nozzle

A nozzle and front-end technology, which is applied in the field of nozzles, can solve the problem that the needle-shaped part does not have liquid-proof performance, and achieve the effects of reliable small amount of dripping, reliable protection, and prevention of liquid residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

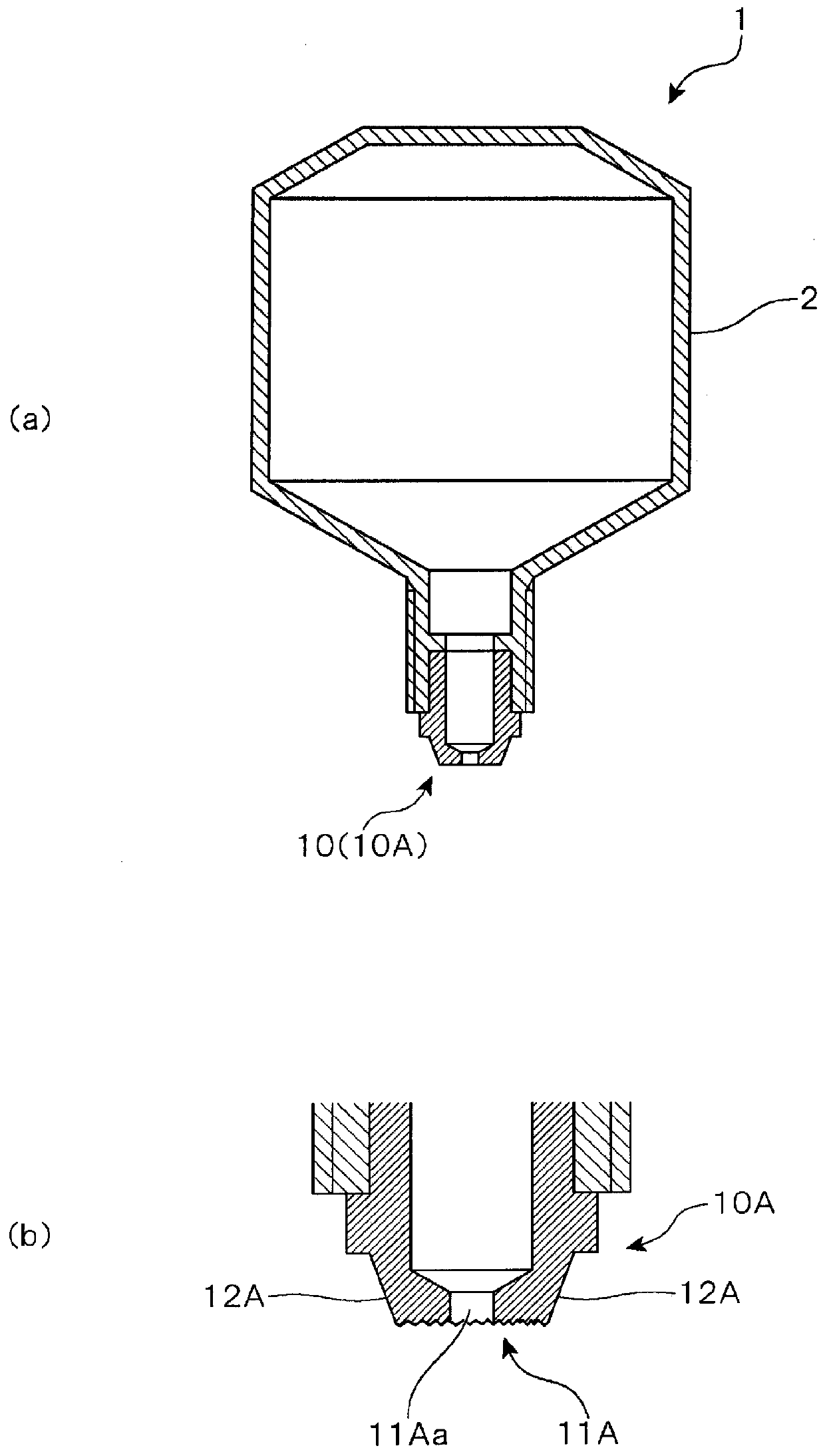

[0108] In the nozzle 10A of the first embodiment, the surface of the tip portion 11A of the nozzle 10A is fluorinated and roughened by a predetermined method.

[0109] First, for the nozzle 10A formed of a plastic molded body made of a non-fluorine-based resin, fluorine atoms are incorporated in the molecular chain of the non-fluorine-based resin constituting the plastic molded body.

[0110] In addition, the surface of the tip portion 11A of the nozzle 10A thus fluorinated can be roughened as necessary.

