawings.

[0066] Step 1, detect the speed of the five-phase permanent magnet motor as the speed feedback of the motor ω m , the given speed ω ref and feedback speed ω m Comparing the speed error e of the motor r , using PI controller according to the speed error e r Calculate the reference torque of the five-phase permanent magnet motor, and the output of the PI controller is the reference torque T e_ref .

[0067] Step 2, use the current sensor to sample the current i of each phase of the five-phase permanent magnet motor a , i b , i c , i d , i e , the matrix transformation is performed on the sampled current to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com