Method for processing coconut cream

A processing method and coconut milk technology, applied in the field of food processing, can solve the problems of high product quality risk, complex production process, easy oxidation of products, etc., and achieve the effects of avoiding oil accumulation, simple processing technology and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

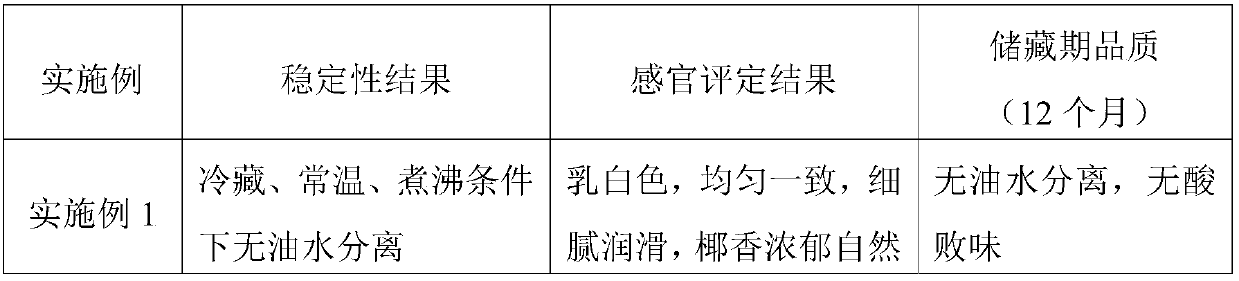

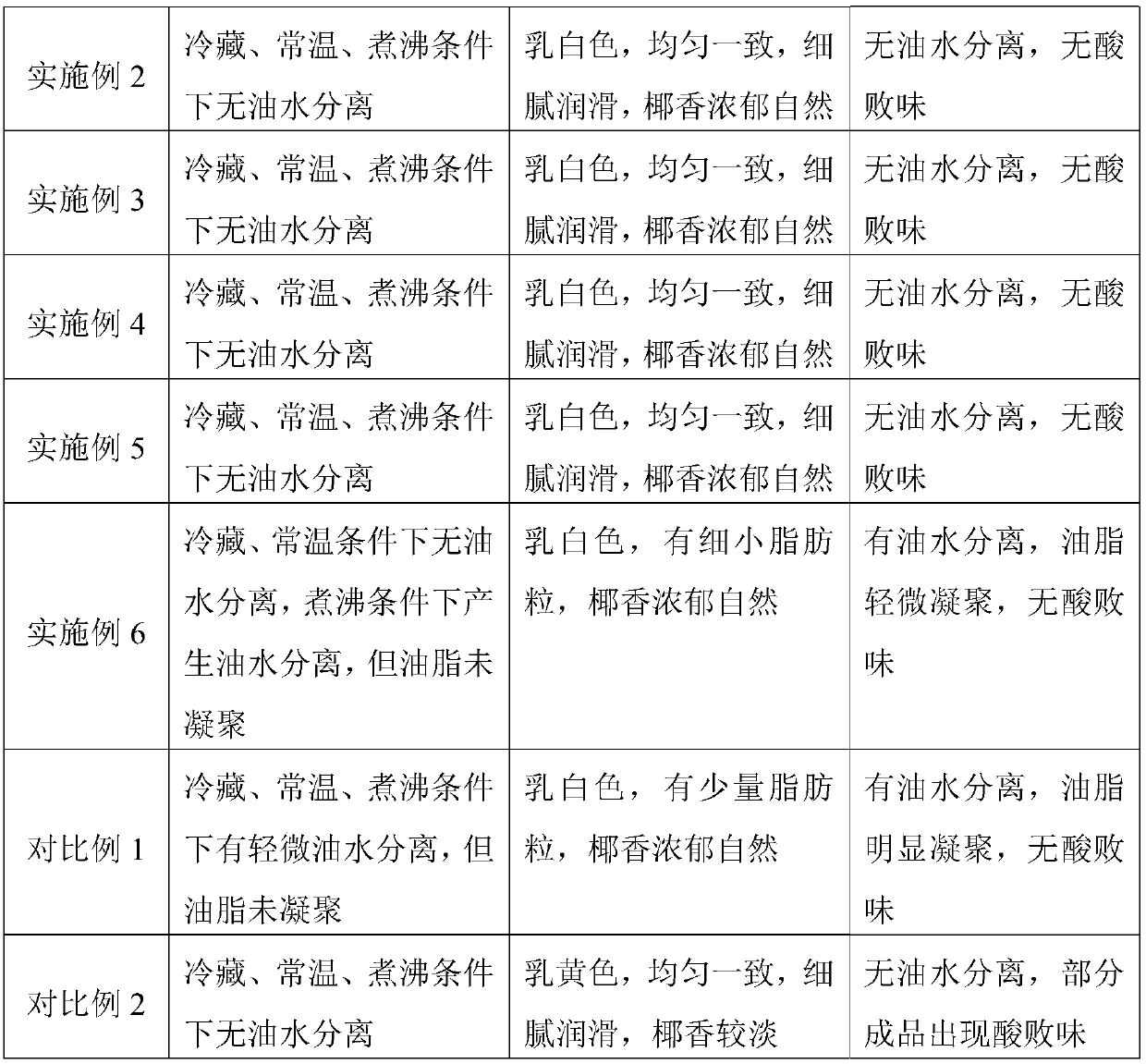

Examples

Embodiment 1

[0026] A kind of coconut milk processing method, specifically comprises the steps:

[0027] Step 1: Fresh coconuts are shelled and peeled to obtain coconut pulp, crushed with water, ground into coconut meat of about 2 mm, then transported to a press, and filtered to separate the coconut dregs to obtain coconut milk.

[0028] Step 2: Pasteurize the coconut milk prepared in the above step 1), the sterilization temperature is 50° C., the sterilization time is 30 minutes, and it is rapidly cooled to 10° C. after sterilization for subsequent use.

[0029] Step 3: Dissolve the composite water-soluble dietary fiber composed of xanthan gum and guar gum (mass ratio: 3:2) with hot water at 90°C. The amount of composite water-soluble dietary fiber added is 0.2% of the mass of coconut milk, fully dissolved Evenly, and cooled to 10 ℃, set aside.

[0030] Step 4: drop the colloid obtained in the above step 3) into the coconut milk prepared in step 2) and mix and stir to obtain highly stabl...

Embodiment 2

[0033] A kind of coconut milk processing method, specifically comprises the steps:

[0034] Step 1: Fresh coconuts are shelled and peeled to obtain coconut pulp, crushed with water, ground into coconut meat of about 2 mm, then transported to a press, and filtered to separate the coconut dregs to obtain coconut milk.