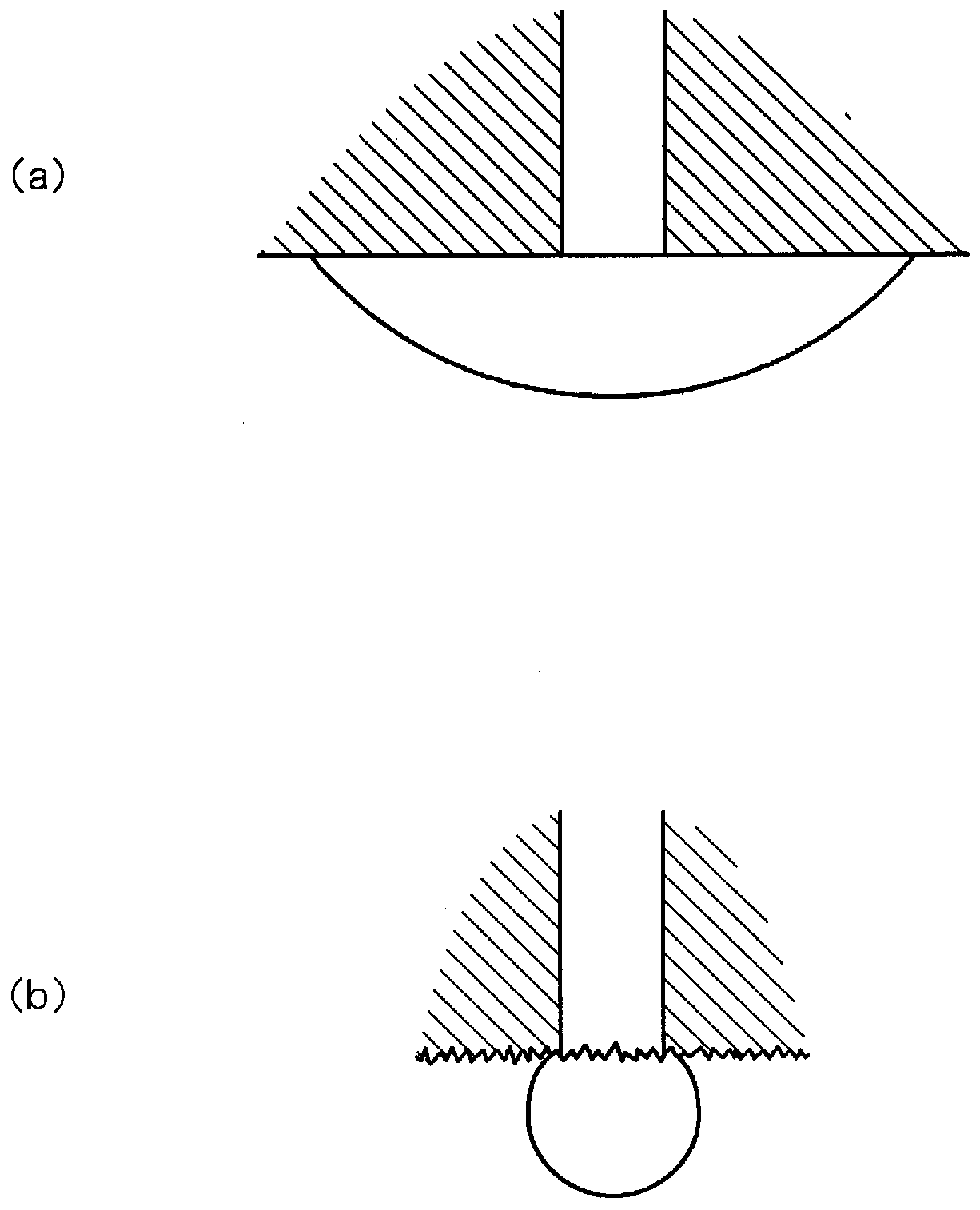

[0111] Thus, by fluorinating and roughening the front end portion 11A of the nozzle 10A, the liquid repellency of the nozzle 10A can be improved (see image 3 , 4 ), it is possible to prevent the liquid (eye drops) injected from the container main body 2 from being wetted in a wide range with respect to the front end 11A of the nozzle 10A, and by adjusting and setting the inner diameter of the opening 11Aa, it is possible to arbitrarily set the The amount of dripping liqui...

