A corn stalk briquetting device for uniform cutting

A corn stalk and uniform technology, which is applied in the direction of material forming presses, presses, cutting equipment, etc., can solve the problems of different lengths of finished products, loose and easy loose ends of block finished products, and achieve high cutting speed and no Easy to crush, neat and firm cut surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further detailed below in conjunction with the embodiments of the drawings.

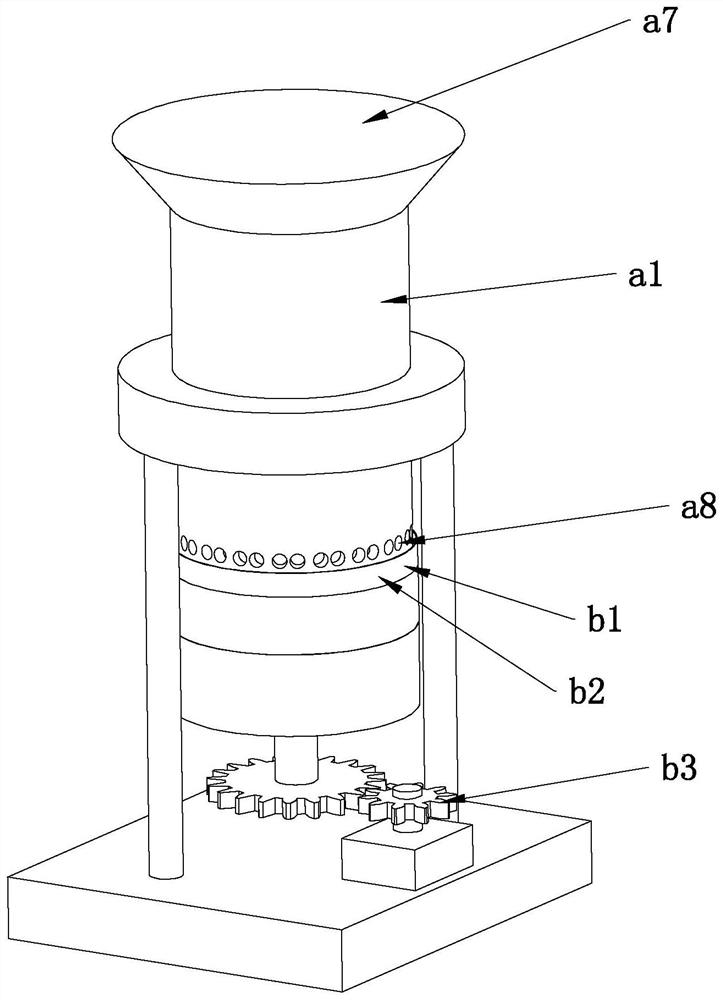

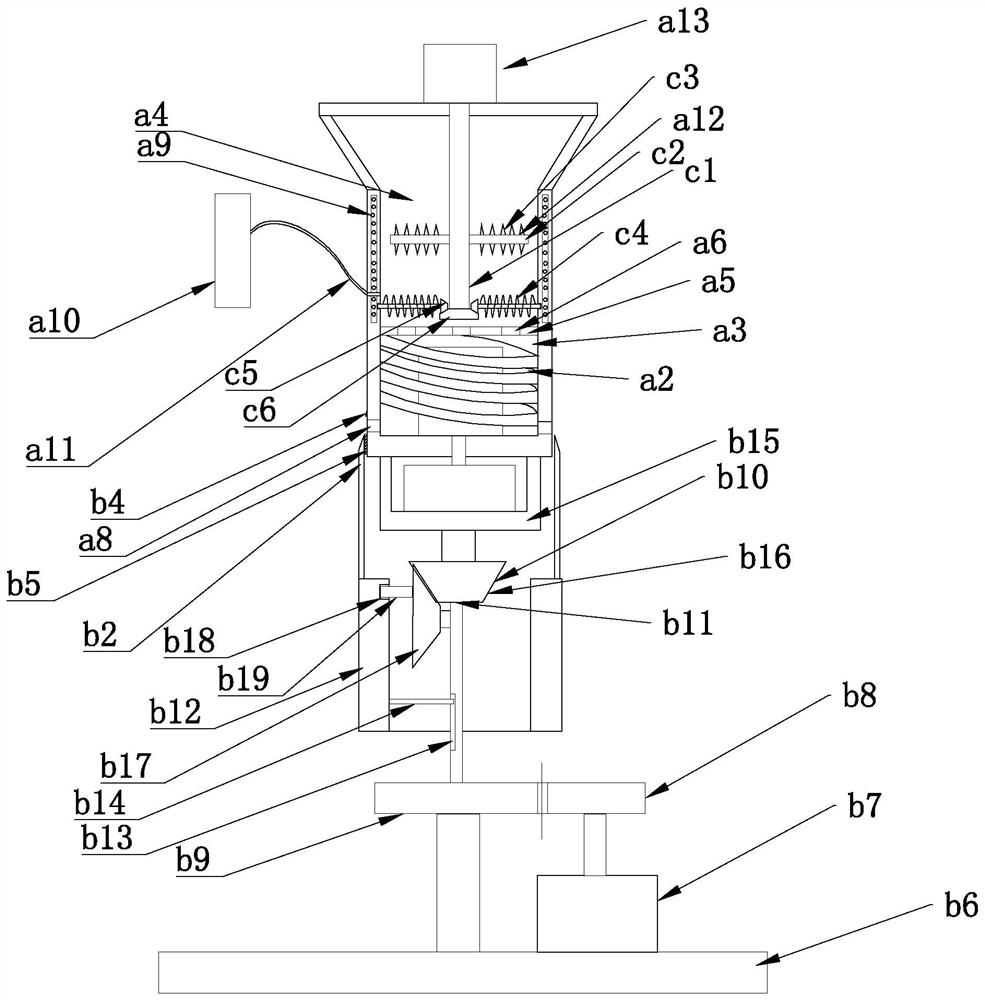

[0016] Such as Figure 1-2 The illustrated embodiment is illustrated: the present invention provides a uniformly cut corn stalk briquetting device, which includes a die seat a1, a compression assembly a2, and a heating device. The die seat a1 is preferably cylindrical, and the press The mold base a1 includes a compression chamber a3 and a softening and heating chamber a4. The opening of the softening and heating chamber a4 is provided with a cover, and the cover is provided with a feed port a7, which is cut into small pieces of straw powder Enter the softening and heating chamber a4 through the feed port a7. The softening and heating chamber a4 is arranged at the upper end of the compression chamber a3 and penetrates each other. The softening and heating chamber a4 and the compression chamber a3 are separated by a partition a5, so The partition a5 is provided with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com