Electronic direct-seeding film laminating machine for rice

A mulching machine and electronic technology, applied in the direction of hole seeding machine, seeding, planting method, etc., can solve the problems of difficulty in changing hole spacing, high precision and low mechanical failure, and asynchronous forward speed of mulching film delivery speed. The effect of rice organic production and labor productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A kind of rice electronic direct-broadcast laminating machine of the present embodiment is made up of mechanical, electric two parts.

[0035] 1. Mechanical part

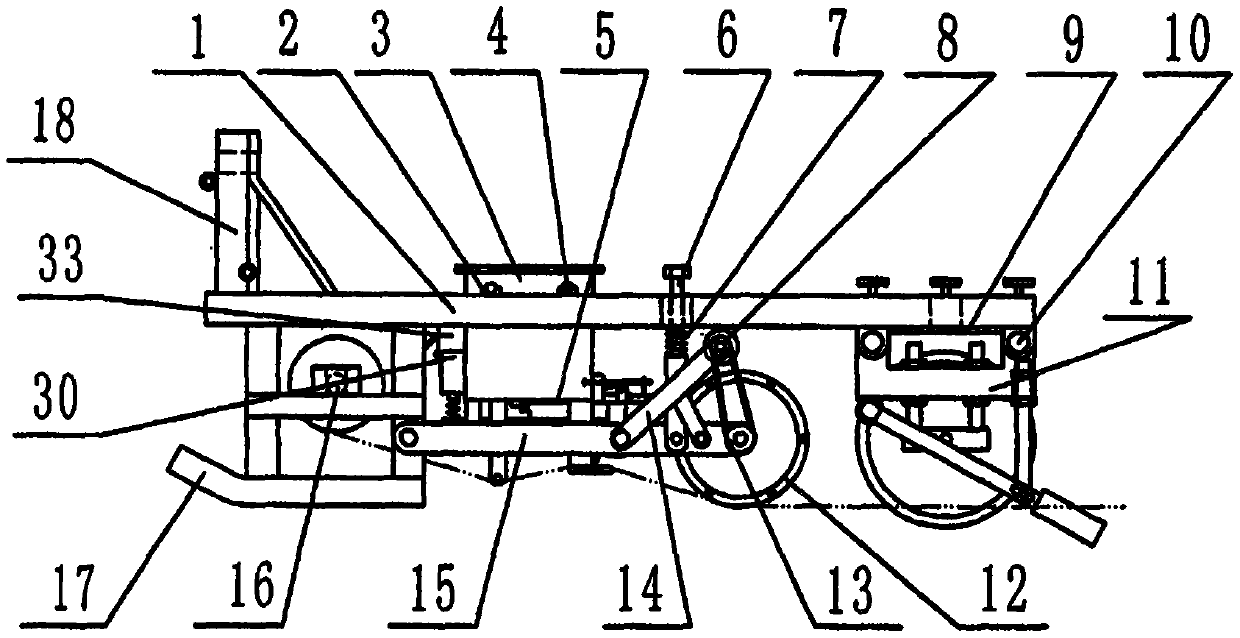

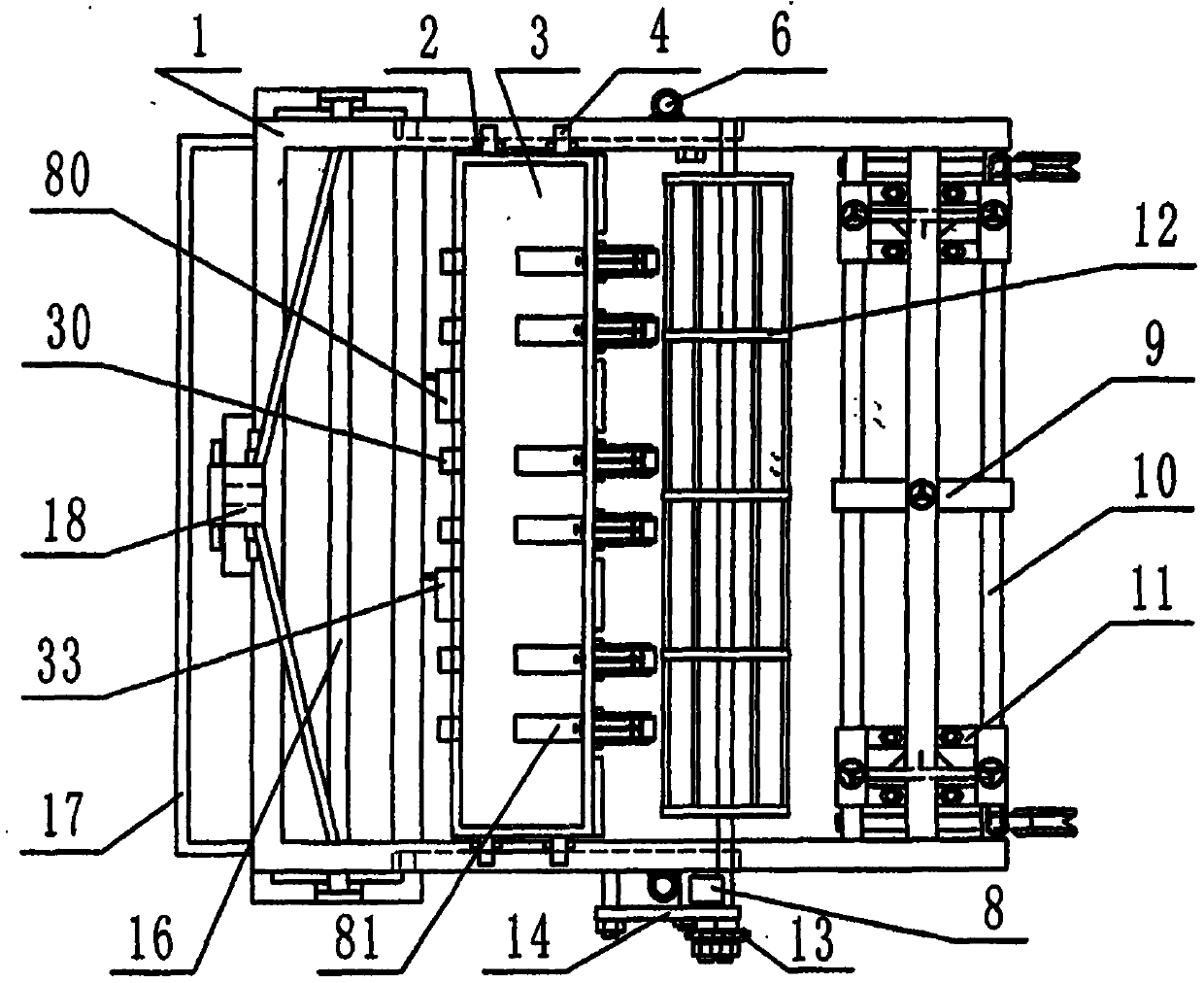

[0036] like figure 1 , figure 2 Shown, hanger 18, boat plate 17, kind of box 3, lamination roll cage pull bar 15, mulch reel 16, slide rail fixed mount 9, lamination edge device slide rail 10 are equipped with on frame 1.

