Optical fiber and water guide laser coupling processing device and system

A processing device and optical fiber technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of unsatisfactory laser processing depth, low laser total reflection efficiency, low laser output power, etc., and achieve stable laminar flow characteristics , Improve the coupling power of light and liquid, and improve the effect of coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

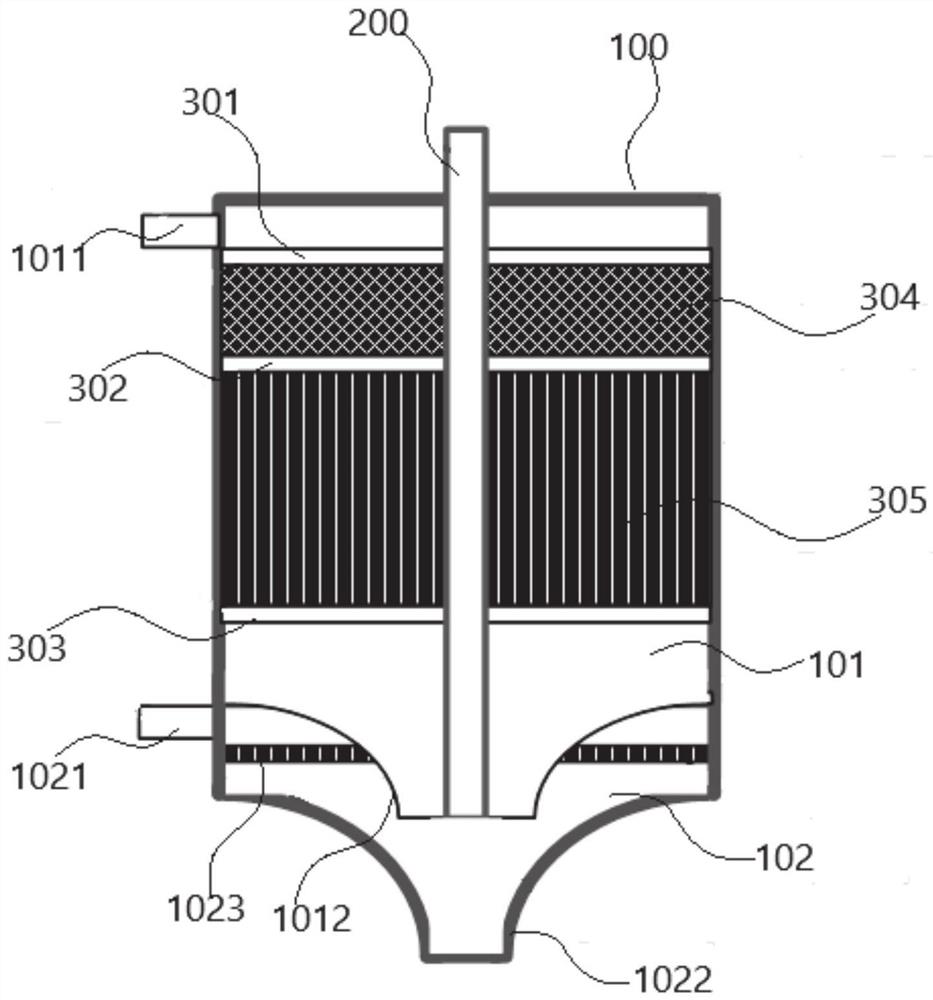

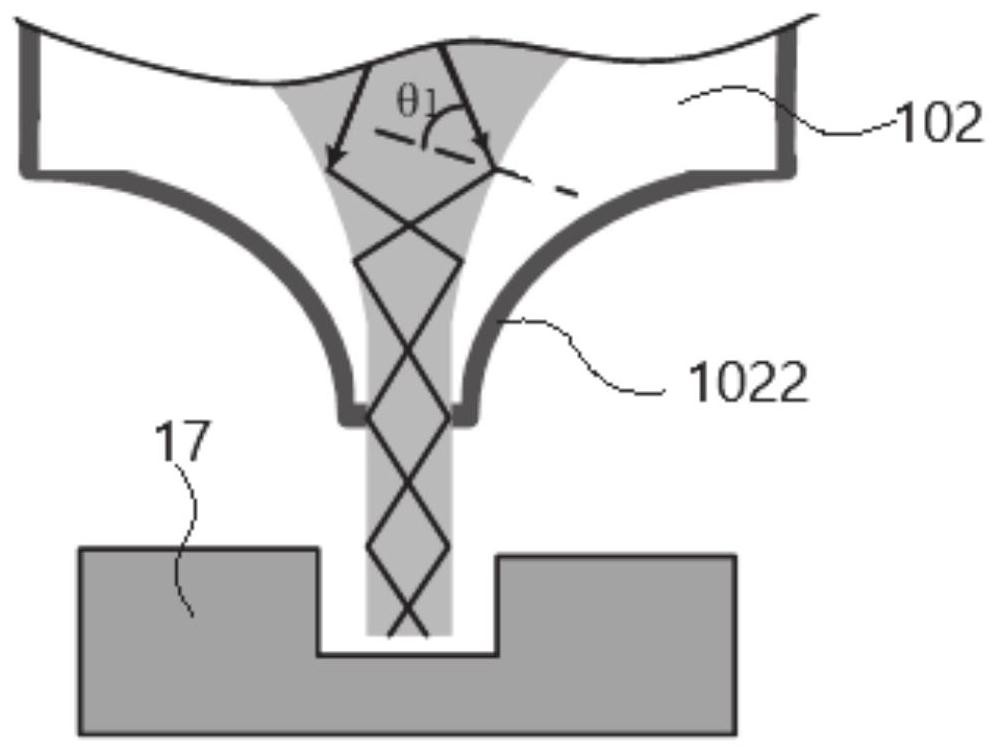

[0077] figure 1 Schematic diagram of the structure of the optical fiber and water guide laser coupling processing device provided in this embodiment, figure 2 The schematic diagram of water-guided laser transmission in the optical fiber and water-guided laser coupling processing device provided for this embodiment is combined below Figure 1~2 This embodiment will be specifically described.

[0078] Such as figure 1 As shown, the optical fiber and water-guided laser coupling processing device includes a laminar flow chamber 101 and a gas chamber 101 from top to bottom. In the laminar flow chamber 102, the first annular filter 301, the sponge body 304, the second annular filter 302, the guide tube 305, the third annular filter 303, and the layer The bottom