no. 2 approach

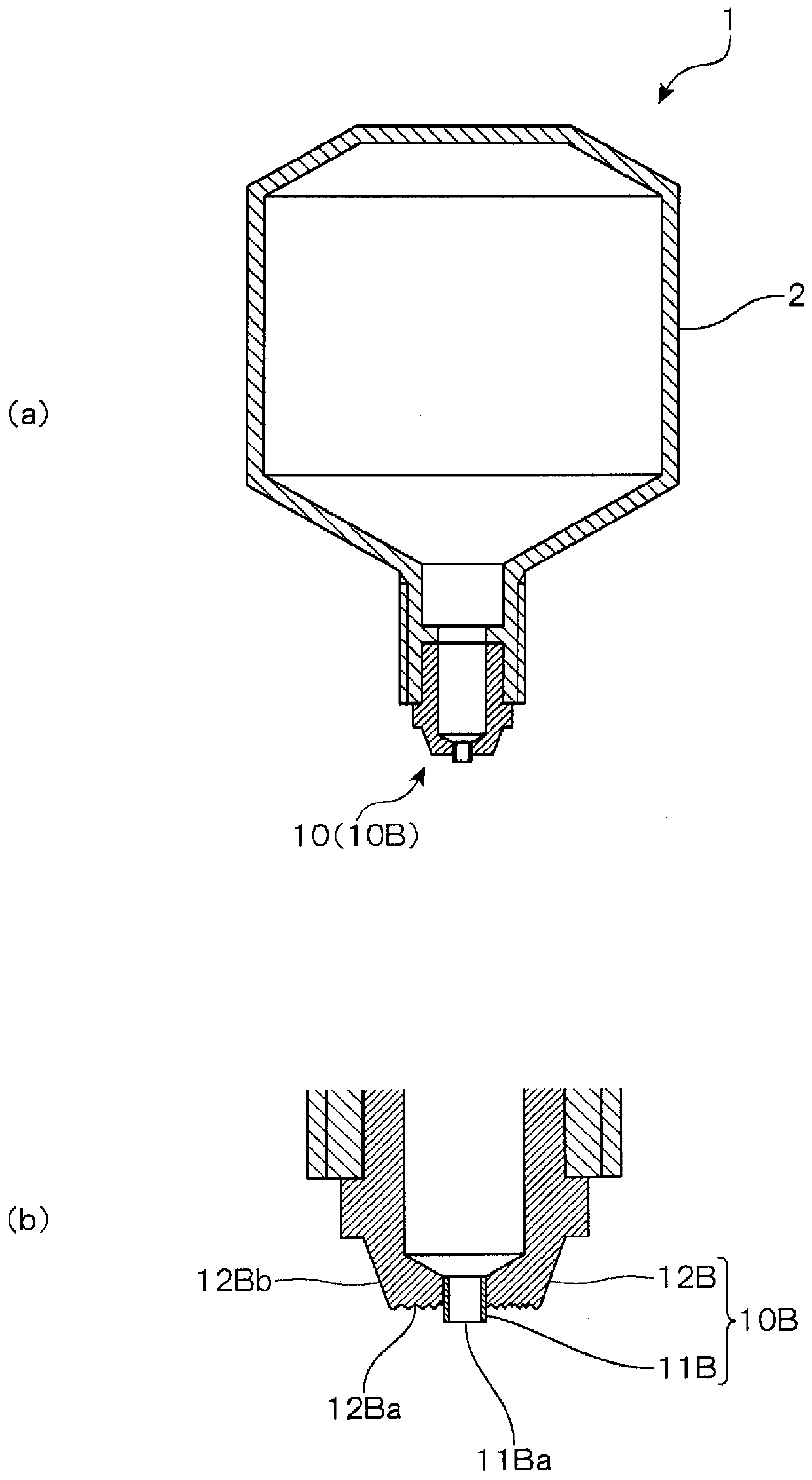

[0120] The basic structure, material, etc. of the nozzle 10B of the second embodiment are substantially the same as those of the nozzle 10A of the first embodiment described above.

[0121] Furthermore, the structure of the nozzle tip of the nozzle 10B of the second embodiment is different from that of the nozzle 10A of the first embodiment.

[0122] That is, the front end surface of the nozzle 10B of the second embodiment has a first surface 11Ba positioned at the nozzle center side and a second surface 12Ba continuous with the outer peripheral side of the first surface 11Ba, and the first surface 11Ba and the second surface 12Ba are separated by a surface. Surface configurations having different free energies, specifically, the second surface 12Ba has a structure having higher liquid repellency than the first surface 11Ba.

[0123] More specifically, in figure 2 In the example shown, the nozzle 10B is comprised by combining the 1st drip part 11B and the 2nd drip part 12B w...

Embodiment

[0377] Hereinafter, an embodiment of the nozzle of the present invention will be described.

[0378] It should be noted that the present invention is further described through the following examples, but the present invention is not limited by the following examples.

[0379] [first embodiment]

[0380] First, an example of the nozzle 10A according to the first embodiment of the present invention will be described.

[0381] Table 1 below shows Examples 1-3 and Comparative Examples 1-3 of the nozzle of the present invention.

[0382] [Table 1]

[0383]

[0384] Examples 1-3 and Comparative Examples 1-3 shown in Table 1 were carried out under the following conditions.

[0385] (1) Test sample

[0386] §Nozzle body

[0387] ·Material

[0388] ·Low-density polyethylene

[0389] ·Level: LJ8041

[0390] ·Size: diameter 10mm x length 10mm

[0391] · Opening diameter: 0.1, 0.2, 0.3, 0.4mm

[0392] · Nozzle body manufacturing method

[0393] - Obtaining the nozzle with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com