[0035] Step 2: Pasteurize the coconut milk prepared in the above step 1), the sterilization temperature is 65° C., the sterilization time is 20 minutes, and it is rapidly cooled to 6° C. after sterilization for subsequent use.

[0036] Step 3: Dissolve the composite water-soluble dietary fiber composed of xanthan gum, guar gum, and carrageenan (mass ratio: 6:4:1) with hot water at 95°C. 0.1%, fully dissolved evenly, and cooled to 6°C for later use.

[0037] Step 4: drop the colloid obtained in the above step 3) into the coconut milk prepared in step 2) and mix and stir to obtain highly stable coconut milk.

[0038] Step 5: UHT sterilize the coconut milk prepare...

Embodiment 3

[0040] A kind of coconut milk processing method, specifically comprises the steps:

[0041] Step 1: Fresh coconuts are shelled and peeled to obtain coconut pulp, crushed with water, ground into coconut meat of about 3mm, then transported to a press, and filtered to separate the coconut dregs to obtain coconut milk.

[0042] Step 2: Pasteurize the coconut milk prepared in the above step 1), the sterilization temperature is 80° C., the sterilization time is 15 minutes, and it is rapidly cooled to 4° C. after sterilization for subsequent use.

[0043] Step 3: Dissolve the composite water-soluble dietary fiber composed of xanthan gum, guar gum, carrageenan, and konjac gum (6:3:2:1 in mass ratio) with hot water at 90°C, the amount of composite water-soluble dietary fiber to be added It is 0.05% of the mass of coconut milk, fully dissolved evenly, and cooled to 4°C for later use.

[0044] Step 4: drop the colloid obtained in the above step 3) into the coconut milk prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com