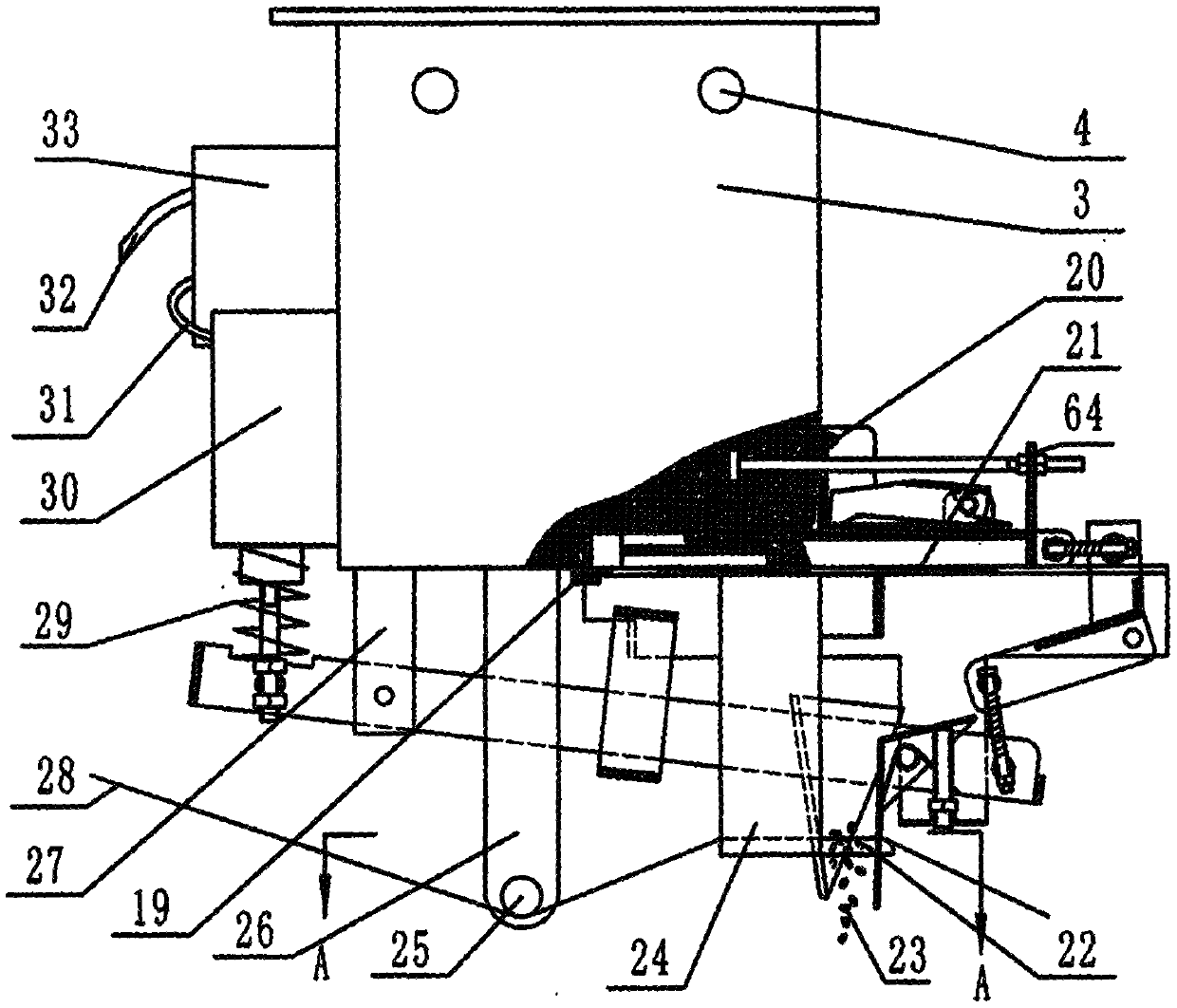

[0037] like figure 1 , figure 2 , image 3 , Figure 5 Shown, distribution box one 33 is housed on the seed box 3, and voltage stabilizing power supply circuit 75, microprocessor circuit 76, switch drive circuit 77, switch circuit 78, actuator circuit 79 are installed in distribution box one 33; The power supply circuit 75 is connected to the traction locomotive power supply through the power supply line 32 , and the actuator circuit 79 is connected to the electromagnet 30 through the wire 31 . Also equipped with distribution box two 80 on the kind box 3, the switch S9-S14 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com