Kitchen garbage treating machine

A food waste and processing machine technology, applied in the direction of grain processing, solid waste removal, etc., can solve the problems of clogged drainage pipes, complicated processing procedures, low production efficiency, etc., to reduce the probability of clogging, improve the filtering effect, and avoid The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

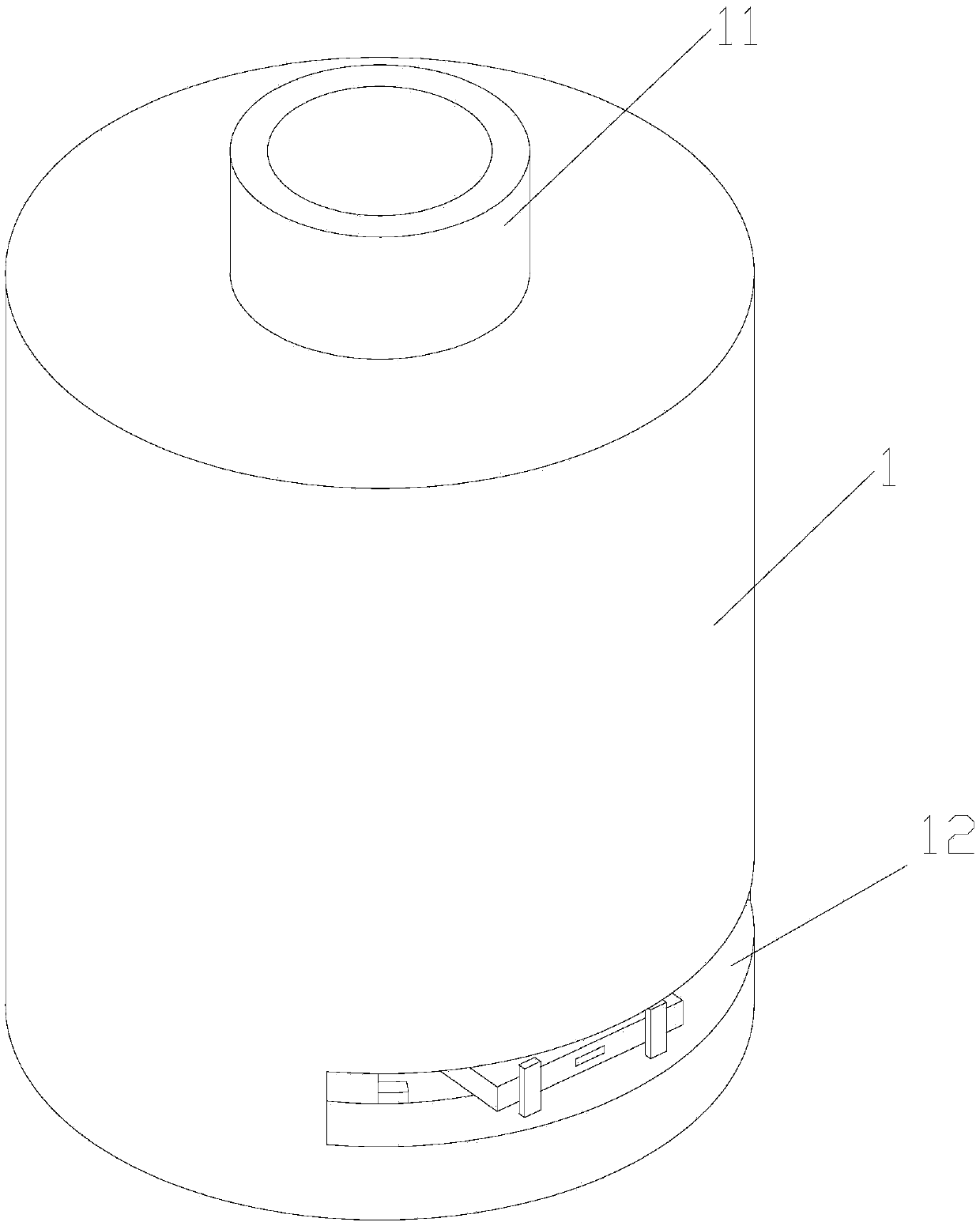

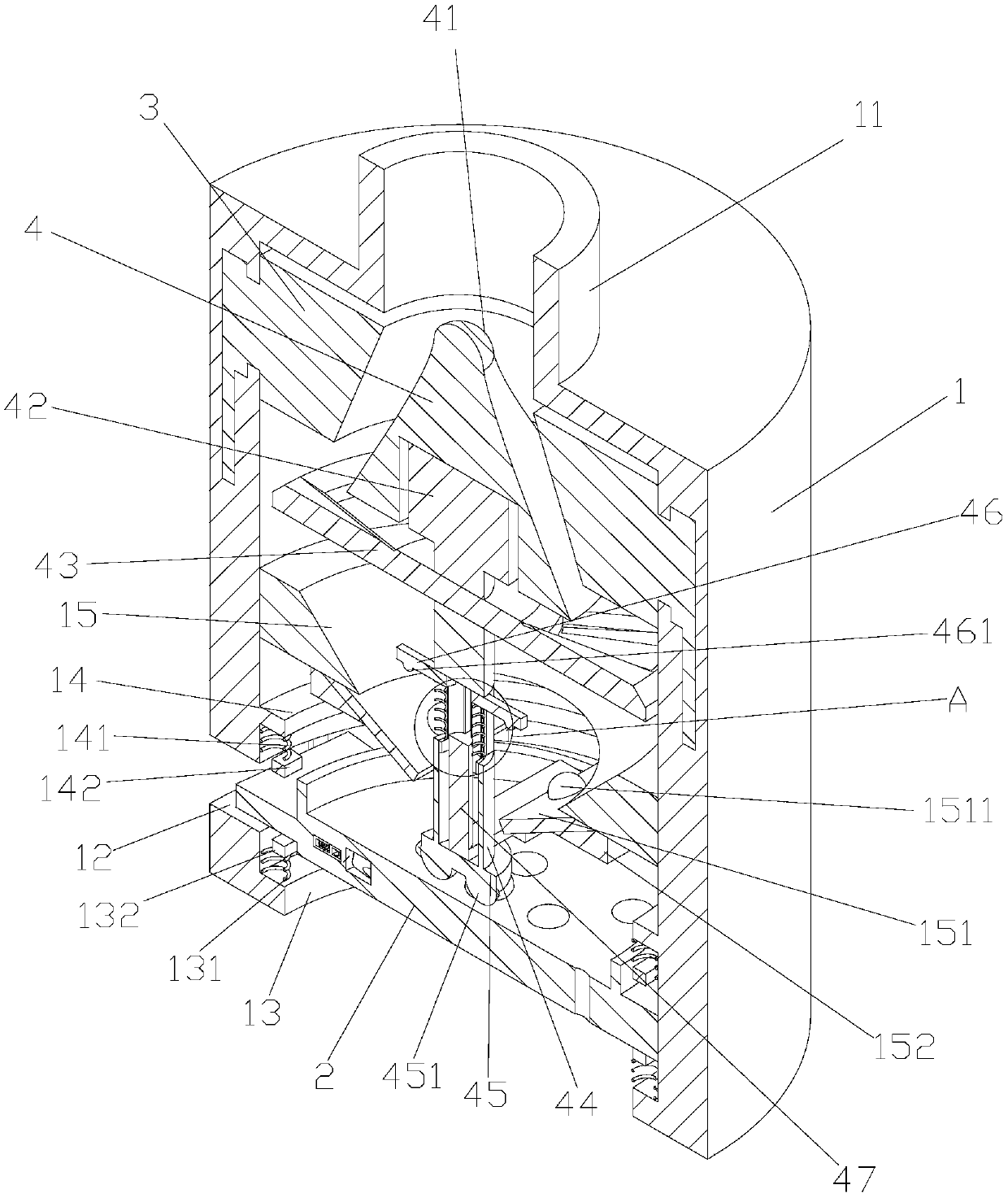

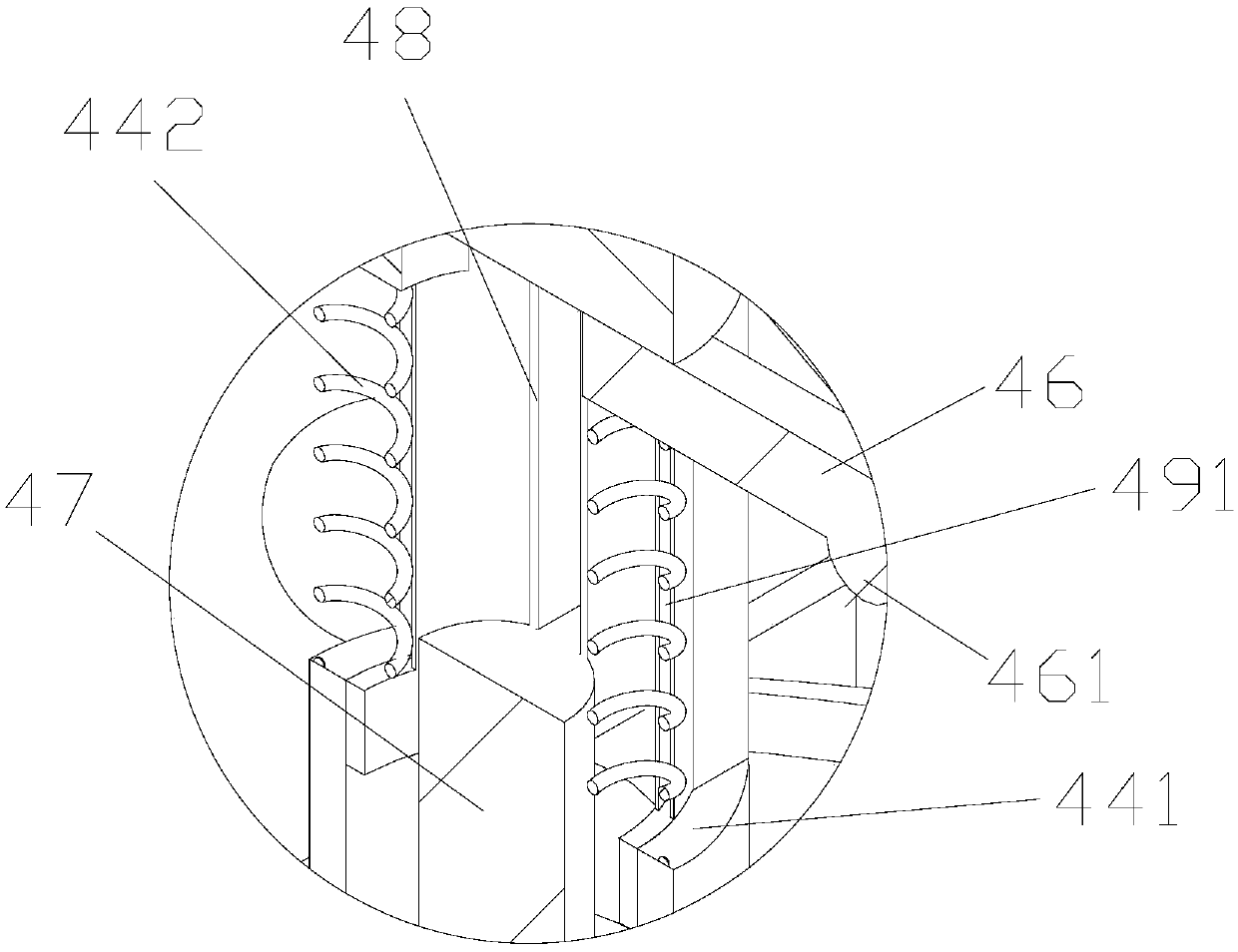

[0031] Such as Figure 1-15 As shown, a kind of food waste disposer comprises processing box 1, the crushing device that is arranged in processing box 1 and the filter plate 2 that is arranged at the bottom of described crushing device, and filter plate is detachably connected in processing box, and described The top of the treatment box 1 is provided with a feed pipe 11, and the bottom of the treatment box 1 is provided with a discharge port, and the waste water carrying garbage enters from the feed pipe and is discharged from the discharge port; The matching opening 12 of the filter plate 2, the filter plate can be taken out from the opening to clean up the rubbish on the filter plate; The through hole 431 and the crushing knife 432 arranged on the inner wall of the first through hole 431, the first through hole is fan-shaped, and the first through hole is multiple, distributed on the connecting plate in a circle, and enters from the feed pipe to the The garbage in the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com