Spiral blade wear resisting layer alloy overlaying process

A helical blade and wear-resistant layer technology, which is applied in the field of alloy surfacing welding technology of the helical blade wear-resistant layer, can solve the problems of general wear resistance, short service life, complicated processing, etc., and achieve high comprehensive performance of wear resistance and corrosion resistance, Extend the service life and reduce the effect of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

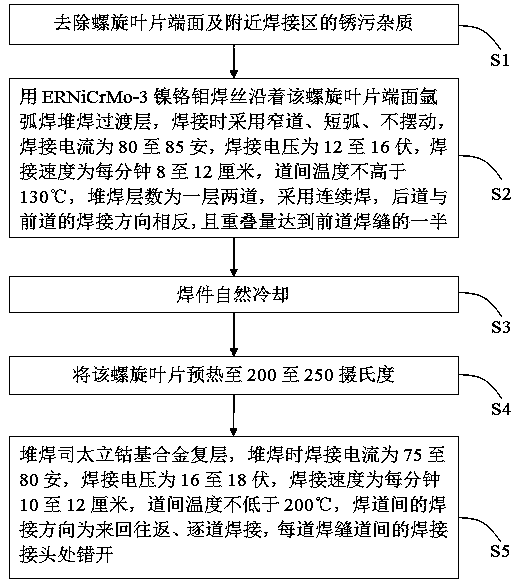

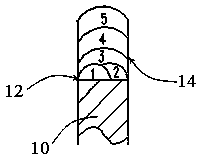

[0019] Please refer to figure 1 and figure 2 , figure 1 It is a flow chart of the alloy overlay welding process for the wear-resistant layer of the spiral blade according to an embodiment of the present invention, figure 2 It is a schematic diagram of the surfacing section structure of an embodiment of the present invention. The alloy surfacing process of the wear-resistant layer of the spiral blade of the present invention includes the following steps.

[0020] S1, remove the rust impurities on the end surface of the spiral blade 10 and the nearby welding area, such as oil, rust, water and other impurities. The main body of the spiral blade can be made of duplex steel 2205 material.

[0021] S2, use ERNiCrMo-3 nickel-chromium-molybdenum welding wire to weld th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com