Activated carbon material crushing device

A technology of activated carbon and crushed materials, which is applied in the direction of grain processing, etc., can solve problems such as fire, factory production safety hazards, and impact on health, and achieve the effect of eliminating dust explosions and eliminating potential hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings of the embodiments of the present invention.

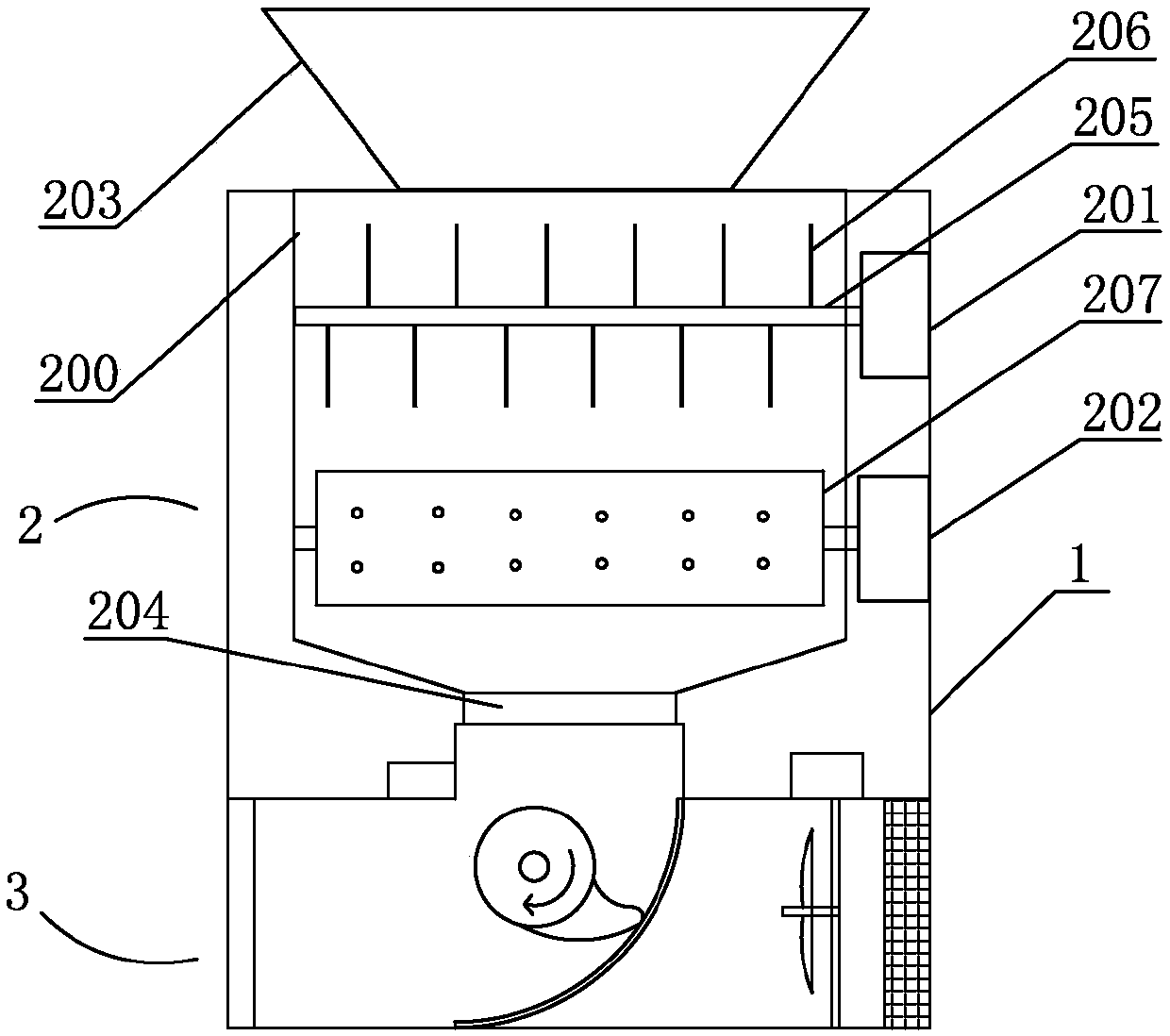