end of the flow chamber 102 forms a first reduced diameter port. The optical fiber 200 is fixed in the laminar flow chamber 102 along the vertical direction, the upper end of the optical fiber 200 protrudes from the thro...

Embodiment 2

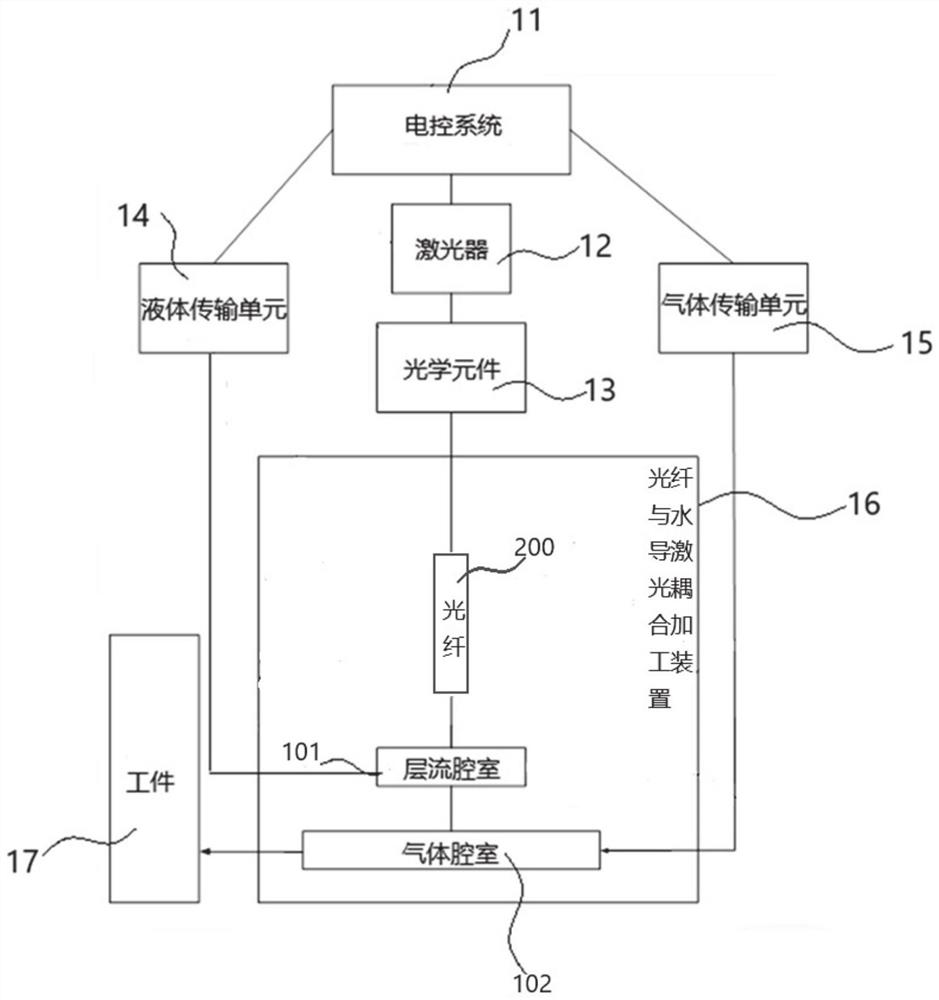

[0085] image 3 The structural frame diagram of the optical fiber and water guide laser coupling processing system provided for this embodiment, combined below image 3 This embodiment will be described.

[0086] Such as image 3 As shown, the optical fiber and water-guided laser coupling processing system includes: an electronic control system 11, a laser 12, an optical element 13, a liquid transmission unit 14, a gas transmission unit 15, and any of the optical fiber and water-guided laser coupling processing devices described above. 16;

[0087] The electric control system 11 is respectively electrically connected with the laser 12, the gas delivery unit 15 and the liquid delivery unit 14 for controlling the laser 12, the gas delivery unit 15 and the liquid delivery unit 14;

[0088] The optical element 13 is located between the laser 12 and the optical fiber and the water-guiding laser coupling processing device 16 for guiding the laser light generated by the laser 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com