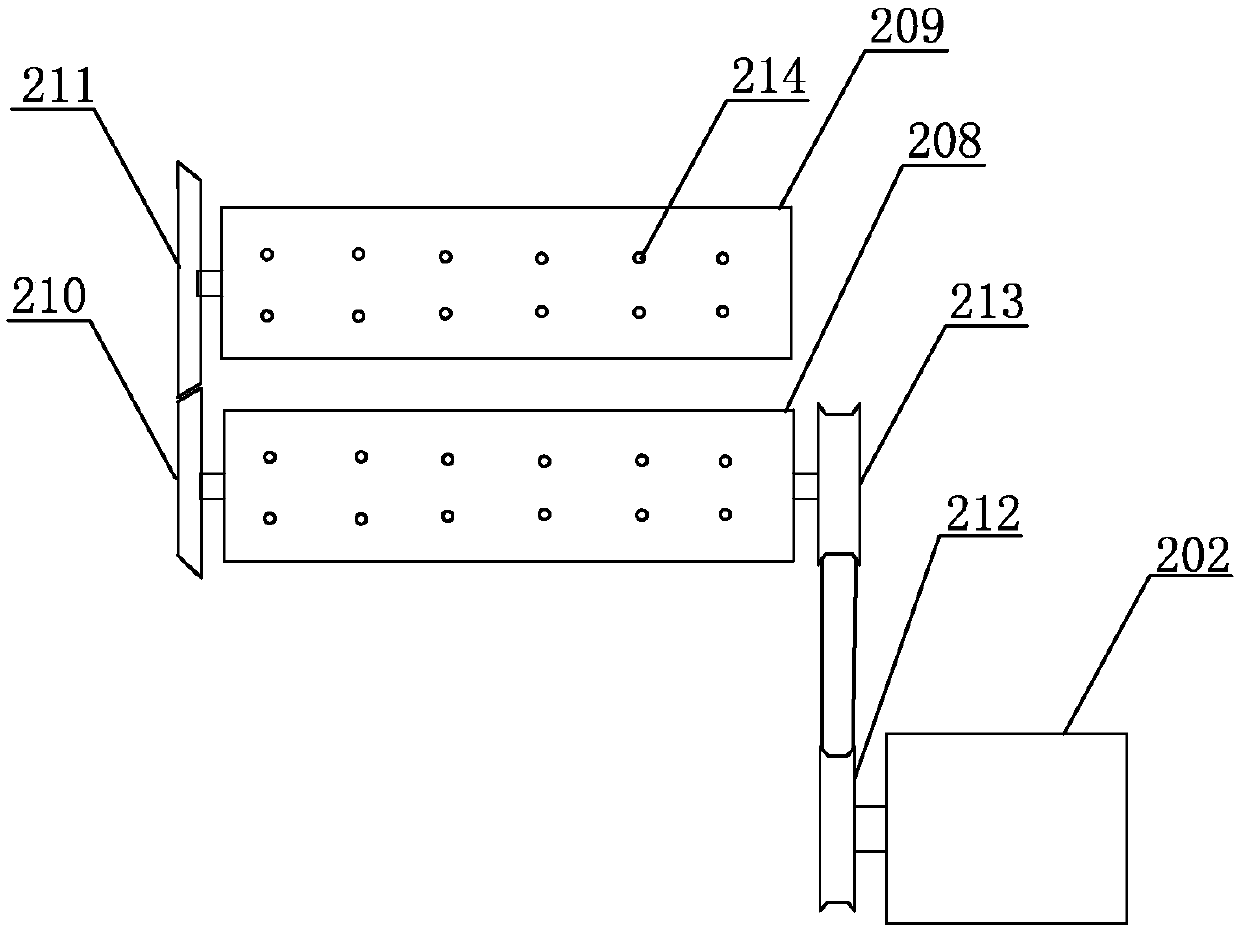

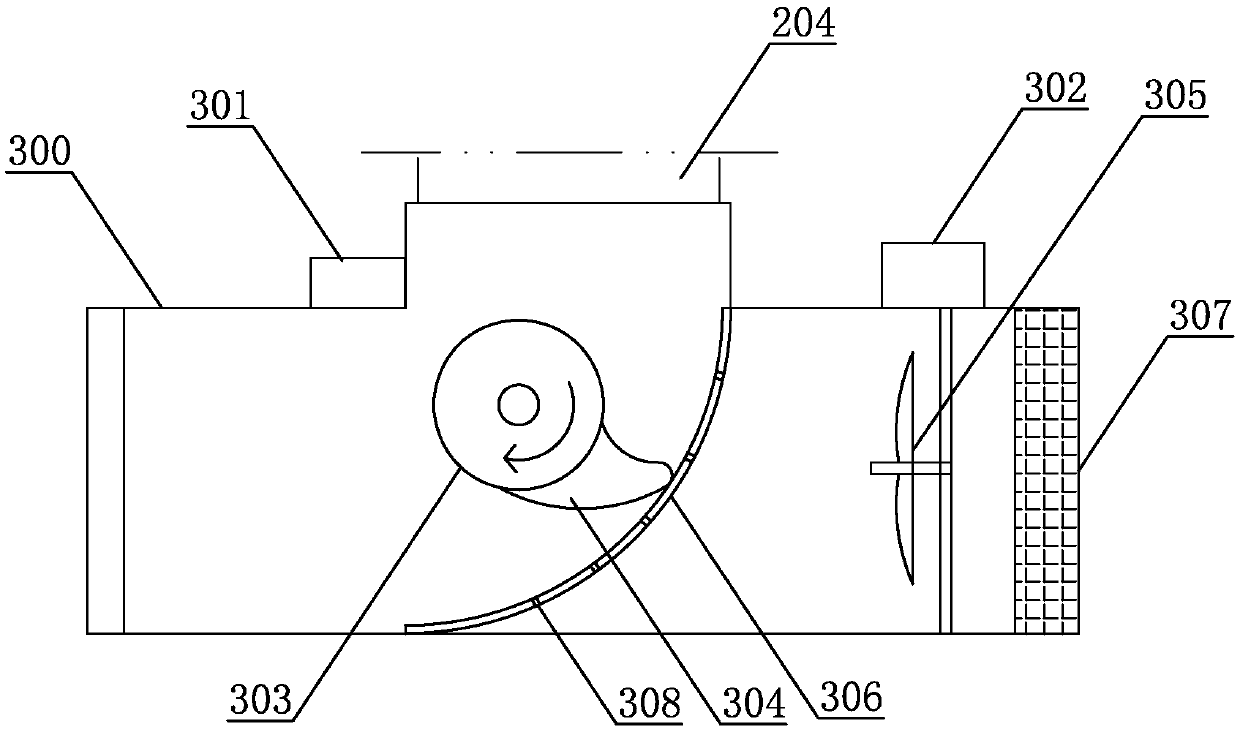

[0019] Such as figure 1 , figure 2 with image 3 Shown

[0020] The technical solution adopted by the present invention is to provide an activated carbon raw material crushing device with the following structure, which includes a frame 1 and a crushing mechanism 2 and a dust removal mechanism 3 arranged on the frame 1. The crushing mechanism 2 is used for To pulverize the activated carbon raw materials, the dust removal mechanism 3 is used to remove dust in the pulverized activated carbon particles; the crushing mechanism 2 includes a crushing box 200, a first motor 201 and a second motor 202 arranged on the frame 1, and The top of the feed box 200 is provided with a feed port 203, and the bottom is provided with a feed port 204. A cutter shaft 205 is rotatably connected to the scrap box 200. A plurality of blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com